High-temperature-resistance quantum dot fluorescent material and preparation method thereof

A technology of fluorescent materials and quantum dots, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a high-temperature-resistant quantum dot fluorescent material, comprising the following preparation steps:

[0034] S100, preparing Se solution;

[0035] S200. Synthesizing quantum dots:

[0036] S210, taking cadmium source, zinc source, fatty acid and organic solvent and placing them in a container;

[0037] S220, heating the mixture in S210 to 80°C-110°C, pumping air for 30min-40min, and then heating to 280°C-310°C;

[0038] S230. Add the Se solution, heat it for a period of time, and raise the temperature to 300°C-310°C;

[0039] S230, adding the Se solution again, keeping the temperature for 20 min to 40 min, and then cooling to room temperature to obtain the CdZnSe@ZnSe quantum dot stock solution;

[0040] S300, purifying the obtained CdZnSe@ZnSe quantum dot stock solution to obtain a high temperature resistant quantum dot fluorescent material.

[0041] Wherein, the Se solution is injected for the first time to form CdZnSe quantum dots, a...

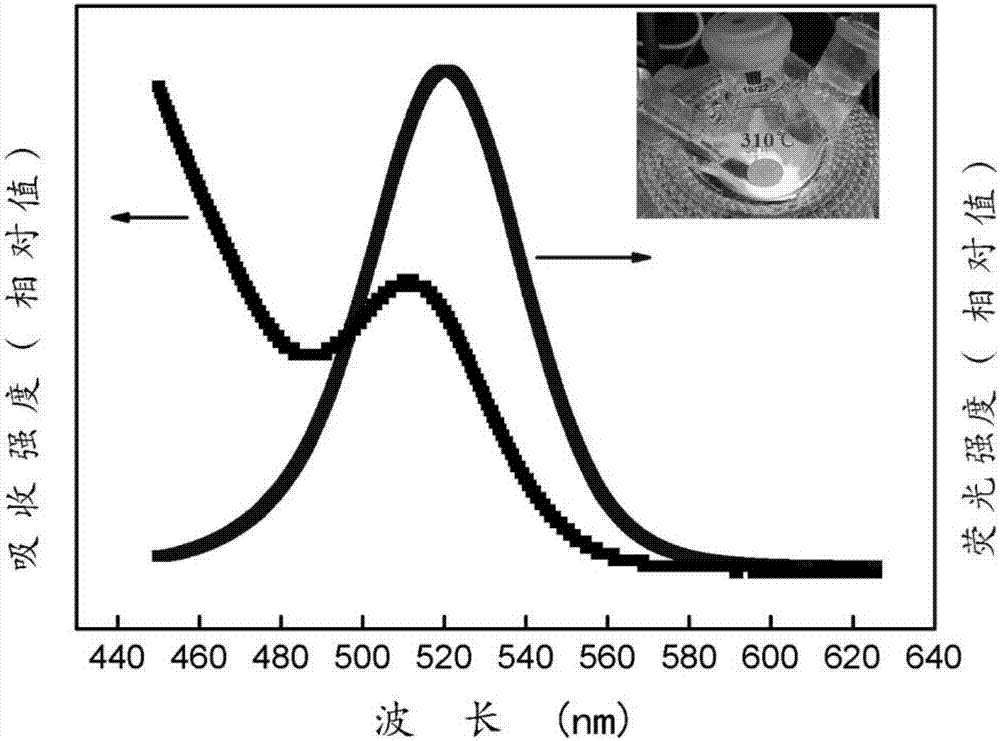

Embodiment 1

[0061] Preparation of quantum dot precursor solution (i.e. Se solution): take 1mmol selenium powder and place it in a centrifuge tube, add 2ml octadecene, shake evenly, and then sonicate for 10min to obtain precursor solution A; repeat the above operation once to obtain precursor solution A Same as Precursor B.

[0062] Synthesis of quantum dots: Take 0.25mmol cadmium oxide and 2.5mmol zinc acetate in a three-necked flask, then add 2ml oleic acid and 5ml octadecene, stir and heat to 100°C, and pump for 30min;

[0063] Further heat up to 280°C, quickly inject precursor solution A; keep warm for 10 minutes to obtain CdZnSe quantum dot core; continue to heat up to 300°C, add precursor solution B drop by drop, then raise the temperature to 310°C for 30 minutes and cool to room temperature to obtain CdZnSe@ZnSe Quantum dot stock solution.

[0064] Purification of quantum dots: Take 2ml of the CdZnSe@ZnSe quantum dot stock solution prepared above, add 2ml of n-hexane, shake evenly;...

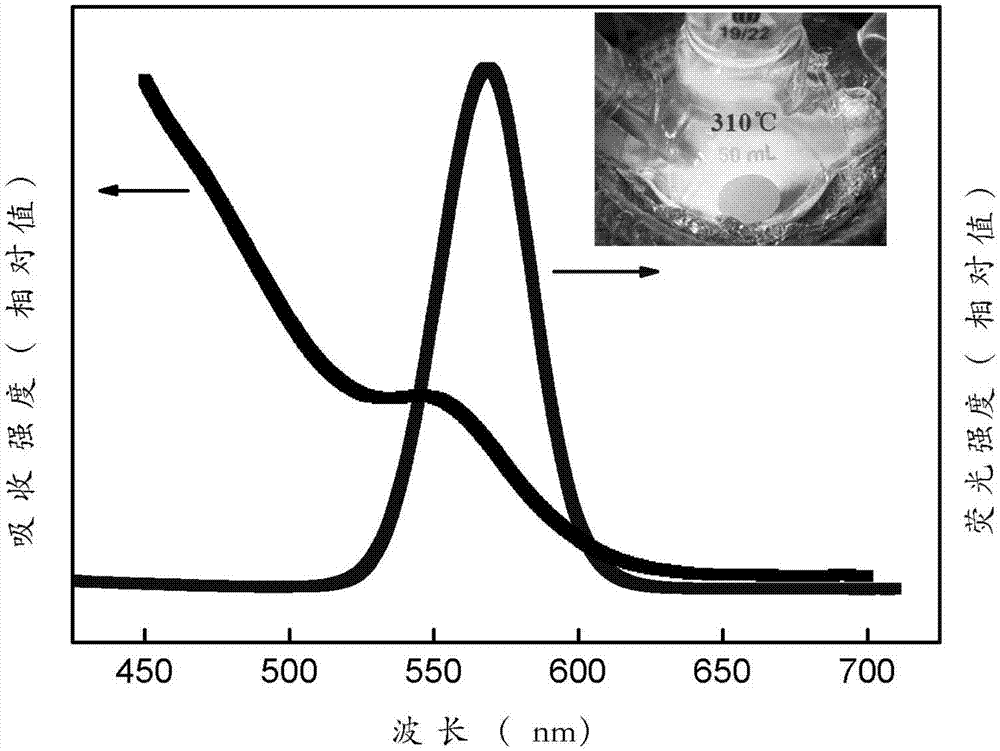

Embodiment 2

[0067] Prepare quantum dot precursor solution (i.e. Se solution): take 1mmol selenium powder and place it in a centrifuge tube, add 0.5ml trioctylphosphine and 1.5ml octadecene, oscillate evenly until the selenium powder is completely dissolved to obtain precursor solution A; repeat the above operation Once, get Precursor B which is the same as Precursor A.

[0068] Synthesis of quantum dots: Take 0.25 mmol of cadmium oxide and 2.5 mmol of zinc acetate in a three-necked flask, then add 2 ml of oleic acid and 5 ml of octadecene, stir and heat to 100 ° C, and pump for 30 min;

[0069] Further heat up to 290°C, quickly inject precursor solution A; keep warm for 10 minutes to obtain CdZnSe quantum dot core; continue to heat up to 310°C, add precursor solution B drop by drop, then heat up to 310°C for 30 minutes and cool to room temperature to obtain CdZnSe@ZnSe Quantum dot stock solution.

[0070] Purification of quantum dots: Take 2ml of CdZnSe@ZnSe quantum dot stock solution, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com