A durable superhydrophobic coating and preparation method thereof

A super-hydrophobic coating, durable technology, used in coatings, antifouling/underwater coatings, devices for coating liquids on surfaces, etc. , Improve the degree of adhesion, the effect of good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

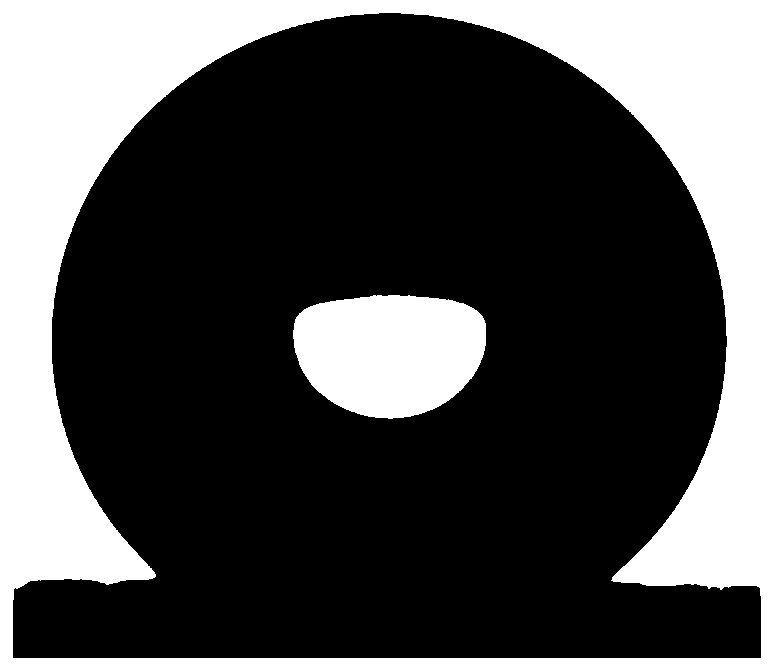

[0022] Under the condition of stirring at a low speed of 400rpm, 0.6 parts of hydrophobic micro-nano titanium dioxide particles, 3 parts of FEVE resin and 0.7 parts of hexamethylene diisocyanate trimer curing agent were successively added to 10 parts of butyl acetate solution, and stirred at a high speed of 1500 rpm for 10 minutes. After ultrasonic dispersion for 5 minutes, the obtained coating was brushed on the surface of the glass sheet and cured at room temperature for 24 hours. The water contact angle was 146.5° and the rolling angle was 23.1°. figure 1 Optical photograph of the water drop contact angle of the obtained coating, figure 2 Scanning electron micrograph of the coating.

Embodiment 2

[0024] Under the condition of 500rpm low-speed stirring, add 1.5 parts of hydrophobic micro-nano fumed silica particles, 6 parts of FEVE resin and 1 part of hexamethylene diisocyanate trimer curing agent to 20 parts of butyl acetate solution, 1500rpm high speed Stir for 15 minutes, then ultrasonically disperse for 10 minutes, brush the obtained paint on the surface of the glass sheet, and obtain several samples. Take out a part of the sample without soaking, and dry it at room temperature for 24 hours to completely cure. Take the remaining sample and dry it at room temperature for 16 hours to reach a semi-cured state. Add 1 part of hexamethylene diisocyanate trimer curing agent to 20 parts of butyl acetate solution, ultrasonically disperse for 10 minutes to mix evenly, and prepare soaking solution. Let the semi-cured coating be immersed in the immersion solution for 30 minutes, take it out and dry it at room temperature for 24 hours to completely cure. The water contact angl...

Embodiment 3

[0026] Under the condition of 500rpm low-speed stirring, 1 part of hydrophobic carbon nanotube particles, 4 parts of FEVE resin and 0.8 part of hexamethylene diisocyanate trimer curing agent were successively added to 15 parts of butyl acetate solution, and 1800 rpm was stirred at high speed for 10 minutes. Then ultrasonically disperse for 10 minutes, brush the resulting paint on the surface of the glass sheet, and dry it at room temperature for 20 hours to make it semi-cured. Add 0.5 parts of hexamethylene diisocyanate trimer curing agent to 20 parts of butyl acetate solution, ultrasonically disperse for 15 minutes to mix evenly, and prepare soaking solution. Let the semi-cured coating be immersed in the soaking solution for 60 minutes, take it out and dry it at room temperature for 24 hours to completely cure. The water contact angle of the obtained coating is 159.4°, and the rolling angle is 1.0°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com