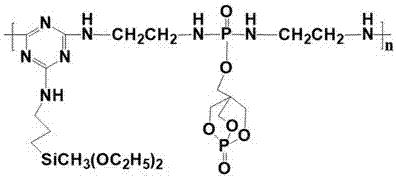

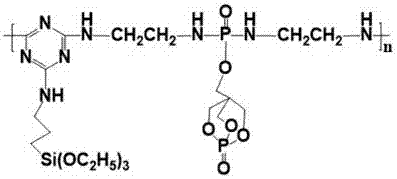

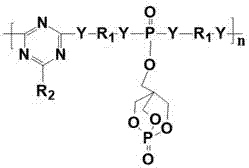

Phosphorus-nitrogen-silicon intumescent flame retardant containing triazine ring and cage structure and synthesis method of intumescent flame retardant

A technology of intumescent flame retardant and synthesis method, which is applied in the field of environmentally friendly halogen-free flame retardant products, can solve the problems of insufficient proportion, char formation performance and flame retardancy performance, etc., and achieve reasonable proportion and good char formation Ability to promote the effect of charring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The synthesis steps of phosphorus-nitrogen-silicon intumescent flame retardant containing triazine ring and cage structure are as follows:

[0033] step one

[0034] Add 250mL of acetonitrile to 1000mL, cool to -10℃, add 153.33g (1mol) of phosphorus oxychloride (POCl 3 ) Stir and disperse, gradually add 180g (ie 1mol) of 1-oxyphospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane (PEPA) and 101.20g ( 1mol) of triethylamine, reacted for 4 hours to obtain the mono-substituted PEPA (POCl 2 -PEPA);

[0035] Step two

[0036] In another container, add 120.20g (2mol) of ethylenediamine, 50mL of acetonitrile and 202.40g (2mol) of triethylamine and mix, cool to -10°C, slowly add 296.83g (1mol) of PEPA-containing One yuan substitution (POCl 2 -PEPA), react for 6 hours, and separate the phosphorus-containing diamine intermediate;

[0037] Step three

[0038] Add 184.5g (1mol) of cyanuric chloride into a 1000mL three-necked flask equipped with reflux condenser, stirrer, and constant pres...

Embodiment 2

[0044] The synthesis steps of phosphorus-nitrogen-silicon intumescent flame retardant containing triazine ring and cage structure are as follows:

[0045] step one

[0046] Add 300mL acetonitrile to 1000mL, cool to 10°C, add 153.33g (1mol) phosphorus oxychloride (POCl 3 1) Stir and disperse, gradually add 1-oxyphospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane (PEPA) 180g (1mol) and 101.20g triethylamine (1mol) of acetonitrile solution, react for 1 hour to obtain the mono-substituted PEPA (POCl 2 -PEPA);

[0047] Step two

[0048] Add a mixture of 176.30g (2mol) of butanediamine, acetonitrile (50mL) and 202.40g (2mol) of triethylamine in another container, cool to 10°C, and slowly add dropwise the 296.83g (1mol) obtained in step 1 The unary substitution of PEPA (POCl 2 -PEPA), react for 3 hours, and separate the phosphorus-containing diamine intermediate;

[0049] Step three

[0050] Add 184.5g (1mol) of cyanuric chloride into a 1000mL three-necked flask equipped with reflux cond...

Embodiment 3

[0056] The synthesis steps of phosphorus-nitrogen-silicon intumescent flame retardant containing triazine ring and cage structure are as follows:

[0057] step one

[0058] Add 300mL acetonitrile to 1000mL, cool to 0℃, add 153.33g (1mol) of phosphorus oxychloride (POCl 3 ) Stir and disperse, gradually add 180g (1mol) of 1-oxyphospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane (PEPA) and 101.20g (1mol). ) Triethylamine, reacted for 2.5 hours to obtain the mono-substituted PEPA (POCl 2 -PEPA);

[0059] Step two

[0060] In another container, add 120.20g (2mol) of ethylenediamine, 50mL of acetonitrile, 202.40g (2mol) of triethylamine and mix them, cool to 0°C, and slowly add dropwise the 296.83g (1mol) obtained in step 1 ) The unary substitution of PEPA (POCl 2 -PEPA), react for 4.5 hours, and separate the phosphorus-containing diamine intermediate;

[0061] Step three

[0062] Add 184.5g (1mol) of cyanuric chloride into a 1000mL three-necked flask equipped with reflux condenser, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com