Process for producing saponin and rhamnose from turmeric

A technology of rhamnose and saponin, applied in the field of saponin extraction, can solve the problems of ineffective utilization of cellulose, interference with diosgenin hydrolysis, a large amount of waste water and waste residue, etc., to reduce the amount of steam, save the amount of steam, and facilitate the Delivery and added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

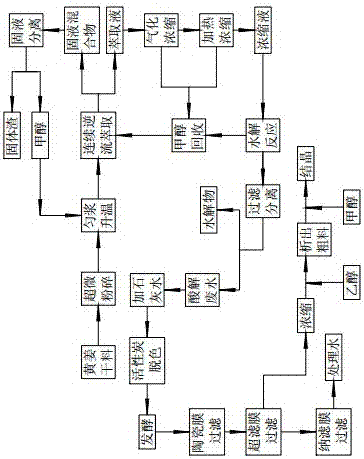

[0047] Such as figure 1 Shown: (1) Grind turmeric dry material and pass through a 100-mesh sieve;

[0048] The turmeric dry material is ultrafinely crushed and sieved through a 100-mesh sieve, wherein the water content of the turmeric dry material is less than or equal to 8%, so as to avoid excessive water content from hindering the extraction of saponins.

[0049] (2) Mix the sieved material with low molecular weight alcohol and stir it into a homogenous slurry;

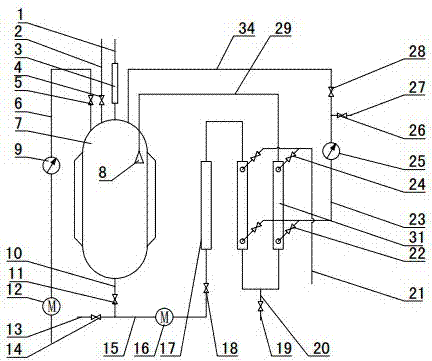

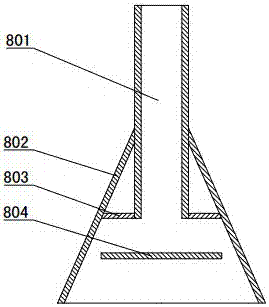

[0050] In the present embodiment, low-molecular alcohol is methanol, and the material after screening, i.e. turmeric powder, is dropped into the batching tank, and then methanol is dropped into the batching tank, and the mass ratio of turmeric powder to methanol is 1:3. Then stir the material in the batching tank into a homogenous slurry. Raise the temperature of the homogenate in the batching tank to 60°C, and then transport the homogenate to a ceramic membrane extraction device for extraction.

[0051] (3) Afte...

Embodiment 2

[0079] (1) Grinding the dry turmeric material and passing through a 100-mesh sieve;

[0080] The turmeric dry material is ultrafinely crushed and sieved through a 100-mesh sieve, wherein the water content of the turmeric dry material is less than or equal to 8%, so as to avoid excessive water content from hindering the extraction of saponins.

[0081] (2) Mix the sieved material with low molecular weight alcohol and stir it into a homogenous slurry;

[0082] In the present embodiment, the low-molecular alcohol is ethanol, and the material after sieving, i.e. turmeric powder, is dropped into the batching tank, and then into ethanol in the batching tank, the mass ratio of turmeric powder and ethanol is 1:2, Then stir the material in the batching tank into a homogenous slurry. Raise the temperature of the homogenate in the batching tank to 60°C, and then transport the homogenate to a ceramic membrane extraction device for extraction.

[0083] (3) After the homogenate is heated ...

Embodiment 3

[0096] (1) Grinding the dry turmeric material and passing through a 100-mesh sieve;

[0097] The turmeric dry material is ultrafinely crushed and sieved through a 100-mesh sieve, wherein the water content of the turmeric dry material is less than or equal to 8%, so as to avoid excessive water content from hindering the extraction of saponins.

[0098] (2) Mix the sieved material with low molecular weight alcohol and stir it into a homogenous slurry;

[0099] In the present embodiment, the low-molecular-weight alcohol is methanol, and the material after screening, i.e. turmeric powder, is dropped into the batching tank, and then methanol is dropped into the batching tank. The mass ratio of turmeric powder and methanol is 1:5. Then stir the material in the batching tank into a homogenous slurry. Raise the temperature of the homogenate in the batching tank to 60°C, and then transport the homogenate to a ceramic membrane extraction device for extraction.

[0100] (3) After the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com