Hybrid-driven long-distance belt conveyor

A belt conveyor and hybrid drive technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of inconvenient layout and increase the volume of the motor drive system, so as to improve energy utilization, improve Activating braking performance, eliminating shock and vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

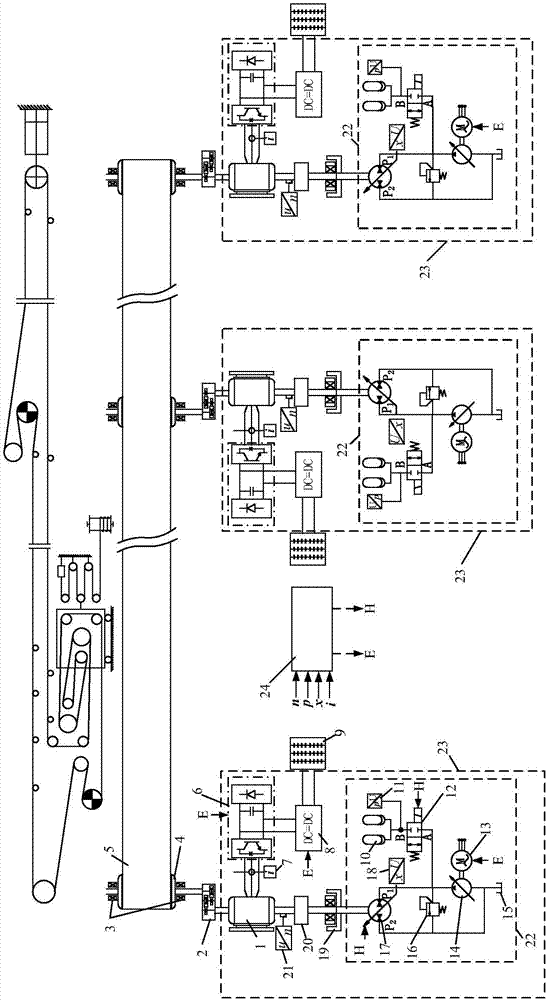

[0018] Introduce detailed technical scheme of the present invention below in conjunction with accompanying drawing:

[0019] Such as figure 1 As shown, the hybrid-driven long-distance belt conveyor includes a reducer 2, a gate control system 3, a driving roller 4, and a conveyor belt 5, and also includes a kinetic potential energy storage circuit and a motor composite drive system 23, a supercapacitor bank 9, and a control system. device 24, wherein the kinetic potential energy storage and transport loop and the motor composite drive system include: kinetic potential energy storage and transport loop 22, main drive motor 1, transmission 20, electromagnetic clutch 19, frequency converter 6, bidirectional DC-DC converter 8, current mutual inductance Device 7, speed sensor 21.

[0020] The kinetic potential energy storage and transportation circuit 22 includes an electric proportional four-quadrant hydraulic pump / motor 17, a safety valve 16, a constant pressure variable hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com