Environment-friendly waste gas exhausting system of vacuum sintering furnace for neodymium-iron-boron magnet industry

A vacuum sintering furnace, NdFeB technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as pollution and pipeline explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

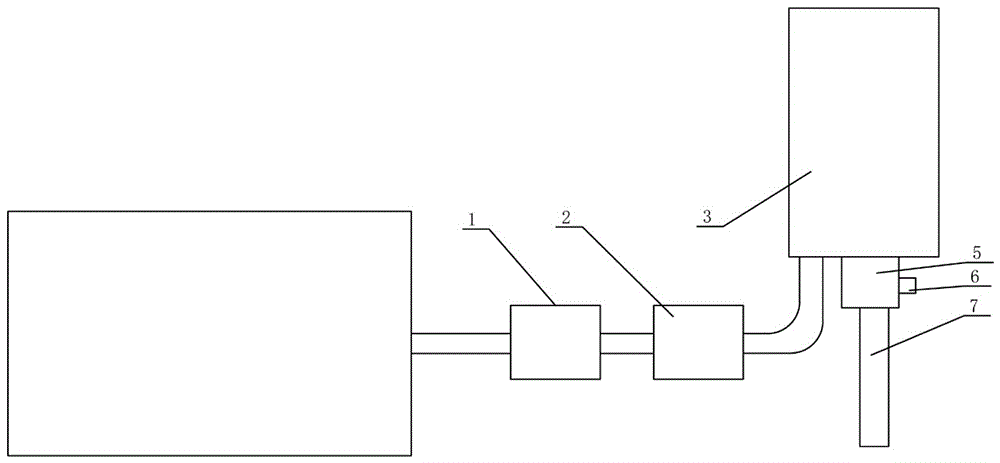

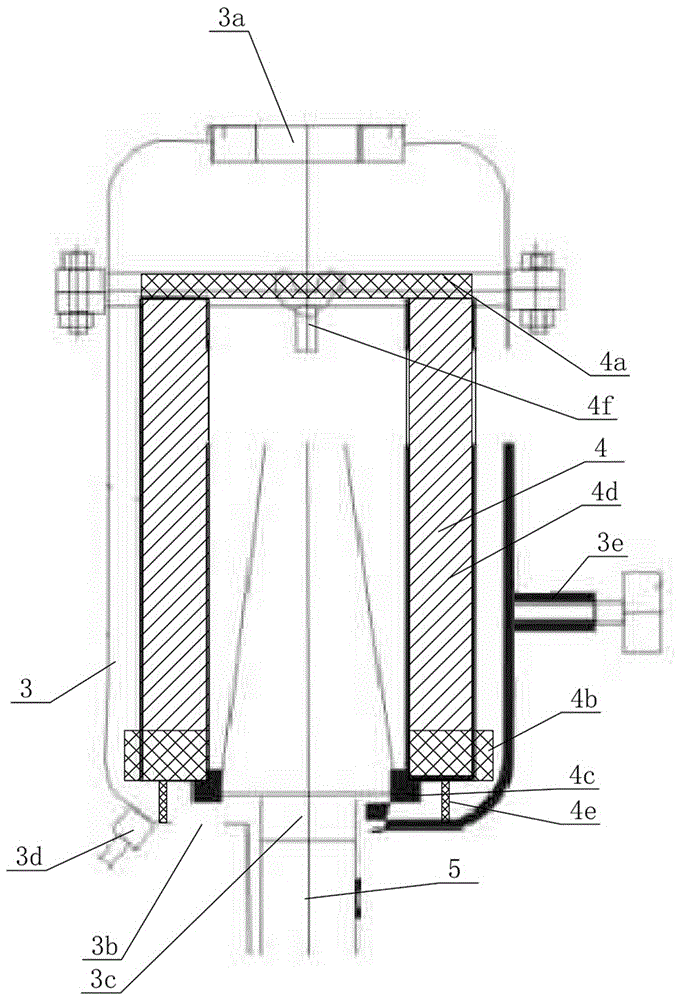

[0020] An environmentally friendly waste gas exhaust system for a vacuum sintering furnace used in the NdFeB magnet industry, comprising a Roots pump 1, a mechanical pump 2, a cylinder 3, a filter element 4, a stainless steel pipe 5, and a liquid discharge pipe 7.

[0021] The input end of the Roots pump 1 is connected to the vacuum sintering furnace through a pipeline, and the output end is connected to the mechanical pump 2 through a pipeline; the output end of the mechanical pump 2 is connected to the air inlet 3b of the cylinder 3 .

[0022] The cylinder 3 is hollow to form a cavity for accommodating the filter element 4; the cylinder 3 is provided with an air outlet hole 3a at the top, and an air inlet hole 3b and a liquid discharge hole 3c at the bottom. An exhaust valve 3d is installed on the side wall of the cylinder 3 .

[0023] The filter element 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com