Sulfur-tolerant methanation catalyst and preparation method thereof as well as magnesium aluminate spinel composite carrier and preparation method thereof

A magnesium-aluminum spinel, sulfur-resistant methanation technology, applied in the direction of catalyst carrier, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of affecting catalyst high temperature stability and catalyst life Shortening, use performance and production cost can not be achieved, to achieve the effect of improving reaction stability and high temperature catalytic performance stability, improving reaction stability and high temperature catalytic performance stability, improving CO conversion rate and methane selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a preparation method of the above-mentioned sulfur-resistant methanation catalyst, comprising:

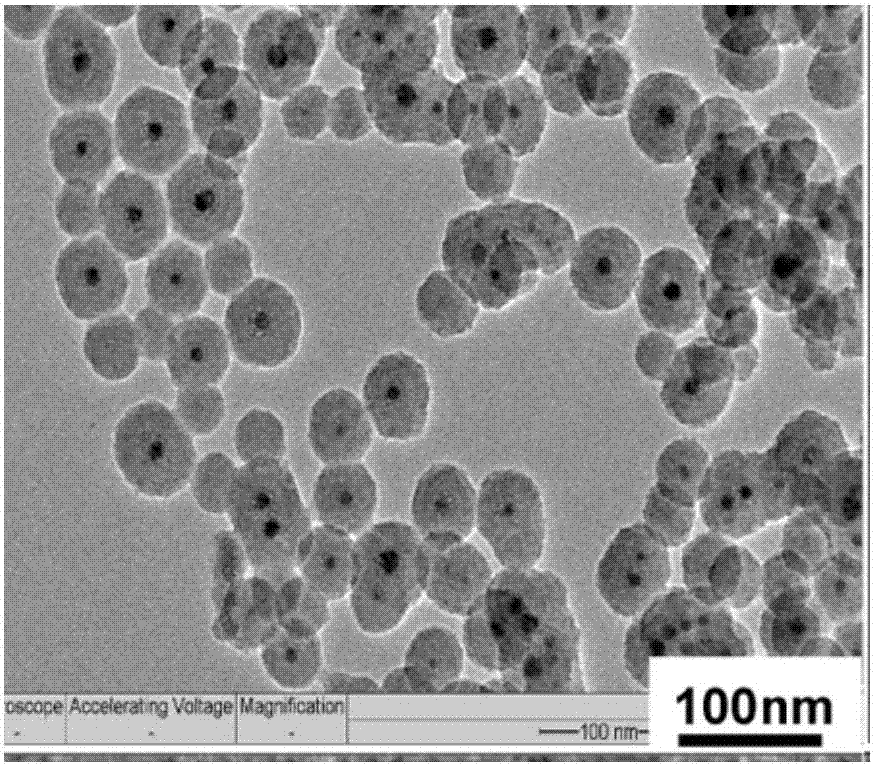

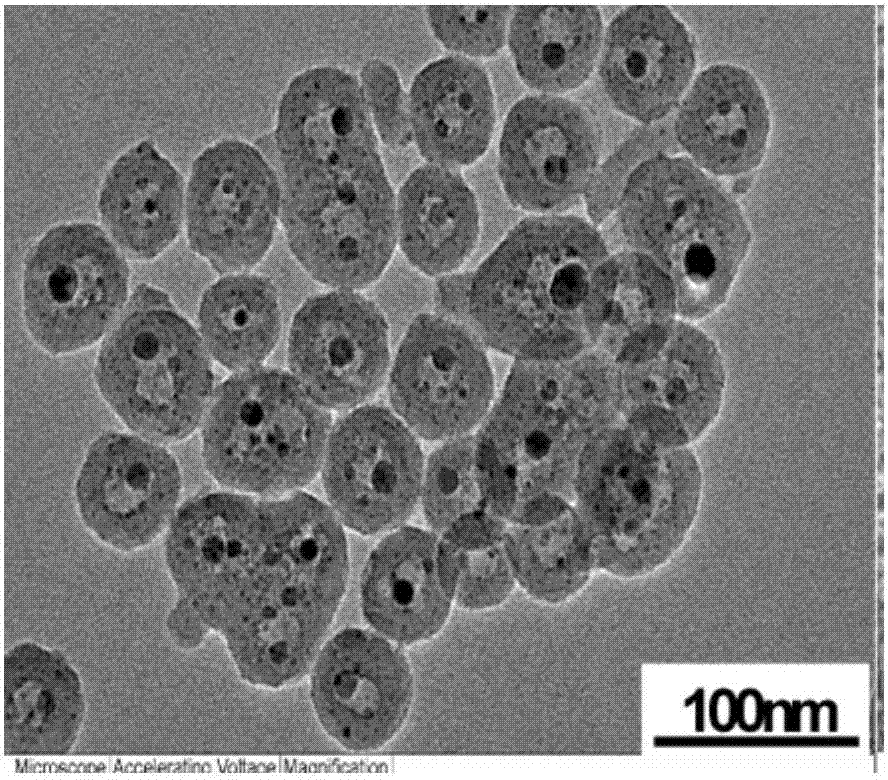

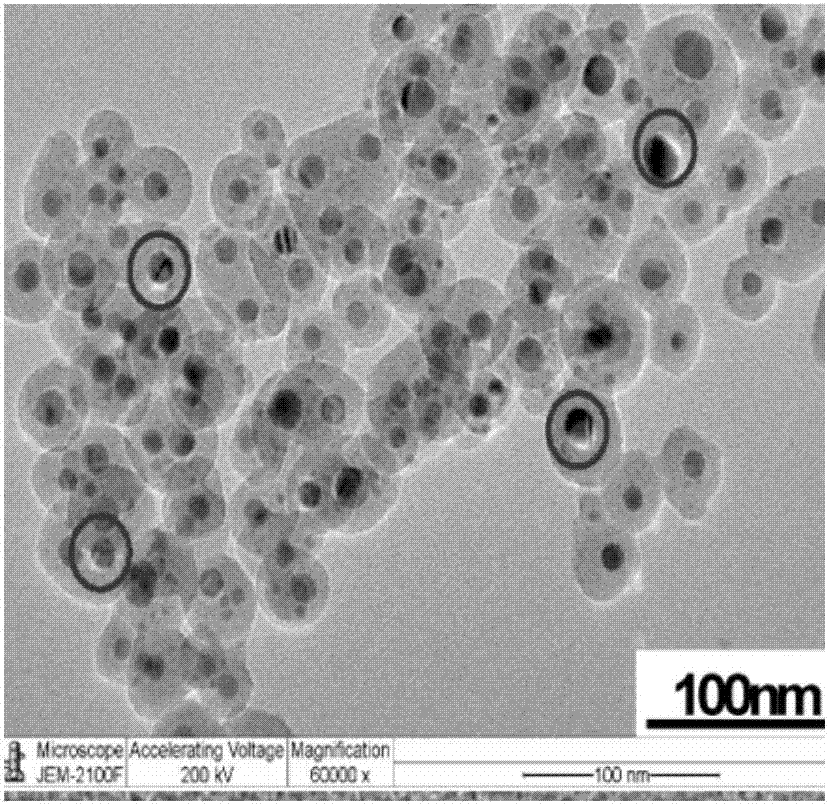

[0038] (1) providing magnesium aluminum spinel, and using the solution of carrier modifier precursor and magnesium aluminum spinel to prepare the magnesium aluminum spinel composite carrier of core-shell structure;

[0039] (2) Loading the solution of the precursor of the catalyst active component and the solution of the precursor of the optional catalyst promoter onto the magnesium-aluminum spinel composite carrier of the core-shell structure;

[0040] (3) Drying and roasting the product of step (2).

[0041] In the present invention, there is no particular limitation on the source of the magnesium aluminum spinel, which can be prepared by itself or purchased commercially. Therefore, the method for preparing a sulfur-tolerant methanation catalyst of the present invention may also include the step of preparing magnesium aluminum spinel. There...

Embodiment 1

[0077] This example is used to illustrate the preparation of magnesium-aluminum-spinel composite carrier and sulfur-resistant methanation catalyst by co-precipitation-microwave method.

[0078] (1) Preparation of 83Al by co-precipitation method 2 o 3 / 17MgO aluminum magnesium spinel porous carrier

[0079] 311.4g of Al(NO 3 ) 3 9H 2 O and 64.2g of Mg(NO 3 ) 3 ·6H 2 O is jointly dissolved in 500 milliliters of deionized water to form a mixed solution, and the mixed solution and concentrated ammonia water diluted five times (concentration of strong ammonia water is 25wt%) are added into the beaker in parallel at 80° C. and 600 rpm under stirring, and the pH value is maintained at 11.5. After reacting until the precipitation is complete, let stand and age for 12 hours, filter to obtain the precipitate, and wash it with deionized water three times. Put the obtained filter cake in an oven at 120°C for 12 hours to obtain a dry powder. The above dry powder was calcined in a m...

Embodiment 2

[0086] This example is used to illustrate the preparation of magnesium-aluminum-spinel composite carrier and sulfur-resistant methanation catalyst by kneading-microwave method.

[0087] (1) Preparation of 83Al by kneading method 2 o 3 / 17MgO aluminum magnesium spinel porous carrier

[0088] Weigh 300g pseudo-boehmite (Al 2 o 3 content is 70% by weight) is put into the kneader, and the Mg (NO 3 ) 3 ·6H 2 0 and 90 milliliters of deionized water, after mixing evenly, add 12.5g of acidic peptizer nitric acid, make the mixture carry out peptization, then knead for 2h, the mixture shows good plasticity, then the mixture is packed into extruded bars with cylindrical orifices Formed in the machine, the mixture is extruded into a wet bar. After drying the wet strip at 120°C, it was calcined at 700°C for 5 hours in an air atmosphere to obtain a columnar aluminum-magnesium spinel porous carrier, which was analyzed by X-ray fluorescence spectrometer (XRF). The composition of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com