Aluminum alloy welding wire for automobile fuel tank and preparation method of aluminum alloy welding wire

A technology of aluminum alloy welding wire and automobile fuel tank, which is applied in the direction of welding equipment, metal processing equipment, welding medium, etc., and can solve the problems of damage to the weld, impact resistance of the weld of the fuel tank, low fatigue resistance, oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

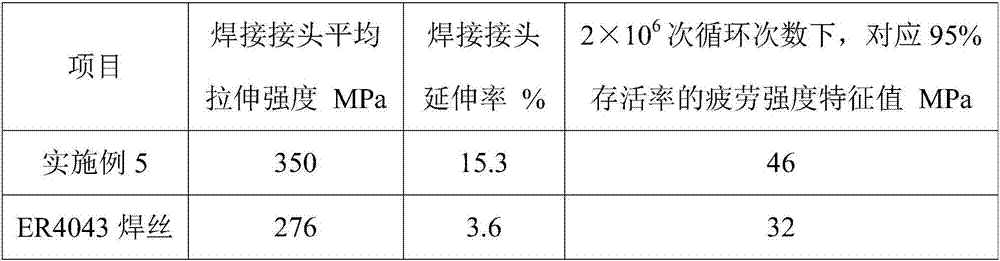

Examples

Embodiment 1

[0015] An aluminum alloy welding wire for an automobile fuel tank, the raw materials of which include by weight percentage: Mg: 6.5%, Mn: 0.65%, Ti: 0.17%, Be: 0.003%, Fe: 0.3%, B: 0.045%, Cr: 0.235% , Si: 0.35%, Zr: 0.2%, V: 0.175%, Sc: 0.25%, Cu≤0.1%, Zn≤0.2%, individual content of other impurity elements≤0.05%, total content of other impurity elements≤0.1%, and other The amount is Al.

[0016] The above-mentioned method for preparing aluminum alloy welding wire for automobile fuel tanks comprises the following steps: melting the aluminum ingot, adding the remaining raw materials for smelting, refining, and casting to obtain a round ingot satisfying the above-mentioned composition range; homogenizing, extruding, and Annealing and drawing treatment are used to obtain aluminum alloy welding wire for automobile fuel tanks.

Embodiment 2

[0018] An aluminum alloy welding wire for an automobile fuel tank, the raw materials of which include by weight percentage: Mg: 6.3%, Mn: 0.8%, Ti: 0.16%, Be: 0.005%, Fe: 0.2%, B: 0.08%, Cr: 0.22% , Si: 0.4%, Zr: 0.16%, V: 0.2%, Sc: 0.2%, Cu≤0.1%, Zn≤0.2%, the single content of other impurity elements≤0.05%, the total content of other impurity elements≤0.1%, the rest The amount is Al.

[0019] The above-mentioned method for preparing aluminum alloy welding wire for automobile fuel tanks comprises the following steps: melting the aluminum ingot, adding the remaining raw materials for smelting, refining, and casting to obtain a round ingot satisfying the above-mentioned composition range; homogenizing, extruding, and The aluminum alloy welding wire for automobile fuel tank was obtained by annealing and drawing. The homogenization temperature was 475°C, the homogenization temperature was 24h, the extrusion temperature was 440°C, the extrusion ratio was 40, the annealing temperatu...

Embodiment 3

[0021] An aluminum alloy welding wire for an automobile fuel tank, the raw materials of which include by weight percentage: Mg: 6.7%, Mn: 0.5%, Ti: 0.18%, Be: 0.0001%, Fe: 0.4%, B: 0.01%, Cr: 0.25% , Si: 0.3%, Zr: 0.25%, V: 0.15%, Sc: 0.3%, Cu≤0.1%, Zn≤0.2%, the single content of other impurity elements≤0.05%, the total content of other impurity elements≤0.1%, the rest The amount is Al.

[0022] The above-mentioned method for preparing aluminum alloy welding wire for automobile fuel tanks comprises the following steps: melting the aluminum ingot, adding the remaining raw materials for smelting, refining, and casting to obtain a round ingot satisfying the above-mentioned composition range; homogenizing, extruding, and The aluminum alloy welding wire for automobile fuel tank was obtained by annealing and drawing. The homogenization temperature was 455°C, the homogenization temperature was 36h, the extrusion temperature was 430°C, the extrusion ratio was 45, the annealing tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com