PVC furniture film water-based foaming ink and preparation method thereof

A technology of foaming ink and furniture film, applied in ink, household utensils, applications, etc., can solve problems such as printing workers and environmental damage, consumers' home health damage, flammability and explosion, etc., to solve high foaming, foaming High height and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] (1) Preparation of monomer dropping phase: 23.012 parts of methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), 20.548 parts of methyl acrylate monomer (Shanghai Mairuier Chemical Technology Co., Ltd.) ), 0.44 parts of glycidyl methacrylate monomer (Jiangxi Ruixiang Chemical Co., Ltd.), 0.00368 parts of isooctyl 3-mercaptopropionate (Sinopharm Chemical Reagent Co., Ltd.) chain transfer reagent and 2 parts of ER-40 (ADEKA company) non-ionic emulsifier is stirred and dissolved 40min with the speed of 500rpm, obtains the monomer dropwise addition phase;

[0041] (2) Preparation of the primer phase: 1.3 parts of DowFax TM 8390 (DOW company) anionic emulsifier, 0.7 part of ER-40 (ADEKA company) nonionic emulsifier, 0.11 part of AMP-95 (Dow company) pH buffering agent, 0.08 part of potassium persulfate (Wujiang Sanyuan fine Chemical Co., Ltd.) initiator joins 39 parts of deionized water, stirs and dissolves with the speed of 400rpm, obtains the base phase;

...

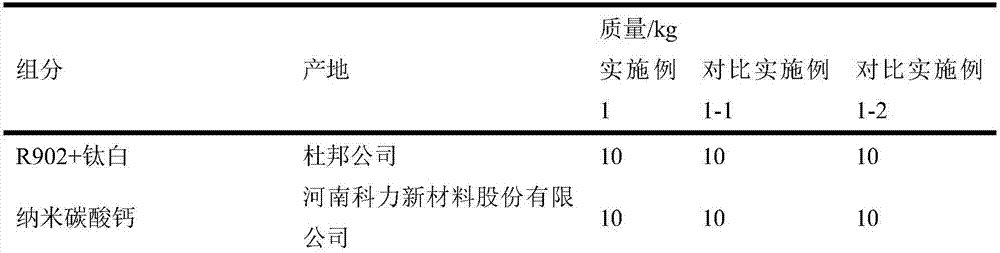

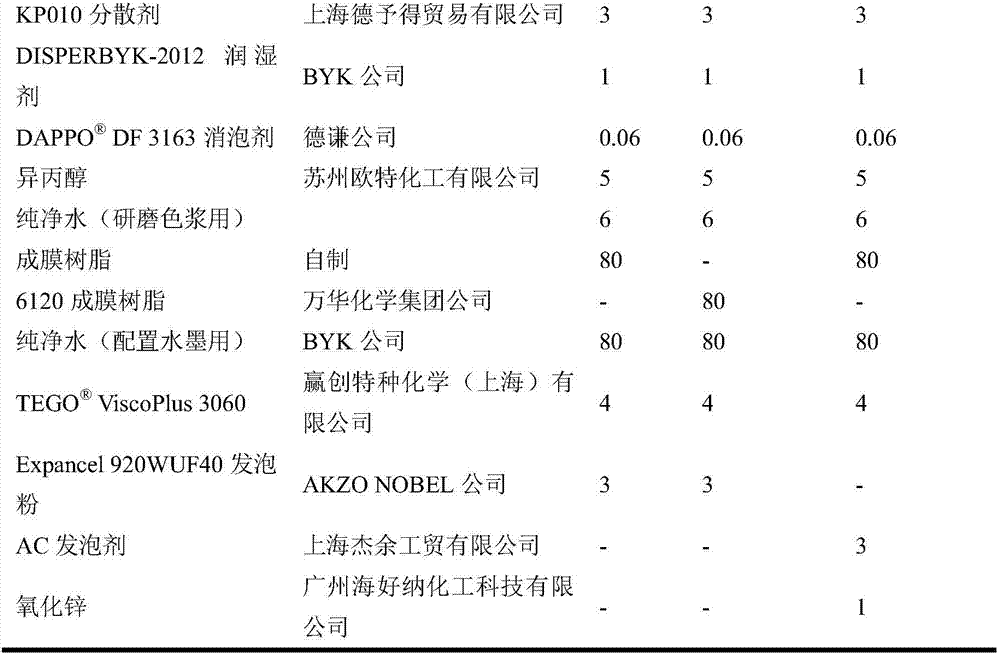

Embodiment 1

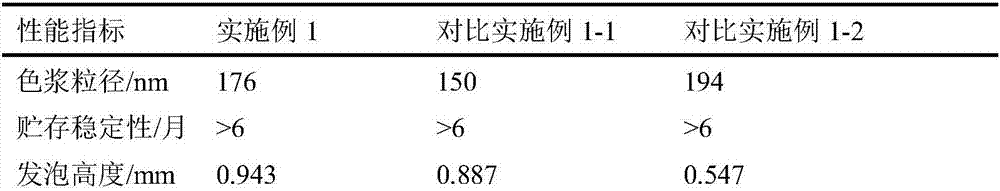

[0048] According to the formula amount of Example 1 in Table 1, pure water, isopropanol, dispersant, wetting agent and defoamer were added to the dispersing kettle in turn at room temperature, and the pigment, The filler was stirred and mixed evenly at a speed of 150rpm, and then transferred to a horizontal sand mill (TBM-50, Taiyi (Shanghai) Industrial Co., Ltd.) for two passes of grinding, and the material was filtered to obtain a water-based color paste. Then add pure water, the above-mentioned water-based color paste, film-forming resin, thickener and foaming powder into the dispersion tank in turn, and then filter and discharge the material after stirring at a speed of 1200rpm for 1h to obtain the PVC furniture film water-based foaming ink .

Embodiment 2

[0060] According to the formula amount of Example 2 in Table 3, pure water, alcohol, dispersant, wetting agent and defoamer are added to the dispersing kettle successively at room temperature, and after stirring and mixing at a speed of 150rpm, pigments and fillers are added to Stir at a speed of 300rpm and mix evenly, then transfer to a horizontal sand mill (TBM-50, Taiyi (Shanghai) Industrial Co., Ltd.) to grind for 2 passes, filter and discharge to obtain a water-based color paste. Then add pure water, the above-mentioned water-based color paste, film-forming resin, thickener and foaming powder into the dispersion tank in sequence, stir at a speed of 1000rpm for 1.5h, and then filter the material to obtain the PVC furniture film water-based foam ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com