Catalyst for removing nitric oxide in flue gas under low temperature, and preparation method and application thereof

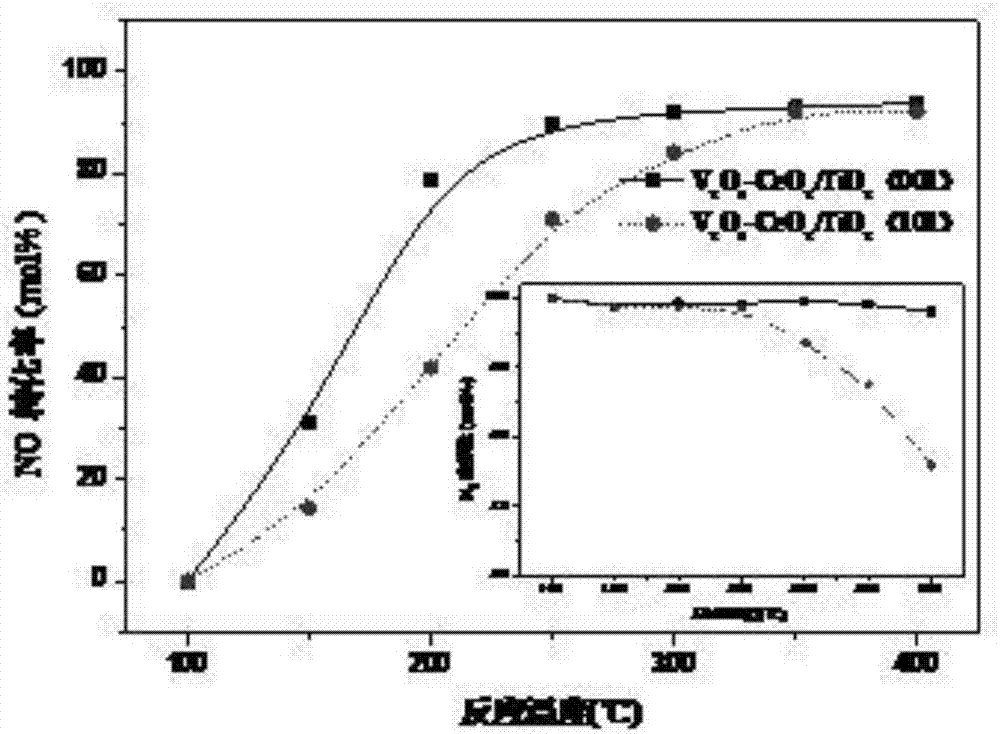

A technology of nitrogen oxides and catalysts, which is applied to catalysts for removing nitrogen oxides in flue gas at low temperature and its preparation method and application field. application and other issues, to achieve the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Anatase TiO with Preferentially Exposed (001) Facets 2 The carrier is prepared by HF-hydrothermal method. Add 20mL tetrabutyl titanate Ti(OC 4 h 9 ) 4 , 3.2 mL of 40 wt.% HF was slowly added dropwise with stirring at room temperature. Then hydrothermal treatment at 200 °C for 24 h, and white TiO was collected after cooling 2 Precipitation, the precipitate was repeatedly washed and filtered with deionized water and ethanol, and then dried at 110°C.

[0023] Weigh a certain amount of cerium nitrate Ce(NO 3 ) 2 ·6H 2 O (Sinopharm Group Chemical Reagent Co., Ltd. A.R.) was dissolved in deionized water to prepare a 0.1moVL cerium nitrate solution. Weigh a certain amount of the above TiO 2 In a small beaker beaker, according to the required load, measure a certain amount of cerium nitrate solution in the beaker, ultrasonic for 10 seconds, put it in an oven at 80°C and evaporate until the immersion night is just covered with TiO 2 On the surface of the powder, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com