Concrete water reducer and preparation method thereof

A technology of concrete water reducing agent and mixed solution, applied in the field of water reducing agent, can solve the problems of poor water retention of concrete, restrictions on the application of sulfamate high-efficiency water reducing agent, bleeding and segregation, etc., and achieve high water reducing rate, Effect of improving fluidity and improving bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

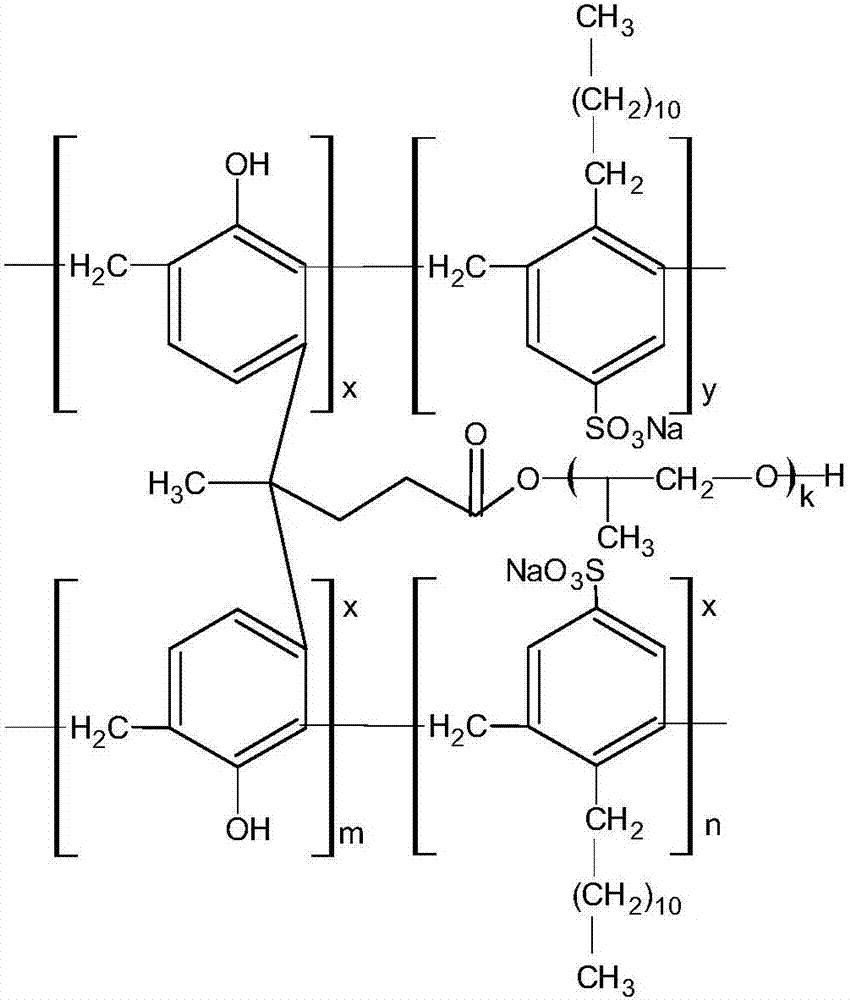

Image

Examples

Embodiment 1

[0024] A preparation method of concrete water reducer, comprising the steps of:

[0025] a) Add 100 parts by weight of 4,4-bis(4-hydroxyphenyl)valeric acid, 355 parts by weight of polypropylene glycol and 8.6 parts by weight of p-toluenesulfonic acid into the reaction vessel, mix well and carry out esterification at 151°C Reaction, obtains modified bisphenolic acid;

[0026] b) Mixing modified bisphenolic acid, 18 parts by weight of sodium citrate, and 38 parts by weight of anhydrous dodecylbenzenesulfonic acid in 2300 parts by weight of water to obtain a mixed solution with a pH value of 7.2;

[0027] c) Add 98 parts by weight of 37wt% industrial formaldehyde to the mixed solution, control the rate of addition to complete the dropwise addition within 1.5 hours, and heat the mixed solution to 46°C, react for 0.7h, continue to heat the mixed solution to 77°C, and react After 7.5 hours, an aqueous solution containing a water reducing agent was obtained.

Embodiment 2

[0029] A preparation method of concrete water reducer, comprising the steps of:

[0030] a) Add 100 parts by weight of 4,4-bis(4-hydroxyphenyl)valeric acid, 360 parts by weight of polypropylene glycol and 9 parts by weight of p-toluenesulfonic acid into the reaction vessel, mix them uniformly and carry out esterification at 155°C Reaction, obtains modified bisphenolic acid;

[0031] b) Mixing modified bisphenolic acid, 18 parts by weight of sodium citrate, and 40 parts by weight of anhydrous dodecylbenzenesulfonic acid in 3000 parts by weight of water to obtain a mixed solution with a pH value of 7.3;

[0032] c) Add 110 parts by weight of 37wt% industrial formaldehyde dropwise to the mixed solution, control the rate of addition to complete the dropwise addition within 1.3 hours, and heat the mixed solution to 47°C, react for 0.8h, and continue heating the mixed solution to 80°C, After 8 hours of reaction, an aqueous solution containing a water reducing agent was obtained.

Embodiment 3

[0034] A preparation method of concrete water reducer, comprising the steps of:

[0035] a) Add 100 parts by weight of 4,4-bis(4-hydroxyphenyl)valeric acid, 365 parts by weight of polypropylene glycol and 9.5 parts by weight of p-toluenesulfonic acid into the reaction vessel, mix well and carry out esterification at 155°C Reaction, obtains modified bisphenolic acid;

[0036] b) Mix modified bisphenolic acid, 18.3 parts by weight of sodium citrate, and 45 parts by weight of anhydrous dodecylbenzenesulfonic acid in 3300 parts by weight of water to obtain a mixed solution with a pH value of 7.4;

[0037] c) Add 120 parts by weight of 37wt% industrial formaldehyde dropwise to the mixed solution, control the rate of addition to complete the dropwise addition within 1.8 hours, and heat the mixed solution to 47.5°C, react for 1.2h, and continue heating the mixed solution to 90°C, After 8 hours of reaction, an aqueous solution containing a water reducing agent was obtained.

[0038]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com