Preparation method and use of tungsten oxide/bismuth oxybromide composite material

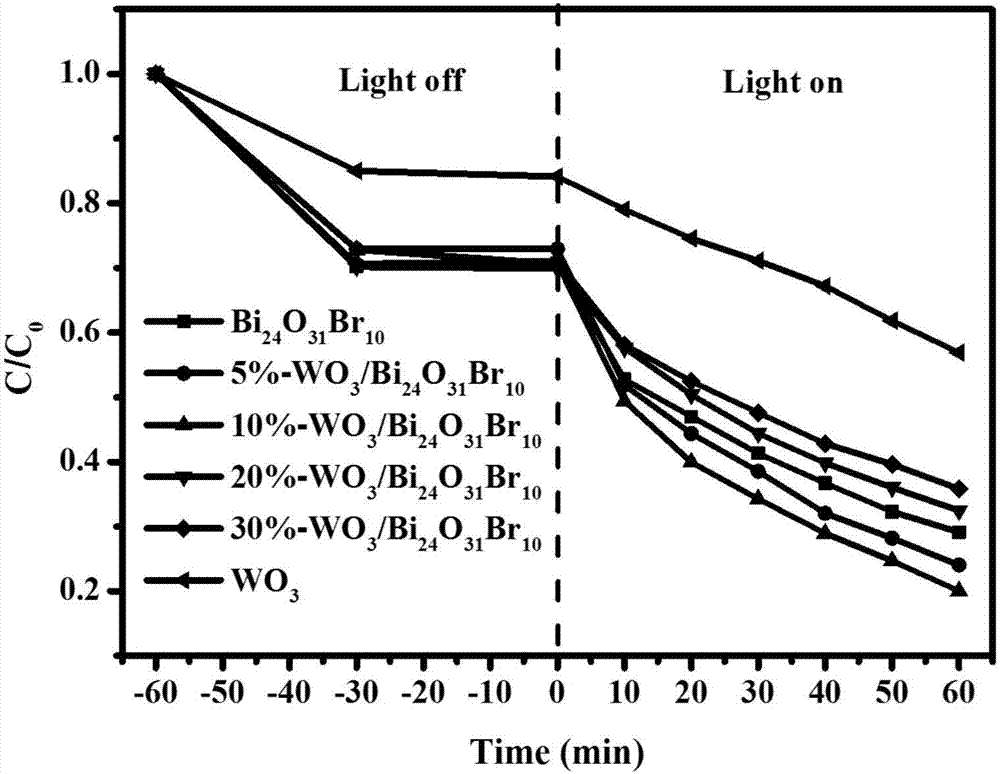

A technology of bismuth oxybromide and a composite material, applied in the field of nanomaterials, can solve the problems of low utilization rate of visible light, easy recombination of holes and electrons, etc., and achieves the effects of good cyclic stability, simple process, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

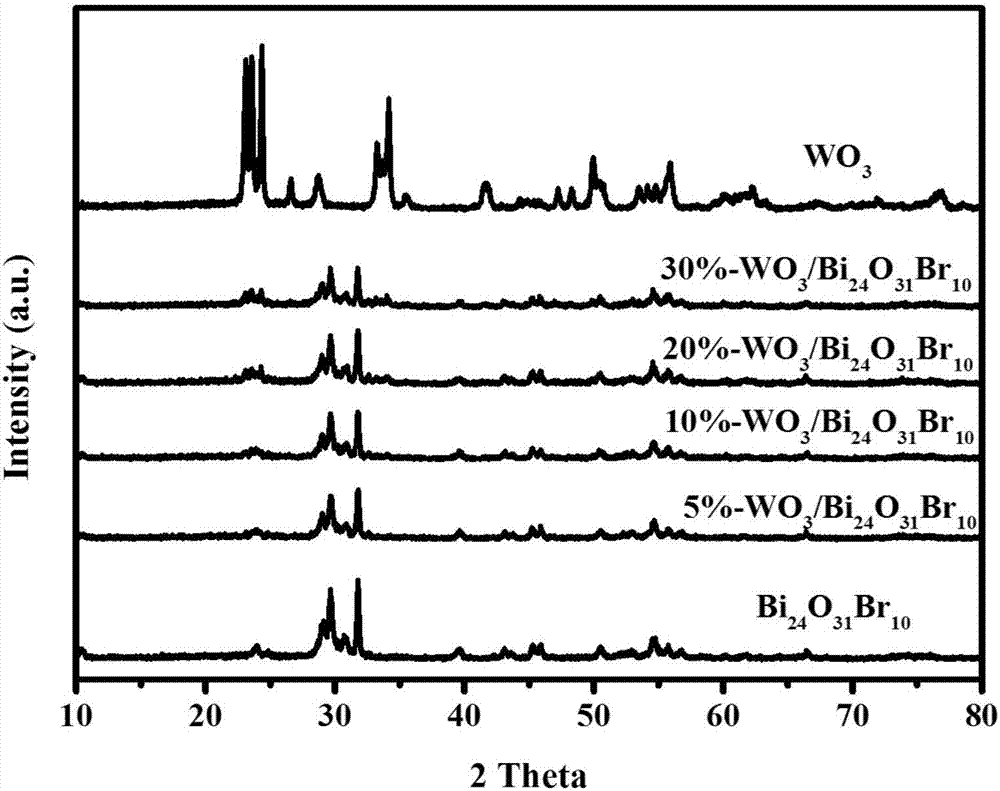

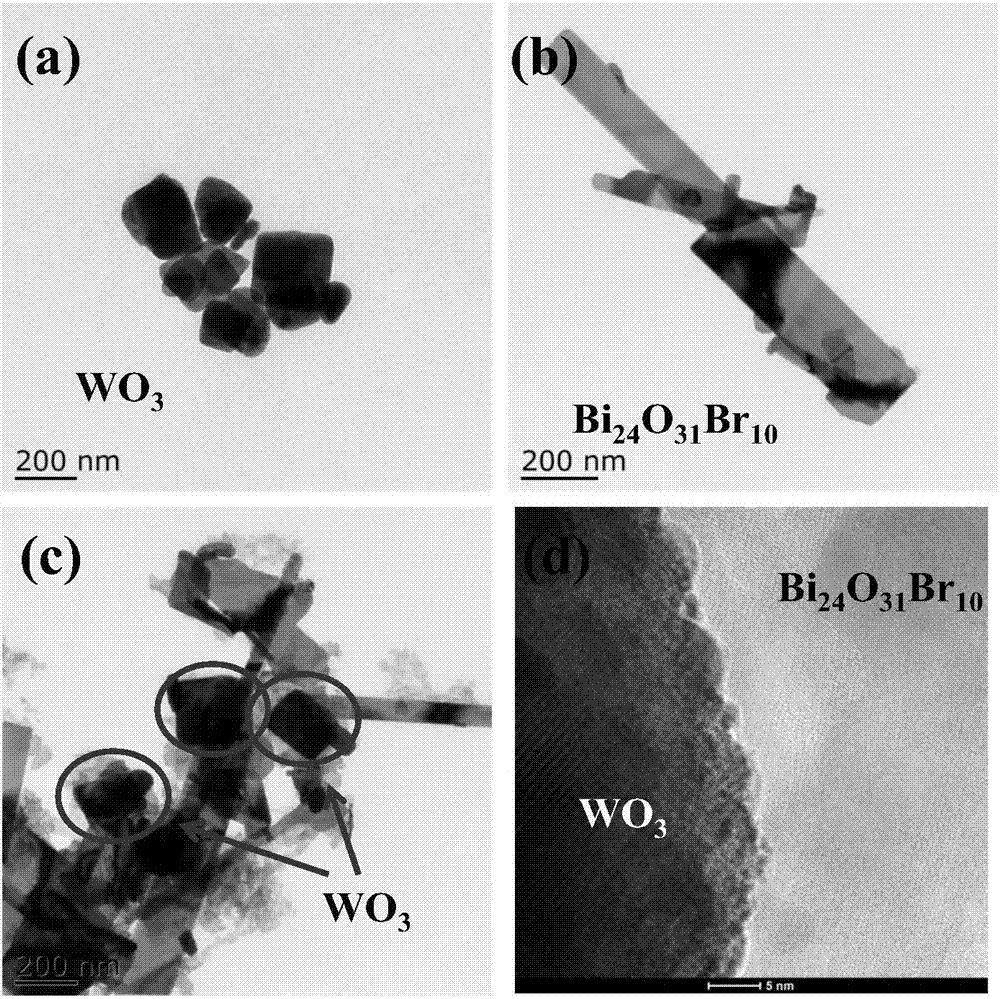

[0026] Example 1 Bi 24 O 31 Br 10 Preparation

[0027] Weigh 0.97g of bismuth nitrate pentahydrate in a beaker, add 10mL of ethylene glycol, ultrasonic and stir for 30min to fully dissolve; weigh 0.196g of ammonium bromide in another beaker, add 25mL of deionized water to it, Stir for 20 minutes to dissolve; mix the two solutions and stir for 20 minutes to obtain a white suspension; then add 1.2 mL ethanolamine and continue stirring for 20 minutes; then transfer the resulting suspension to a 50 mL reactor lined with polytetrafluoroethylene , Put it in an oven at 160℃ to react for 12h; after it is naturally cooled to room temperature, the solid is centrifuged out, washed with deionized water and absolute ethanol 3 times, centrifuged and dried at 60℃. Take it out and grind it to powder with a mortar for use.

Embodiment 2

[0028] Example 2 WO 3 Preparation

[0029] Weigh 0.5g sodium tungstate dihydrate and 0.3g citric acid monohydrate in a beaker, add 30mL deionized water and stir for 20min until completely dissolved, add 6mol L dropwise -1 Adjust the pH of the solution to 1 with the hydrochloric acid solution, continue to stir for 1 hour until a yellow suspension is obtained, and then transfer the resulting suspension to a 50 mL reactor, and place it in an oven for hydrothermal reaction at 120°C for 12 hours; after it is naturally cooled to room temperature , Wash with deionized water and absolute ethanol 3 times, centrifuge and dry at 60℃. Take it out, grind it to powder with a mortar, transfer it to a semi-closed crucible, and then transfer it to a temperature-programmed tube furnace for calcination at 500°C for 2h.

Embodiment 3

[0030] Example 3 5%-WO 3 / Bi 24 O 31 Br 10 Preparation of composite materials

[0031] Weigh 0.0053g WO 3 And 0.1g Bi 24 O 31 Br 10 The powder was dissolved in 20mL and 60mL of deionized water respectively, and then sonicated and stirred in an ultrasonic cleaning machine for 30 minutes to make them uniformly dispersed; then WO 3 Suspension 2 and Bi 24 O 31 Br 10 The suspension 1 was mixed and stirred for 12h. Finally, the suspension 3 was transferred to a 100mL reactor and placed in an oven for hydrothermal reaction at 160℃ for 12h; after it was naturally cooled to room temperature, deionized water and absolute ethanol were used Washed 3 times, centrifuged and dried at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com