Light-weight aviation interior composite film

A composite membrane and aviation technology, applied in the field of composite membrane materials, can solve the problems of lack of reinforcements, mechanical properties that cannot be adapted to exposure, and insufficient adhesion, and achieve excellent weather resistance, make up for lack of mechanical strength, and save fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

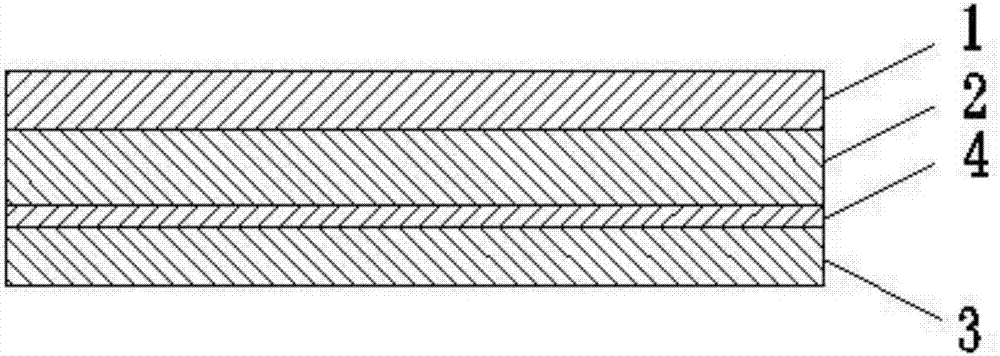

[0019] Such as figure 1 As shown, a lightweight aviation interior composite film according to the present invention has a fluorine-containing coating 1 as a surface layer, a PET aluminized film or a PI aluminized film as a matrix layer 2, and a fiber fabric 3 as a reinforcement , three layers are sequentially compounded; the surface of the base layer in contact with the fiber fabric is provided with an aluminum-plated surface 4, and the fiber fabric 3 is laid on the aluminum-plated surface 4 in a grid shape, and the fluorine-containing coating 1 is made of fluorine-containing The paint is directly coated on the surface of the base layer 2 to form.

[0020] The fluorine-containing coating 1 is obtained by polymerizing a fluorine-containing precursor and a polymer monomer. The fluorine-containing precursor can be selected from short straight-chain perfluoroalkyl groups, branched-chain pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com