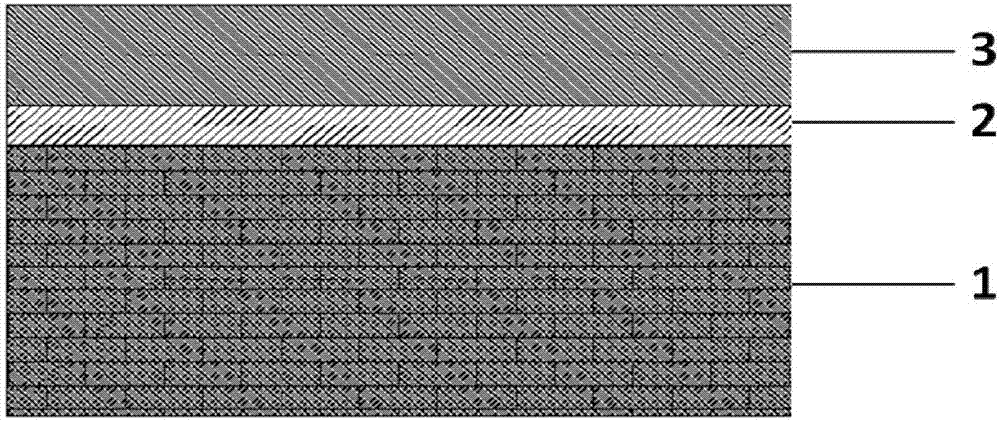

Transparent electrode based on ultra-thin metallic film and preparation method and application thereof

A technology of transparent electrodes and ultra-thin metals, applied in the field of electrodes, can solve problems such as affecting compatibility, increasing costs, and poor mechanical flexibility of ITO, achieving the effects of improving optical performance, increasing aperture ratio, and increasing degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

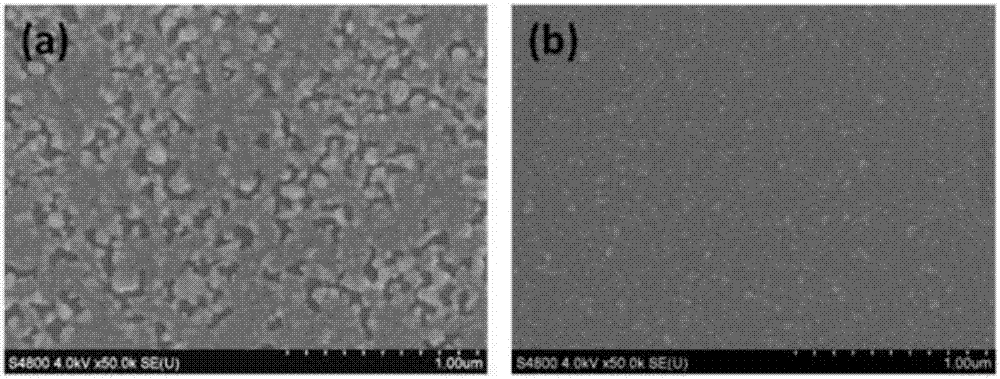

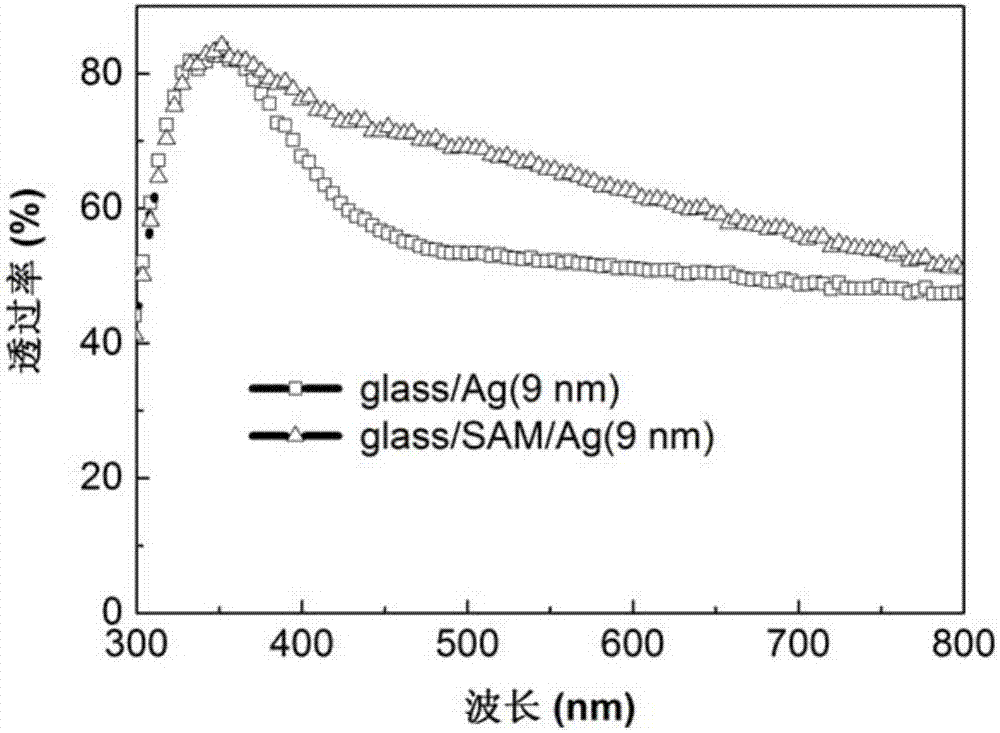

[0040] (1) Ultra-clear glass with a thickness of 1mm was used as a transparent substrate, and the glass was ultrasonically cleaned with acetone, ethanol, and deionized water, and dried with N 2 Blow dry, and then treat the glass surface with ultraviolet ozone for 20 minutes, then put it into the magnetron sputtering chamber immediately, and start vacuuming.

[0041] (2) Wait until the vacuum degree of the magnetron sputtering chamber reaches 5×10 -4 Below Pa, feed 40sccm high-purity argon as the deposition gas. A DC sputtering metal Ag target was used, the DC sputtering power was 20W, and the sputtering time was controlled to obtain a 9nm thick Ag film. After the film deposition was completed, the sample was taken out to obtain a glass / Ag (9nm) sample. During the preparation process, the substrate temperature was room temperature, and the substrate was kept rotating to ensure the uniformity of the film.

[0042] (3) Deposit 30nm TiO on the Ag layer plated in step (2) 2 film...

Embodiment 2

[0046] (1) Ultra-clear glass with a thickness of 1mm was used as a transparent substrate, and the glass was ultrasonically cleaned with acetone, ethanol, and deionized water, and dried with N 2 Blow dry, and then treat the glass surface with ultraviolet ozone for 20 minutes.

[0047] (2) Prepare a self-assembly solution, the components of which are isopropanol, deionized water and 3-aminopropyltrimethoxysilane, with a volume ratio of 18:1:1. Immerse the glass cleaned in step (1) in the self-assembly solution for 2 hours. Rinse with isopropanol and rinse with N 2 Dry it, then put it into the magnetron sputtering chamber immediately, and start vacuuming.

[0048] (3) Wait until the vacuum degree of the magnetron sputtering chamber reaches 5×10 -4 Below Pa, feed 40sccm high-purity argon as the deposition gas. A metal Ag target was sputtered by direct current, the direct current sputtering power was 20W, and the sputtering time was controlled to obtain a 9nm thick Ag film. Af...

Embodiment 3

[0056] (1) Ultra-clear glass with a thickness of 1mm was used as a transparent substrate, and the glass was ultrasonically cleaned with acetone, ethanol, and deionized water, and dried with N 2 Dry it, then put it into the magnetron sputtering chamber immediately, and start vacuuming.

[0057] (2) Wait until the vacuum degree of the magnetron sputtering chamber reaches 5×10 -4 Below Pa, feed 40sccm high-purity argon as the deposition gas. A DC sputtering metal Ag target was used, the DC sputtering power was 20W, and the sputtering time was controlled to obtain a 6nm thick Ag film. After the film deposition was completed, the sample was taken out to obtain a glass / Ag (6nm) sample. During the preparation process, the substrate temperature was room temperature, and the substrate was kept rotating to ensure the uniformity of the film. The above Ag film deposition rates have been determined by ellipsometer measurements.

[0058] (3) Depositing a 40nm AZO thin film on the Ag laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com