Preparation process of mineral composite material capable of adjusting moisture

A composite material and preparation technology, applied in the direction of alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of long humidity balance time, small amount of moisture absorption and desorption, and uneven moisture absorption and desorption process, etc. problem, to achieve the effect of increasing adsorption capacity and exchange capacity, and increasing pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

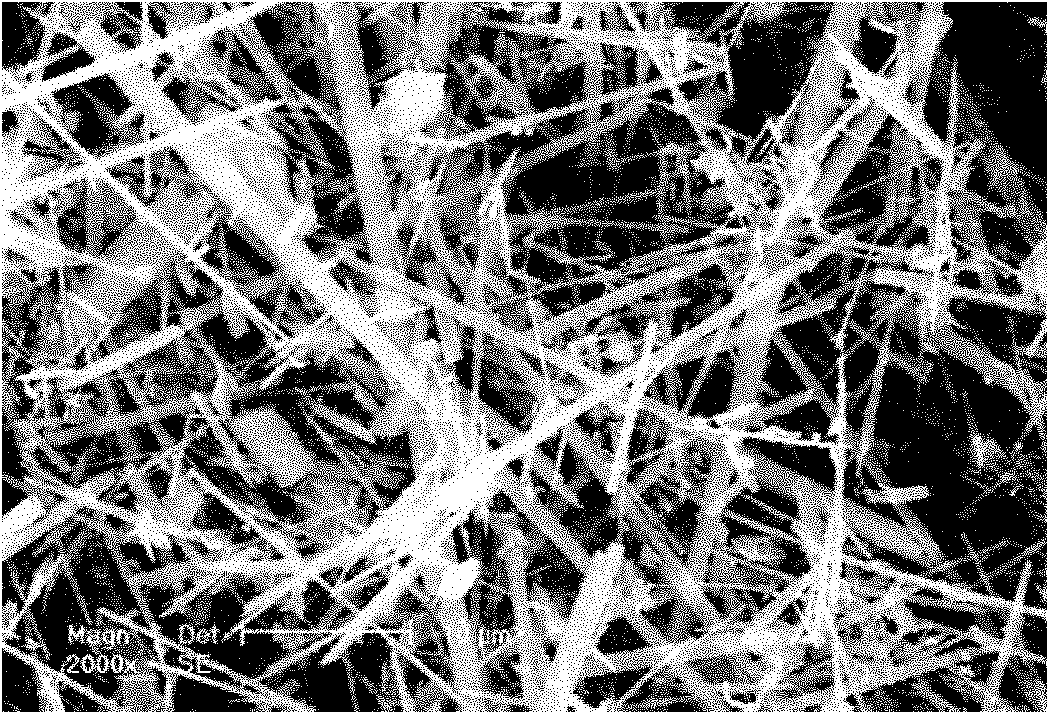

Image

Examples

Embodiment 1~3

[0034] The process optimization procedure for preparing self-humidity functional materials is as follows:

[0035] 1. Mix sepiolite with sulfuric acid with a concentration of 15%, stir with a magnetic stirrer at room temperature for 6 to 14 hours, and then filter with a circulating water-type multi-purpose vacuum pump and a Buchner funnel to obtain a filter cake;

[0036] 2. Crush the filter cake, mix it with deionized water, then stir, wash, and filter again, and test the SO in the filtrate with barium nitrate solution 4 2- ion;

[0037] 3. Repeat step 2 repeatedly until no SO is detected in the filtrate 4 2- ion, stop cleaning;

[0038] 4. Put the filter cake into an electric vacuum drying oven, and dry it at 105°C to constant weight;

[0039] 5. Put the dried filter cake into a constant temperature drying oven or a box-type resistance furnace, heat and roast for heat activation, and the treatment time is 8 hours. Then take it out and crush it to get the humidity contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com