VOC adsorption equipment for on-line measurement of VOC concentration and method thereof

A technology of adsorption equipment and adsorbent, applied in the field of gas cleaning equipment, can solve the problems of large power consumption, large energy consumption, and increased factory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The device and method of the present invention will be described below in conjunction with specific embodiments and accompanying drawings. It should be emphasized that the illustration here is only an example, and other implementations utilizing the present invention are not excluded.

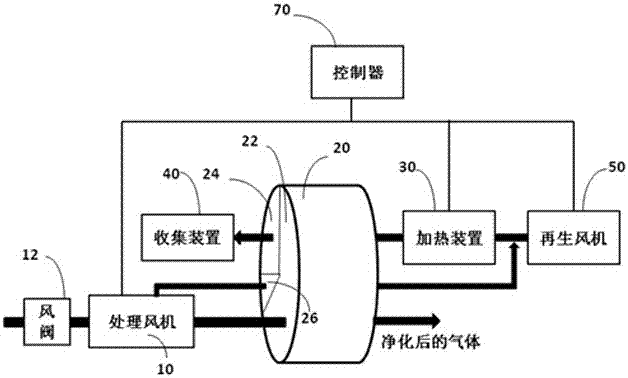

[0054] figure 1 It is a structural schematic diagram of an embodiment of the VOC adsorption equipment of the present invention. The adsorption equipment can be applied in many fields, for example, it can be used to remove VOC gas generated in the production of photoresist coating equipment (equipment to be purified). When in use, the exhaust gas outlet of the equipment to be purified or the area can be connected to the adsorption equipment, and the gas to be purified generated during the operation of the equipment to be purified is continuously introduced into the adsorption equipment. The adsorption equipment can separate the VOC components in it, so that the purified gas can be recycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com