Capillary column resistant to protein adsorption and preparation method thereof

An anti-protein adsorption and capillary column technology, which is applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problem of high toxicity in the production process and poor quality of anti-protein adsorption capillary electrophoresis covalently bonded coating columns Excellent, complex preparation process, etc., to achieve excellent anti-protein adsorption ability, excellent anti-protein adsorption performance, simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a capillary column resistant to protein adsorption, comprising the steps of:

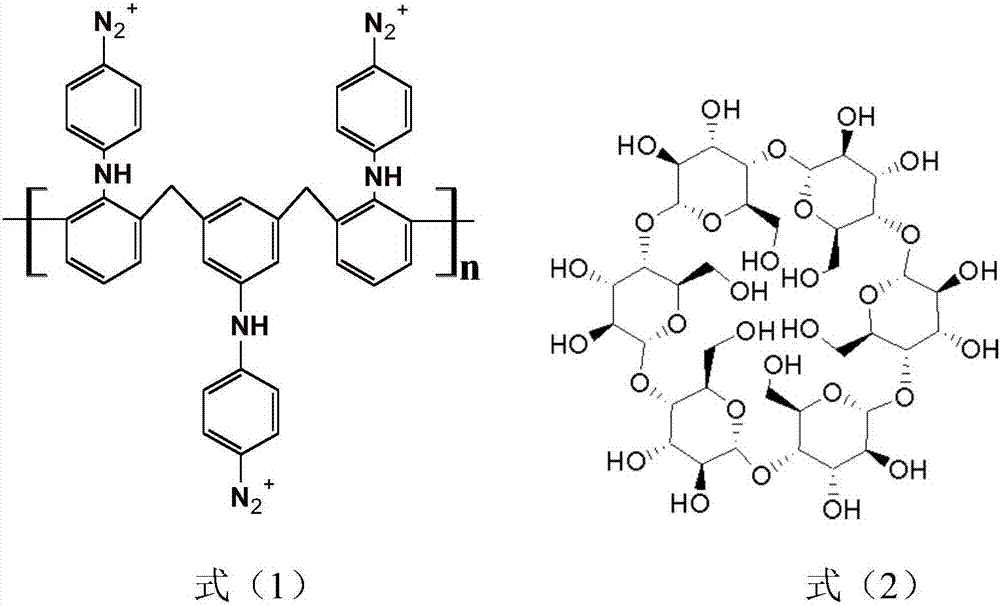

[0029] S1, the concentration is 2-6mg·ml -1 Photosensitive diazo resin solution, water, concentration 2-6mg·ml -1 The cyclodextrin aqueous solution and water are slowly injected into the activated capillary successively; the mass ratio of the photosensitive diazo resin to the cyclodextrin is 1:(1-1.3);

[0030] S2. Dry the capillary prepared in step S1, and expose it to an ultraviolet lamp with a wavelength of 248nm-365nm for 10min-30min to construct a protein-adsorption-resistant capillary column with a diazo resin-cyclodextrin composite structure.

[0031] The weight-average molecular weight Mw of the photosensitive diazo resin is 700-5500, and the weight-average molecular weight of the diazo resin is too small, and the degree of crosslinking is not good enough to affect the coating effect; when the weight-average molecular weight is too large, the solubility of the...

Embodiment 1

[0043] This implementation provides a kind of preparation method of the anti-protein adsorption capillary column, comprises the following steps:

[0044] S0, capillary internal activation pretreatment

[0045] successively with a concentration of 0.1mol·L -1 Sodium hydroxide solution, distilled water, the concentration is 0.1mol L -1 Flush the capillary with hydrochloric acid solution, distilled water and methanol for 30min, 10min, 30min, 10min and 10min respectively, and then use N 2 The activated capillary can be obtained by drying the capillary.

[0046] S1. At a temperature of 10°C, use a concentration of 2mg·ml - The photosensitive diazo resin solution (Mw=2500) washes the capillary column for 10 minutes, and the distilled water washes the capillary column for 2 minutes. Then use a concentration of 2mg·ml -1 The cyclodextrin aqueous solution washes the capillary column for 10 minutes, and then washes the capillary column with distilled water for 1 minute, so that an ...

Embodiment 2

[0052] This implementation provides a kind of preparation method of the anti-protein adsorption capillary column, comprises the following steps:

[0053] S0, capillary internal activation pretreatment

[0054] successively with a concentration of 0.09mol·L -1 Sodium hydroxide solution, distilled water, the concentration is 0.11mol L -1 Flush the capillary with hydrochloric acid solution, distilled water and methanol for 35min, 8min, 35min, 8min and 8min respectively, and then use N 2 The activated capillary can be obtained by drying the capillary.

[0055] S1. At a temperature of 20°C, use a concentration of 3mg·ml - The photosensitive diazo resin solution (Mw=750) was used to wash the capillary column for 10 minutes, and the distilled water was used to wash the capillary column for 2 minutes. Then use a concentration of 2mg·ml -1 The cyclodextrin aqueous solution washes the capillary column for 10 minutes, and then washes the capillary column with distilled water for 1 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com