Detecting and absorbing device applied to sulfur hexafluoride gas

A technology of sulfur hexafluoride gas and absorption device, which is applied in the direction of measuring device, gas treatment, preparation of test samples, etc., can solve the problems that the absorption effect cannot be judged in real time, the deviation of the measurement result is large, and it is not easy to absorb completely, etc. Achieve the effects of improving measurement accuracy, increasing full contact absorption, and improving measurement accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

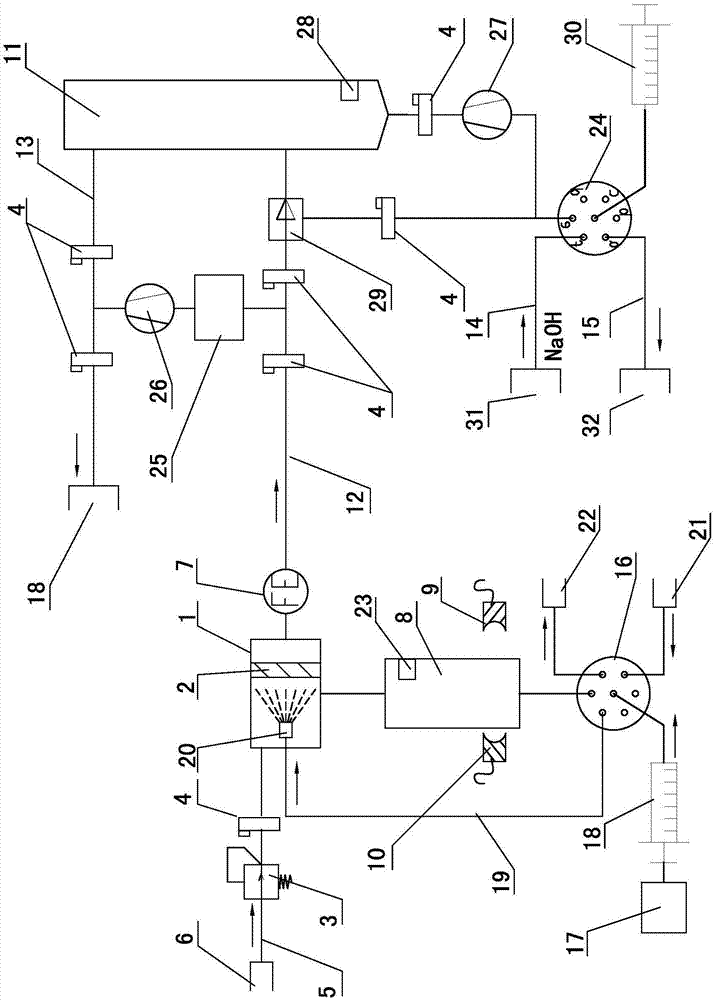

[0021] The technical solutions of the present invention will be further described below in conjunction with the embodiments. exist figure 1 In the example shown:

[0022] The airtight tank body 1 is provided with a filter membrane 2, the filter membrane 2 adopts a glass fiber membrane, the air inlet and the exhaust port of the airtight tank body 1 are located on both sides of the filter membrane 2, and the air inlet is provided with a solenoid valve 4 and Pipeline 5 of pressure stabilizing valve 3 communicates with SF 6 Air source 6, flow sensor 7 is arranged on the exhaust port, the SF entering the airtight tank body 1 6 The gas flow rate is controlled at 166mL / min, and the pressure is controlled at 0.5kPa. The top of the detection tank 8 communicates with the bottom of the airtight tank body 1 near the air inlet side, the liquid level control switch 23 is located on the side wall of the upper end of the detection tank 8, and the infrared light source 9 and the infrared de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com