Method for treating biomass gasified gas washing wastewater and for resource utilization of wastewater treatment product

A wastewater treatment and biomass technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution, inconvenient transportation, difficult to dissolve, etc., and achieve strong Adsorption capacity, good adsorption effect, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The amount of waste water produced is 5m 3 / h, the biomass gasifier works continuously for 24 hours a day, and the daily waste water production is 120m 3 / d.

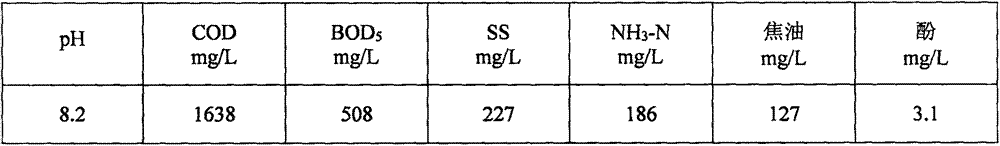

[0030] The wastewater quality indicators are as follows:

[0031]

[0032] Pass the waste water from biomass gasification and scrubbing into the cyclone separator to remove substances with a density greater than water;

[0033] After that, the waste water is passed into the middle pool to buffer the water quality, reduce the water temperature, remove large particles, and adjust the pH value of the waste water to 5.0;

[0034] Afterwards, the waste water flows into the coagulation sedimentation tank, and the addition of 0.07% polyaluminum chloride (made into a 5% solution before use) by mass percentage is added, and after rapid stirring for 30 seconds, slow stirring for 20 minutes, and then adding 0.003% polyaluminum chloride Acrylamide (prepared as a 0.2% solution before use), stirred at a slow speed for 10...

Embodiment 2

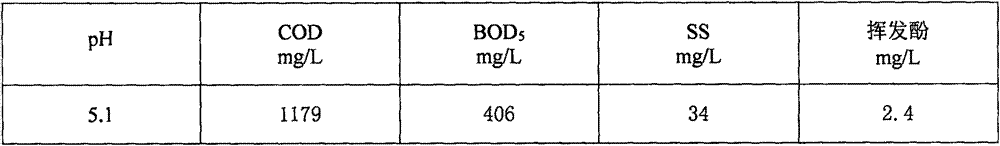

[0042] Take the wastewater treated in the coagulation section of the biomass gasification wastewater of the factory, and the water quality indicators are as follows:

[0043]

[0044] Pass the wastewater or adjust the pH value into the adsorption tower filled with walnut shell activated carbon and coconut shell activated carbon respectively. The filling amount of activated carbon is 4kg / t wastewater, and the residence time of the wastewater in the adsorption tower is controlled by the circulation pump to 120 minutes.

[0045] Afterwards, the waste water flows into two clear water tanks respectively.

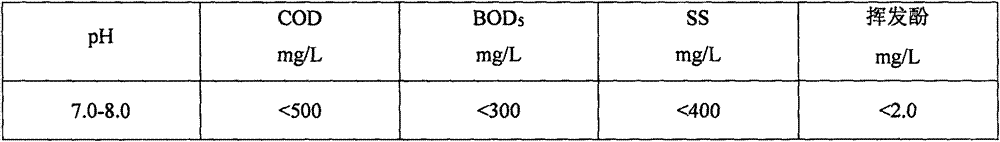

[0046] After the wastewater is treated by the above process, the pollutants in the wastewater are removed to varying degrees. The measured water quality indicators after the two kinds of activated carbon adsorption treatment are as follows:

[0047]

[0048] Walnut shell activated carbon has a better adsorption effect on organic matter in wastewater than coconut shell activat...

Embodiment 3

[0050] Collect waste walnut shell activated carbon and anthracite after many times of adsorption, and the analysis results are as follows:

[0051]

[0052] Grind waste walnut shell activated carbon and anthracite into powder below 180 mesh.

[0053] After that, 66 g of anthracite powder, 0.24 g of sodium methylene naphthalenesulfonate-styrenesulfonate-sodium maleate and 40 ml of deionized water were weighed.

[0054] Then mix sodium methylene naphthalene sulfonate-sodium styrene sulfonate-sodium maleate with deionized water and stir well until completely dissolved.

[0055] Then add anthracite powder, mix and stir evenly, and make coal water slurry 1.

[0056] Afterwards, the deionized water of spent walnut shell activated carbon and 33g of anthracite powder, 0.24g of sodium methylenenaphthalenesulfonate-styrenesulfonate-sodium maleate and 40ml of deionized water were weighed respectively.

[0057] Then mix sodium methylene naphthalene sulfonate-sodium styrene sulfonate-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com