Preparation method of vehicle urea

A technology for urea and urea for vehicles is applied in separation methods, preparation of urea derivatives, chemical instruments and methods, etc., which can solve the problems of complicated and complicated preparation processes and high production costs, reduce environmental pollution, high yield and save production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

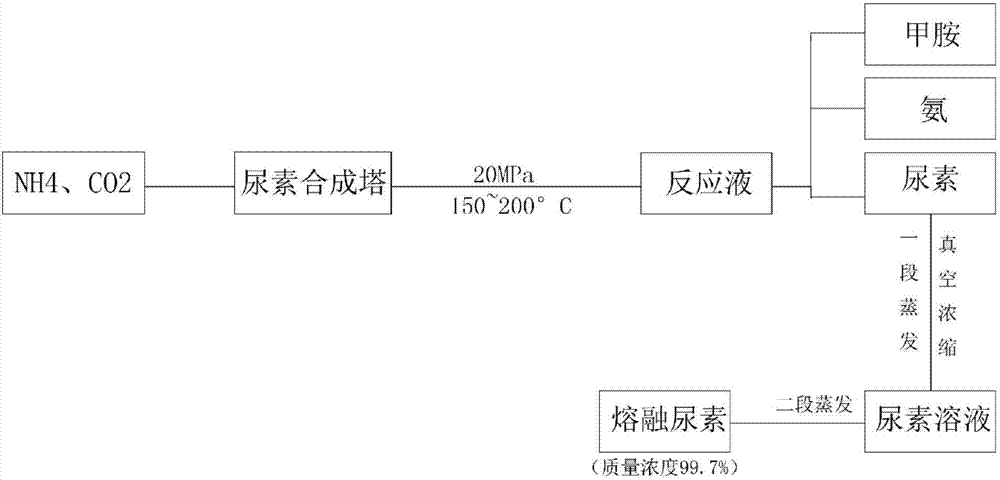

[0036] A method for preparing urea for vehicles, such as Figure 1~3 shown, including the following steps,

[0037] S1: Synthesize ammonia and carbon dioxide to obtain molten urea with a mass concentration of 80% and a mass percentage of diuresis less than or equal to 0.25%;

[0038] S2: pass the desalted water through the purified water equipment to obtain purified water with a resistivity of 18-20MΩ·cm;

[0039] S3: Add the molten urea in S1 and the purified water in S2 into the batching tank at the same time at a ratio of 1:1.5, and stir for more than 30 minutes to obtain a urea solution with a mass concentration of 31.5% to 32%;

[0040] S4: By fine-tuning the amount of the above-mentioned molten urea or purified water, a urea solution with a mass concentration of 32.5% is obtained, and the urea solution with this mass concentration is crude urea;

[0041] S5: obtaining urea for vehicles by filtering the crude urea;

[0042] S6: transporting the vehicle urea to the fini...

specific Embodiment approach

[0043] Specific implementation method: S1: use the intermediate product molten urea of the urea production plant as raw material to prepare molten urea, the specific steps of preparing molten urea, S11: send the raw material ammonia and carbon dioxide into the urea synthesis tower in a ratio of 4:1, and React at 20MPa and 180°C to obtain a reaction solution;

[0044] S12: The reaction liquid contains urea, methylamine, and excess ammonia, wherein the methylamine in the reaction liquid is decomposed and recovered by air stripping, and the ammonia is recycled through a recovery device. Finally, the reaction liquid is pre-concentrated in a vacuum and separated by one-stage evaporation to obtain a mass concentration It is 80%, 130°C, and the mass percentage of diuresis is equal to 0.25% of molten urea; the molten urea is placed in the urea solution tank, and the urea solution tank is connected with a urea solution pump, and the molten urea is transported to the batching tank thro...

Embodiment 2

[0054] Specific implementation method: S1: use the intermediate product molten urea of the urea production plant as raw material to prepare molten urea, the specific steps of preparing molten urea, S11: send the raw material ammonia and carbon dioxide into the urea synthesis tower in a ratio of 4:1, and React at 20MPa and 200°C to obtain a reaction solution;

[0055] S12: The reaction liquid contains urea, methylamine, and excess ammonia, wherein the methylamine in the reaction liquid is decomposed and recovered by air stripping, and the ammonia is recycled through a recovery device. Finally, the reaction liquid is pre-concentrated in a vacuum and separated by one-stage evaporation to obtain a mass concentration It is 80%, 130°C, and the mass percentage of diuresis is equal to 0.25% of molten urea; the molten urea is placed in the urea solution tank, and the urea solution tank is connected with a urea solution pump, and the molten urea is transported to the batching tank thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com