Antirust coating for steel facilities under oceanity condition and preparation method thereof

An anti-rust coating, marine technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems that the anti-corrosion coating does not have self-healing performance, cannot automatically repair ship corrosion, and achieve good atmospheric corrosion Corrosion inhibition, chemical solvent resistance, corrosion inhibitor stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

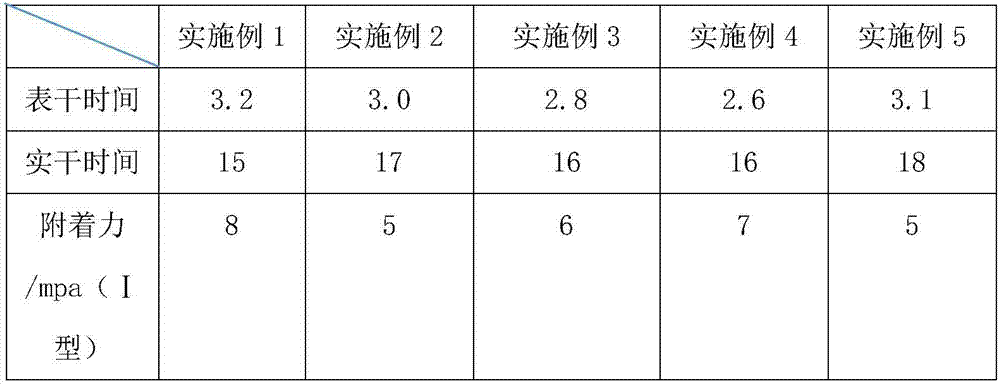

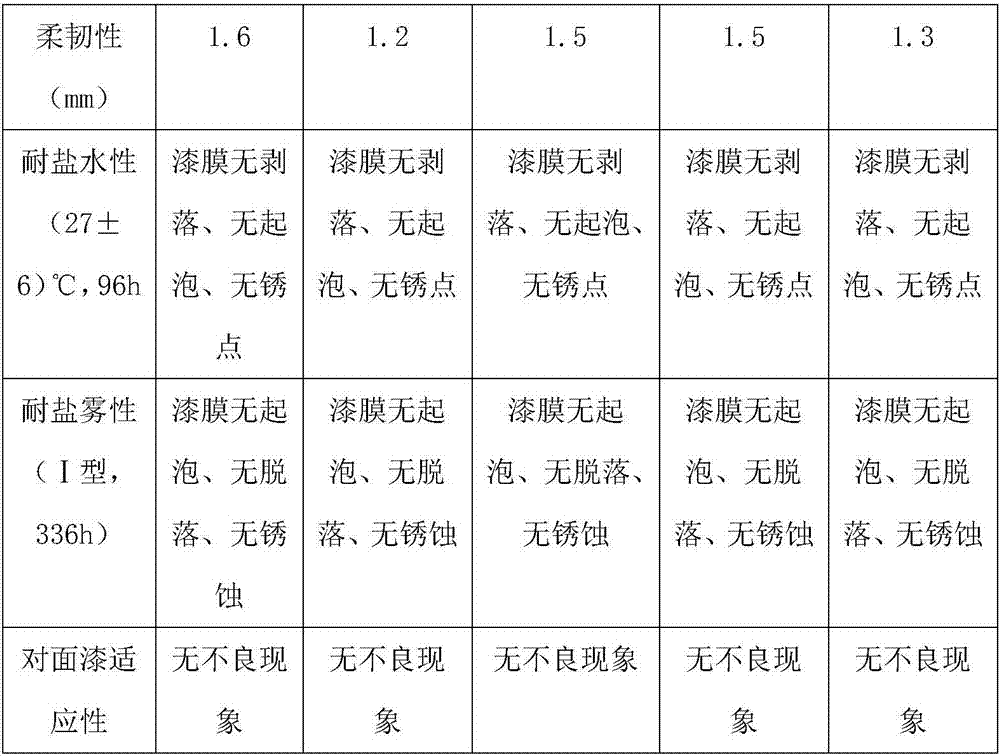

Examples

preparation example Construction

[0050] The synthetic method of diphenolic propane epoxy resin comprises the steps:

[0051] A. Add hydrogenated bisphenol A, epichlorohydrin, sodium hydroxide and toluene in sequence in the three-necked flask, heat and stir;

[0052] B. Add distilled water to remove alkali, and continue heating to 70°C;

[0053] c. Add aqueous sodium hydroxide solution and stir for 3 hours;

[0054] d. Wash the liquid separation with distilled water until the pH value of the separated water layer is neutral;

[0055] E. The filtrate is distilled at 100° C., and the tail gas in the condensation and deposition process is vented.

[0056] The preparation method of vapor phase corrosion inhibitor:

[0057] (1) configure the aqueous solution of propargylamine by formula quantity;

[0058] (2) Add dimethyl sulfoxide in the formula ratio to the aqueous solution of propargylamine and mix to obtain the gas phase corrosion inhibitor.

Embodiment 1

[0060] One, prepare gas-phase antirust coating according to the following raw material ratio:

[0061] Bisphenol A epoxy resin 28%

[0062] Vapor phase corrosion inhibitor (8% alkyne amine, 9% dimethyl sulfoxide and 83% water) 10%

[0064] Auxiliary 1%

[0065] Organic solvent 17% 2. Specific preparation method of vapor phase antirust coating:

[0066] (1) Epoxy resin and organic solvent are weighed according to the formula and put into the cylinder;

[0067] (2) Add gas-phase corrosion inhibitors and additives, and stir at low speed for 15 minutes with a high-speed disperser until the dispersion is uniform;

[0068] (3) Add pigments and fillers to the mixture in step (2), stir and disperse at high speed at 1200-1500r / min for 30 minutes, heat up to 55°C, and keep warm for 15 minutes;

[0069] (4) Grind for 2 hours until the fineness is qualified and the fineness of the paint is below 100 μm, filter, pack, and obtain a vapor phase antirust paint...

Embodiment 2

[0074] One, prepare gas-phase antirust coating according to the following raw material ratio:

[0075] Bisphenol A epoxy resin 30%

[0076] Vapor phase corrosion inhibitor (10% propargyl amine, 12% dimethyl sulfoxide and 78% water) 8%

[0077] Iron Oxide Red 45%

[0078] Auxiliary 3%

[0079] Organic solvent 14%

[0080] Second, the specific preparation method of vapor phase antirust coating:

[0081] (1) Epoxy resin and organic solvent are weighed according to the formula and put into the cylinder;

[0082] (2) Add gas-phase corrosion inhibitors and additives, and stir at low speed for 15 minutes with a high-speed disperser until the dispersion is uniform;

[0083] (3) Add pigments and fillers to the mixture in step (2), stir and disperse at high speed at 1200-1500r / min for 30 minutes, heat up to 55°C, and keep warm for 15 minutes;

[0084] (4) Grind for 2 hours until the fineness is qualified and the fineness of the paint is below 100 μm, filter, pack, and obtain a vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com