Roughened copper foil, copper foil provided with carrier, copper-clad laminated sheet, and printed wiring board

A technology of printed circuit board and carrier copper foil, which is applied in the direction of printed circuit, printed circuit manufacturing, printed circuit components, etc., and can solve the problems of poor formation of micro-circuits and reduced circuit intervals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] The present invention will be described more specifically by the following examples.

example 1~6

[0076] Preparation and evaluation of the roughened copper foil with carrier foil were performed as follows.

[0077] (1) Production of carrier foil

[0078] A copper sulfate solution having the composition shown below was used as the copper electrolyte; a titanium rotating electrode having an arithmetic average surface roughness Ra (according to JIS B 0601: 2001) of 0.20 μm was used as the cathode; DSA (dimensional stability anode), at a solution temperature of 45°C and a current density of 55A / dm 2 Electrolysis was carried out under the hood to obtain an electrolytic copper foil with a thickness of 12 μm as a carrier foil. At this time, as the rotating cathode, an electrode whose surface was polished with #1000 polishing to adjust the surface roughness was used. The ten-point average roughness Rzjis of the electrode-side surface of the obtained carrier foil was measured in accordance with JIS B0601:2001, and it was 0.9 μm. In addition, the ten-point average roughness Rzjis...

example 7

[0132] Example 7 (Compare)

[0133] In the roughening treatment, the electric quantity Q in the plating process of the first stage 1 Relative to the electric quantity Q in the plating process of the second stage 2 ratio (Q 1 / Q 2 ) was less than 1.5, except that, it performed similarly to the procedure described about Examples 1-6, and performed preparation and evaluation of the tape carrier roughening process copper foil.

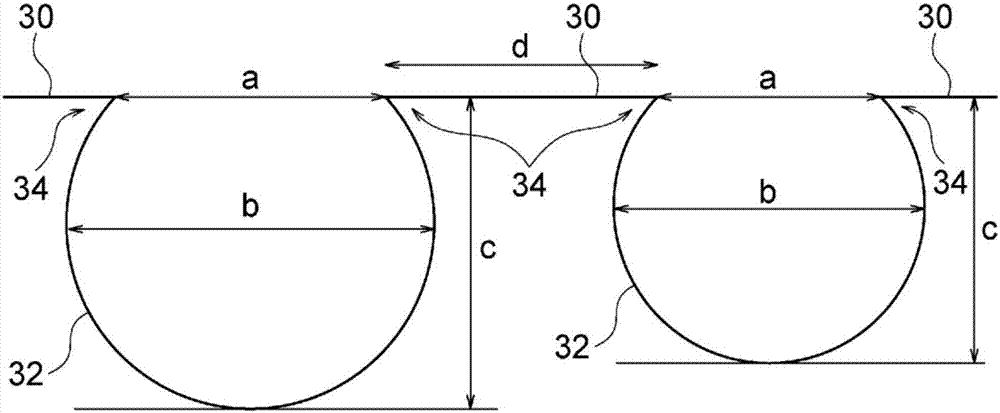

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com