Preparation method for anti-corrosion zirconia/poly(lactic-co-glycolic acid) (PLGA) hybrid coating based on atomic layer deposition

An atomic layer deposition and glycolic acid technology, applied in coating, medical science, tissue regeneration, etc., can solve the problems of magnesium metal losing mechanical properties, failing to achieve clinical effects, unable to play a role in fixation and protection, etc. Controllable, simple method and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

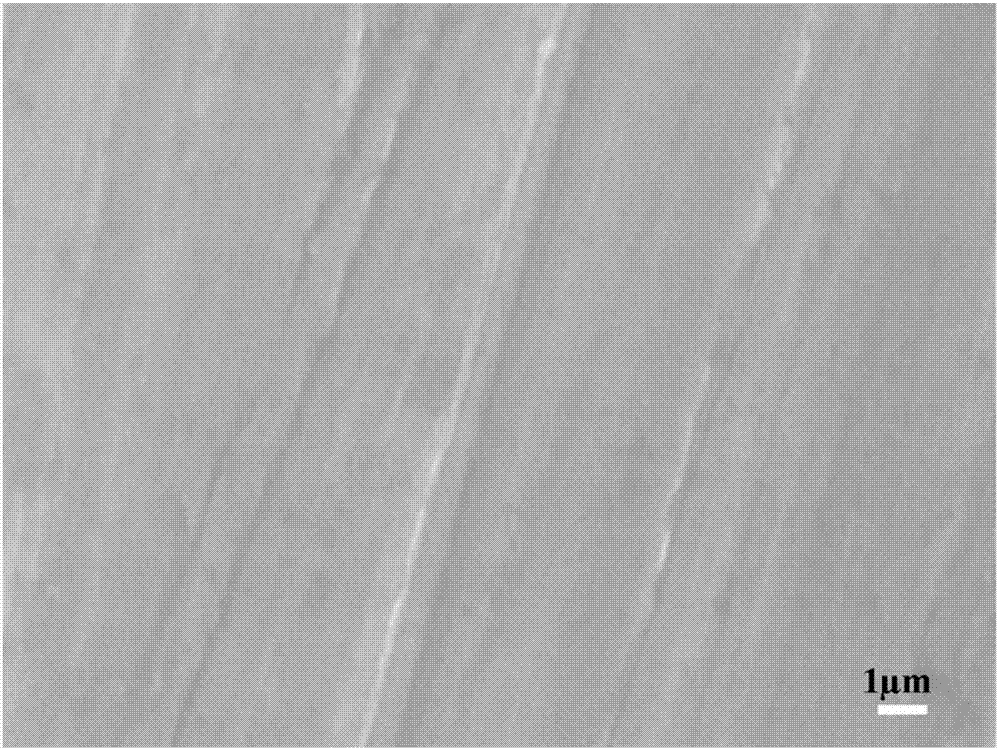

[0025] S1. The magnesium metal disc (16mm*16mm*5mm) is polished step by step with sandpaper as a substrate (the surface structure and topography is shown in figure 1 shown), then the substrate was ultrasonicated in ethanol and acetone for 30 min, and then dried naturally for later use;

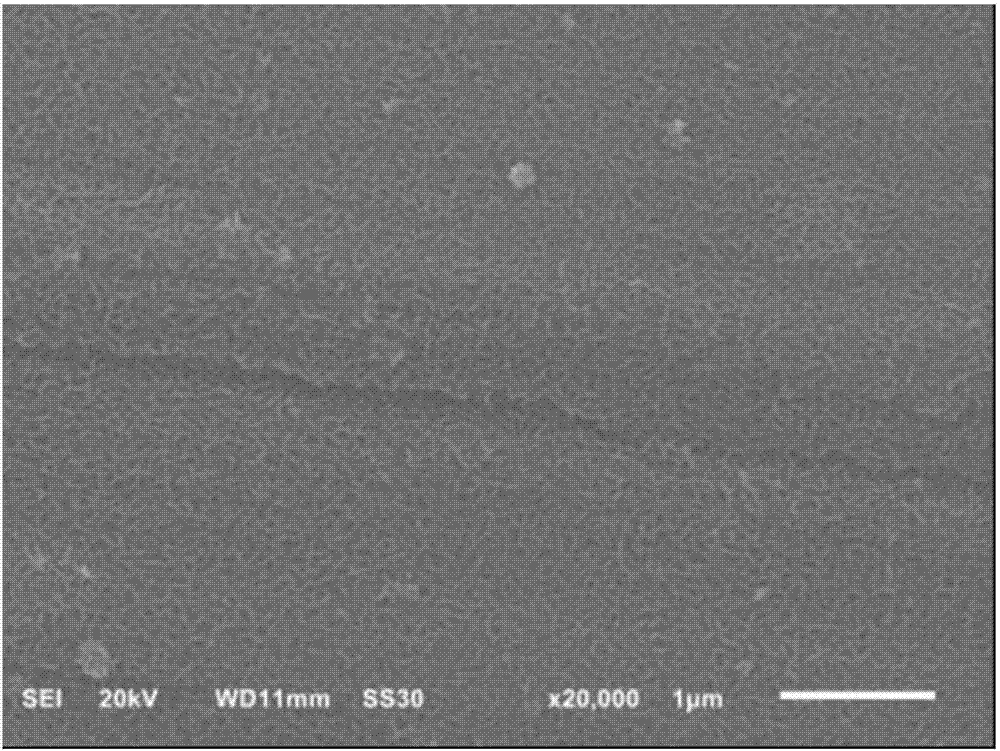

[0026] S2. Perform atomic layer deposition on the dried substrate in step S1: specifically, heat the zirconium source to 150°C, then use 35°C deionized water as the O source, the deposition temperature is 250°C, and perform 100 cycles, and once The cycle consists of four (dimethylamino) zirconium pulses for 30ms, high-purity nitrogen cleaning for 20s, deionized water pulses for 150ms, and high-purity nitrogen cleaning for 20s; the substrate with zirconia coating on the surface can be obtained (the surface structure topography map like figure 2 shown);

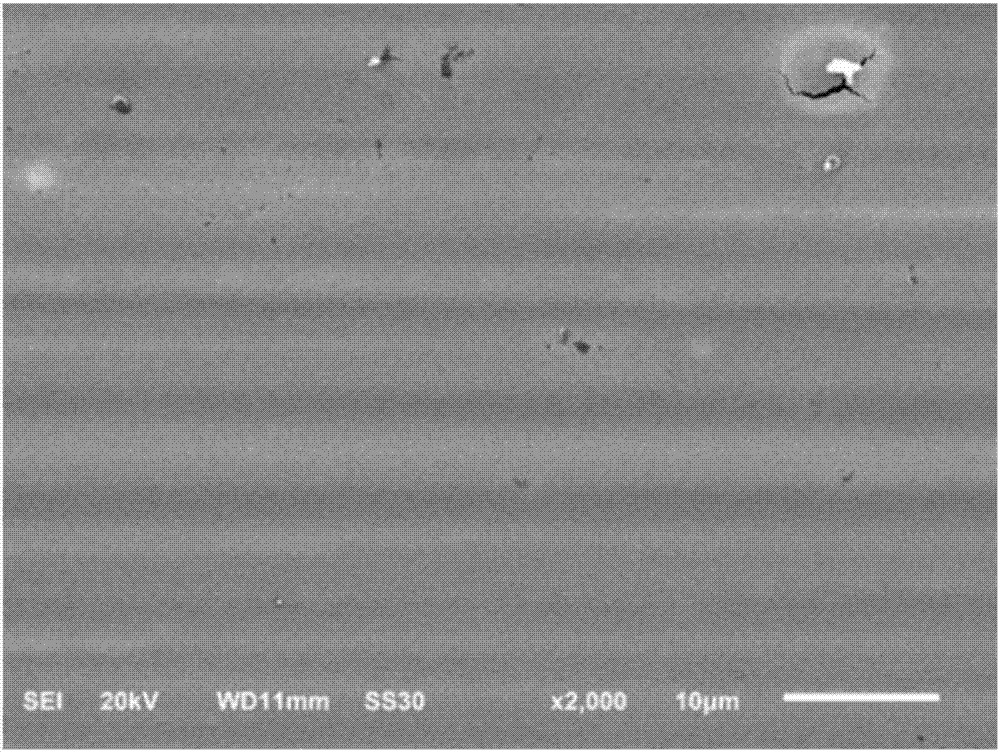

[0027] S3, configure the PLGA (polylactic acid-glycolic acid copolymer) solution of 4% (w / v), and get 0.4ml dropwise on the material that s...

Embodiment 2

[0030] The difference from Example 1 is:

[0031] In step S2: the atomic layer deposition parameters are: the zirconium source is heated to 150°C, then 35°C deionized water is used as the O source, the deposition temperature is 250°C, 25 cycles are performed, and one cycle consists of tetrakis(dimethylamino)zirconium Pulse 30ms, high-purity nitrogen cleaning 20s, deionized water pulse 150ms, high-purity nitrogen cleaning 20s.

Embodiment 3

[0033] The difference from Example 1 is:

[0034] In step S2: the atomic layer deposition parameters are: the zirconium source is heated to 150°C, then 35°C deionized water is used as the O source, the deposition temperature is 200°C, 100 cycles are performed, and one cycle consists of tetrakis (dimethylamino) zirconium Pulse 30ms, high-purity nitrogen cleaning 20s, deionized water pulse 150ms, high-purity nitrogen cleaning 20s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com