Surface-modified amphiphilic anisotropic powder, emulsion composition containing same, and method for preparing same

An emulsion composition, anisotropic technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of impractical application, geometric restrictions, and difficulties in uniform mass production, and achieve a yield suitable for, The effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0085] Preparation Example 1 - Preparation of Polystyrene (PS) First Polymer Spheres

[0086] Styrene (as a monomer), sodium 4-vinylbenzenesulfonate (as a stabilizer), and azobisisobutyronitrile (AIBN) (as an initiator) The liquid phase was mixed and allowed to react at 75°C for 8 hours. The reaction was carried out by stirring the reaction mixture at a speed of 200 rpm in a cylindrical reactor with a diameter of 11 cm (centimeter) and a height of 17 cm (centimeter) made of glass.

preparation Embodiment 2

[0087] Preparation Example 2 - Preparation of coated first polymer spheres with core-shell (CS) structure

[0088] The polystyrene (PS) first polymer spherical particles obtained as previously described are mixed styrene (as a monomer), 3-(trimethoxysilyl) propyl acrylate (3-(trimethoxysilyl) propyl acrylate) (TMSPA) and azobisisobutyronitrile (AIBN) as initiators, and the reaction mixture was allowed to react. The reaction is carried out by stirring the reaction mixture in a cylindrical reactor.

preparation Embodiment 3

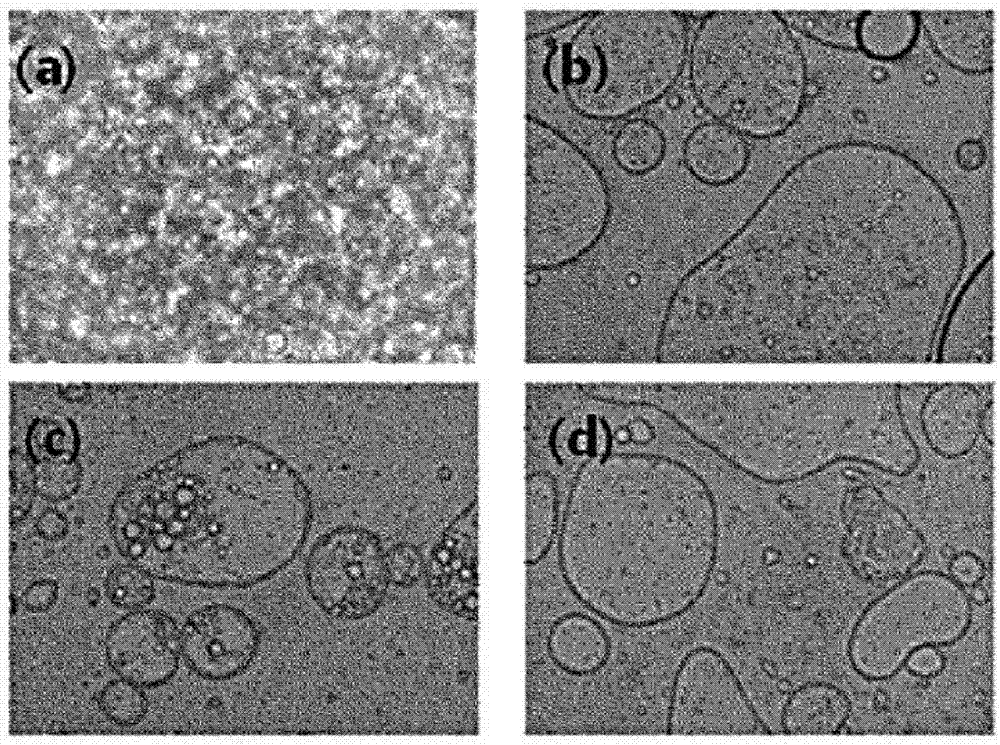

[0089] Preparation Example 3 - Preparation of Anisotropic Powder

[0090] Aqueous dispersions of polystyrene core-shell (PC-CS) dispersions obtained as previously described were mixed with styrene (as monomer), sodium 4-vinylbenzene sulfonate (as stabilizer) , and azobisisobutyronitrile (AIBN) (as an initiator), and the reaction mixture is heated to 75°C for reaction. The reaction is carried out by stirring the reaction mixture in a cylindrical reactor. In this way, an anisotropic powder is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com