Construction method for novel drilling structure for in-situ leaching of uranium

A construction method and in-situ leaching uranium mining technology are applied in drilling equipment and methods, mining fluids, earth-moving drilling, etc., and can solve the problems of long construction period, high labor intensity for well cleaning, poor sediment resistance, etc. The effect of long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

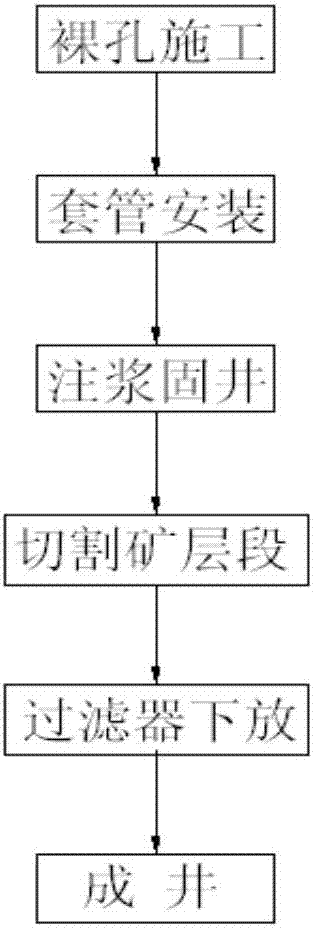

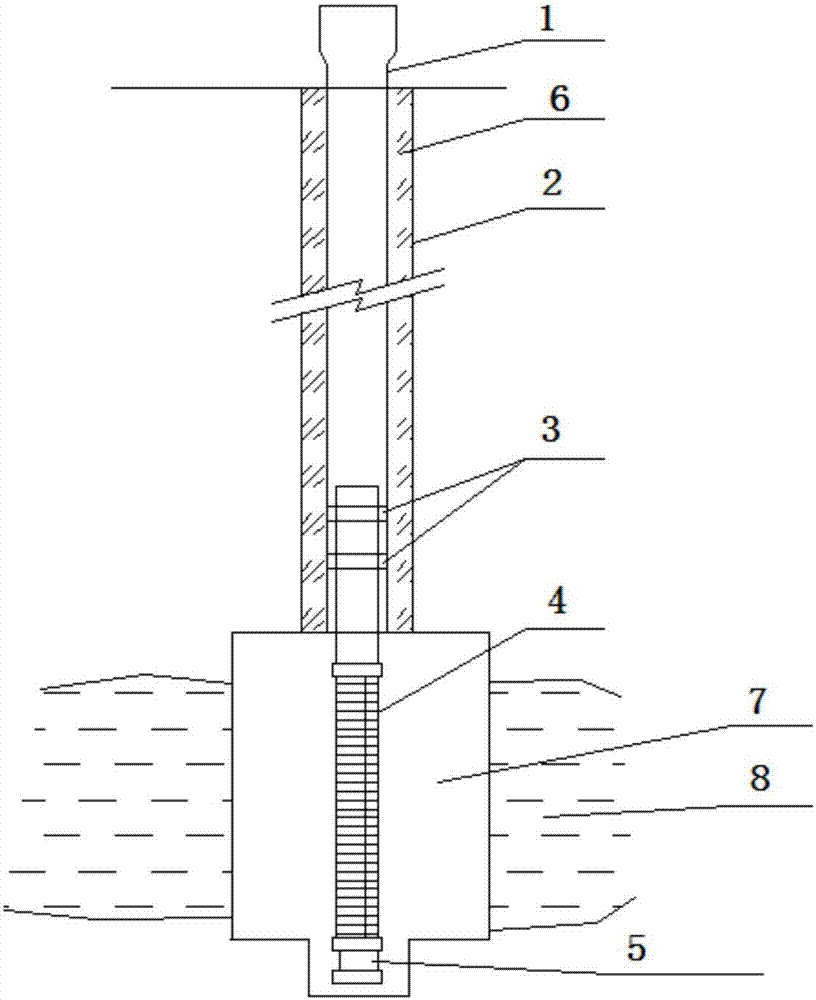

[0025] Such as Figure 1 to Figure 2 Shown, a kind of in-situ leaching mining uranium novel drilling structure construction method of the present invention, it comprises the following steps:

[0026] (a) Open hole drilling uses a Φ215mm drill bit to open the hole, drills to the upper 8m of the ore seam, replaces the Φ151mm drill bit, and drills to the design depth;

[0027] (b) After replacing the thick mud in the hole with thin mud, conduct a comprehensive exploration well, determine the position of the ore layer, determine the length of the well pipe, the position and length of the filter, and use a Φ215mm roller cone bit to ream the hole to the required depth to obtain the bare 2; The sand content of the thin mud mentioned above is 3 .

[0028] (c) After reaming, the bare hole 2 is flushed with thin mud circulation, and then the configured casings 1 are sequentially lowered into the bare hole 2; the length of the first casing at the top of the well pipe is fixed at 1 meter...

Embodiment 2

[0034] Such as Figure 1 to Figure 2 Shown, a kind of in-situ leaching mining uranium novel drilling structure construction method of the present invention, it comprises the following steps:

[0035] (a) Open hole drilling uses a Φ180mm drill bit to open the hole, drills to the upper 5m of the ore seam, replaces the Φ130mm drill bit, and drills to the design depth;

[0036] (b) After replacing the thick mud in the hole with fresh thin mud, conduct a comprehensive exploration well, determine the position of the ore layer, determine the length of the well pipe, the position and length of the filter, and use a Φ180mm roller cone bit to ream the hole to the required depth to obtain an open hole 2 ; The sand content of the fresh thin mud is less than 5%, the viscosity is less than 30s, and the density is 1.0g / cm 3 .

[0037] (c) After reaming, the bare hole 2 is flushed with thin mud circulation, and then the configured casing 1 is sequentially lowered into the bare hole 2; the l...

Embodiment 3

[0043] Such as Figure 1 to Figure 2 Shown, a kind of in-situ leaching mining uranium novel drilling structure construction method of the present invention, it comprises the following steps:

[0044] (a) Open hole drilling uses a Φ230mm drill bit to open the hole, drills to the upper 10m of the ore seam, replaces the Φ170mm drill bit, and drills to the design depth;

[0045] (b) After replacing the thick mud in the hole with fresh thin mud, carry out a comprehensive exploration well, determine the position of the ore layer, determine the length of the well pipe, the position and length of the filter, and use a Φ230mm roller cone bit to ream the hole to the required depth to obtain the open hole 2; The sand content of the fresh thin mud is 3 .

[0046] (c) After reaming, the bare hole 2 is flushed with thin mud circulation, and then the configured casing 1 is sequentially lowered into the bare hole 2; the length of the first casing at the top of the well pipe is fixed at 1.2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com