Nattokinase composition and preparation method thereof

The technology of nattokinase and composition is applied in the field of nattokinase composition and its preparation, which can solve the problems of lack of effective substances of nattokinase, low activity of nattokinase, etc., and achieve the effect of preventing thrombolysis, inhibiting platelet aggregation, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0033] The preparation method of nattokinase composition comprises the following steps:

[0034] (1) Put nattokinase, β-cyclodextrin, citric acid, and xylitol into the boiling granulator according to the ratio of raw materials in Table 1, and open the boiling granulator to fully prepare various raw and auxiliary materials in the boiling granulator. Mix for 8 minutes, then use water as the wetting agent for spray granulation, control the air inlet temperature to 85°C, and the outlet air temperature to 45°C, stop spraying and dry for 1 hour, and the moisture content of the particles is 3wt%;

[0035] (2) The prepared granules are sized with a 30-mesh sieve by a granulator.

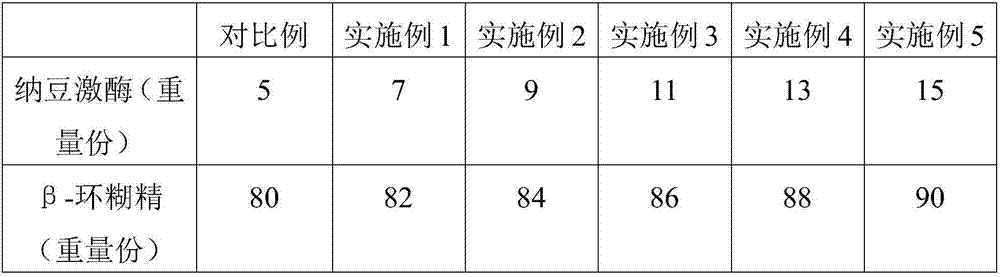

[0036] Table 1: Raw material ratio and performance test results table of nattokinase composition

[0037]

[0038]

[0039] Find out by table 1, adopt the raw material proportioning of embodiment 2, embodiment 3, i.e. nattokinase is 9-11 weight part, and β-cyclodextrin is 84-86 weight part, and citric...

Embodiment 6-10

[0041] The preparation method of nattokinase composition comprises the following steps:

[0042] (1) Put nattokinase, β-cyclodextrin, citric acid, xylitol into the boiling granulator according to the raw material ratio of Table 2, open the boiling granulator and put various raw and auxiliary materials in the boiling granulator fully Mix for 8 minutes, then use water as the wetting agent for spray granulation, control the air inlet temperature to 85°C, and the outlet air temperature to 45°C, stop spraying and dry for 1 hour, and the moisture content of the particles is 3wt%;

[0043] (2) The prepared granules are sized with a 30-mesh sieve by a granulator.

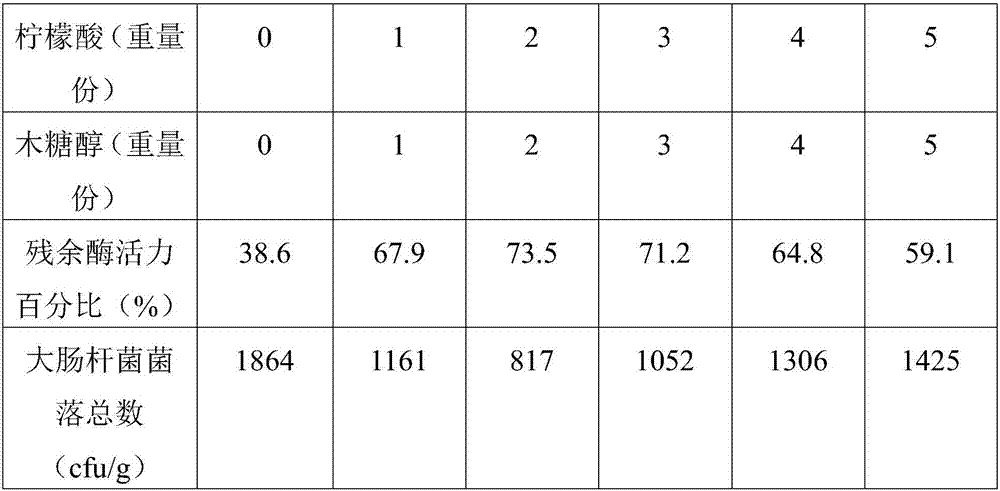

[0044] Table 2: Raw material ratio and performance test results of nattokinase composition

[0045]

[0046]

[0047] Find out from Table 2, adopt the raw material ratio of embodiment 8, namely the performance of nattokinase composition is comparatively ideal when citric acid is 2.5 weight parts.

Embodiment 11-15

[0049] The preparation method of nattokinase composition comprises the following steps:

[0050] (1) Put nattokinase, β-cyclodextrin, citric acid, xylitol into the boiling granulator according to the raw material ratio of Table 3, open the boiling granulator and put various raw and auxiliary materials in the boiling granulator fully Mix for 8 minutes, then use water as the wetting agent for spray granulation, control the air inlet temperature to 85°C, and the outlet air temperature to 45°C, stop spraying and dry for 1 hour, and the moisture content of the particles is 3wt%;

[0051] (2) The prepared granules are sized with a 30-mesh sieve by a granulator.

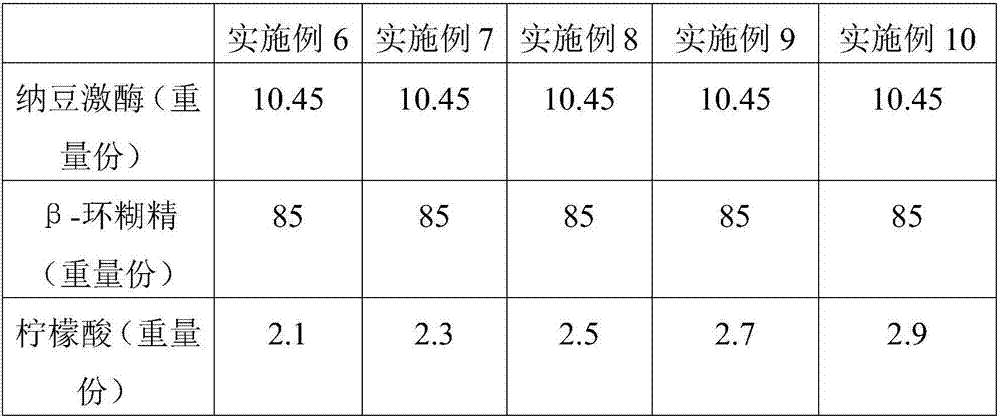

[0052] Table 3: Raw material ratio and performance test results of nattokinase composition

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com