Reaction cavity and semiconductor processing device

A reaction chamber and reaction gas technology, which is applied in the manufacture of semiconductor/solid-state devices, discharge tubes, electrical components, etc., can solve the problems of uneven distribution of electromagnetic field, uneven voltage distribution, and large voltage difference, so as to achieve the goal of weakening the electric field. The effect of uniformity, the effect of improving the uniformity of density distribution, and the effect of improving the uniformity of electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order for those skilled in the art to better understand the technical solution of the present invention, the reaction chamber and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

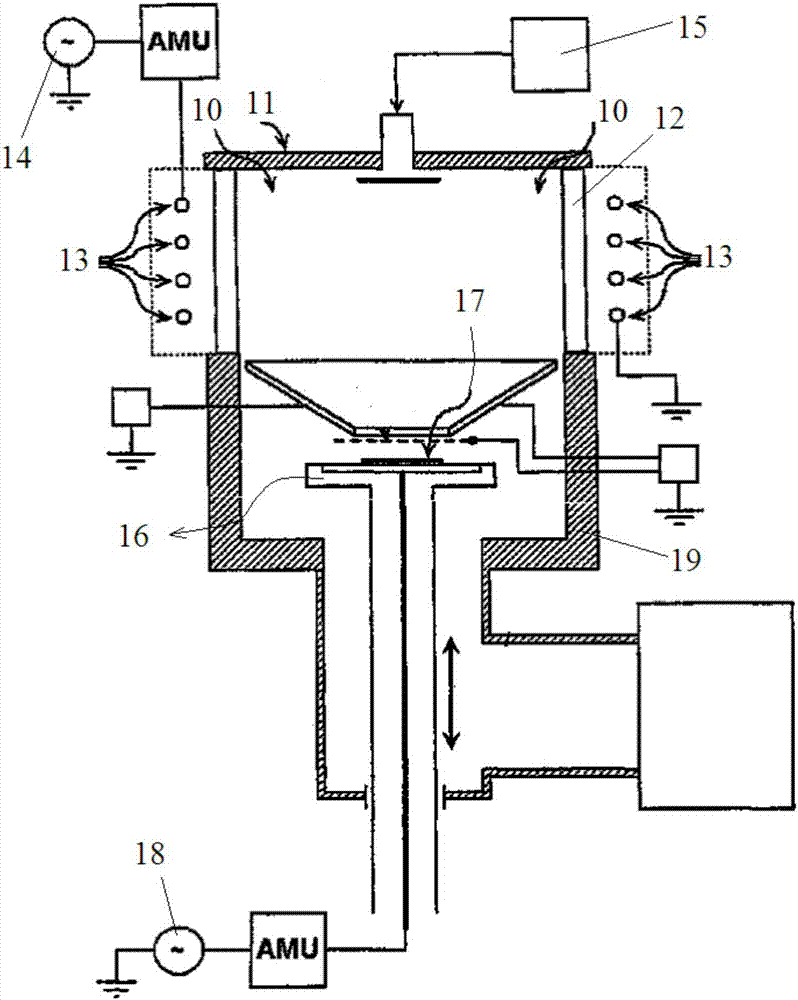

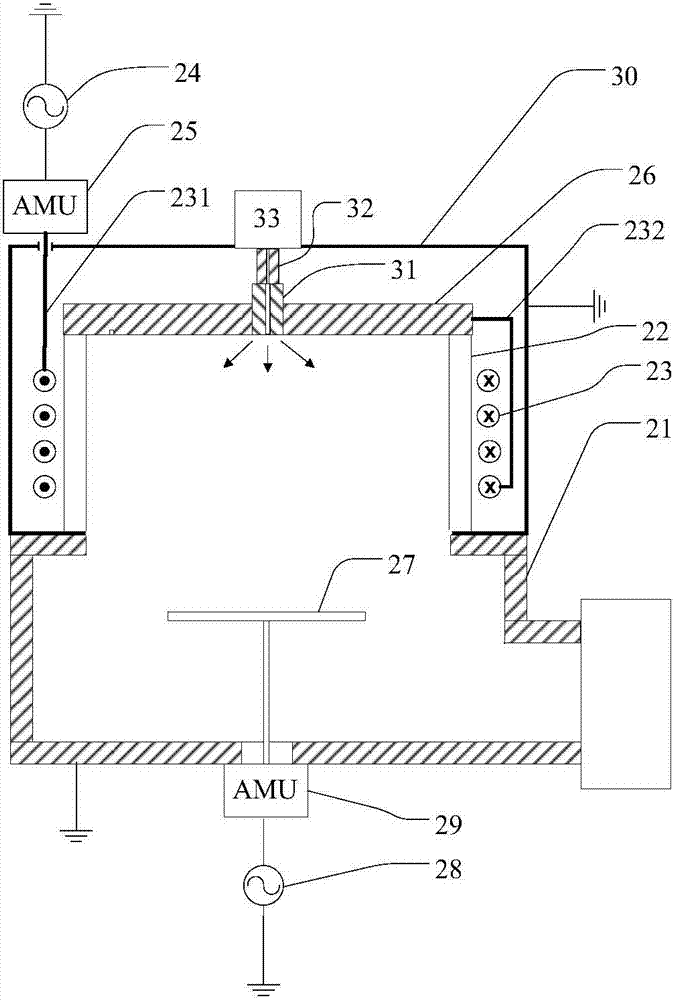

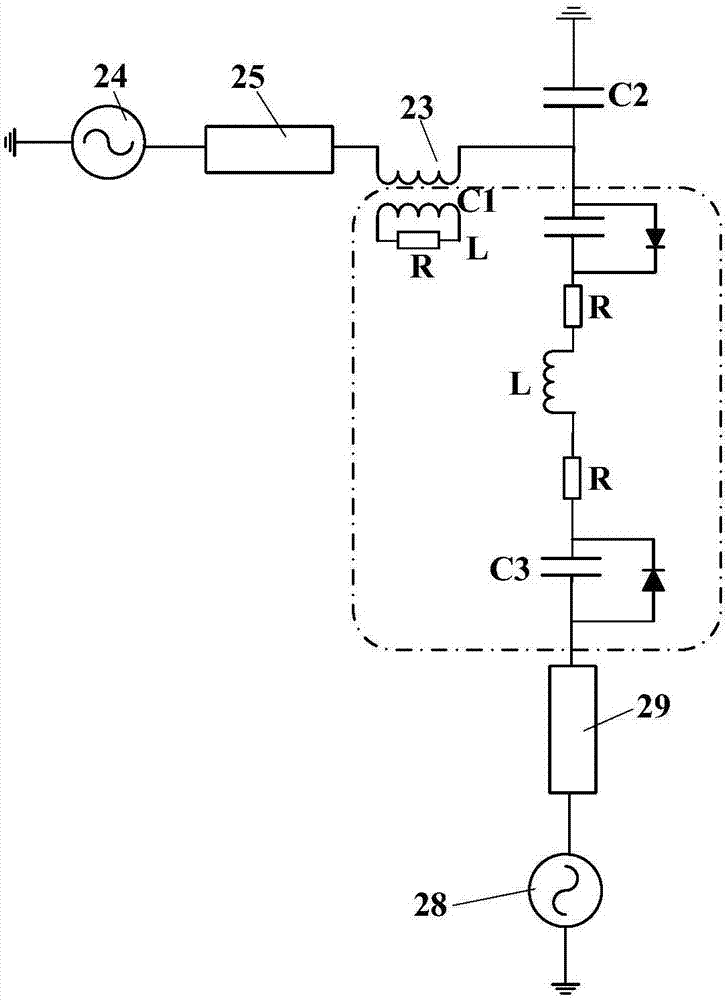

[0033] Figure 2A A cross-sectional view of the reaction chamber provided by the first embodiment of the present invention. see Figure 2A , the reaction chamber includes an upper electrode device and a lower electrode device. Wherein, the upper electrode device includes a dielectric cylinder 22, a coil 23, an upper power supply 24, a first matching device 25, and an upper electrode assembly. The lower electrode device includes a base 27 , a lower power supply 28 , and a second matcher 29 .

[0034] Wherein, the chamber wall 21 of the reaction chamber is grounded, and the chamber wall 21 surrounds and forms a cavity structure with an opening at the top; the medium cylinder 22 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com