Manufacturing method of micro lens array

A technology of microlens arrays and microlenses, which is applied in the fields of lenses, optics, instruments, etc., can solve the problems of low processing precision and long processing cycle of microlens arrays, and achieve the effects of reducing production costs, improving production efficiency, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

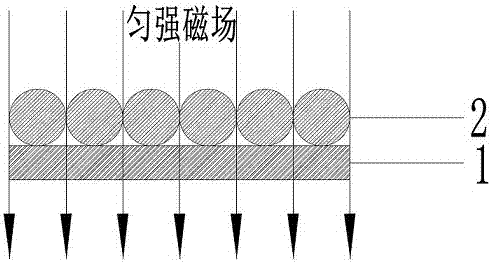

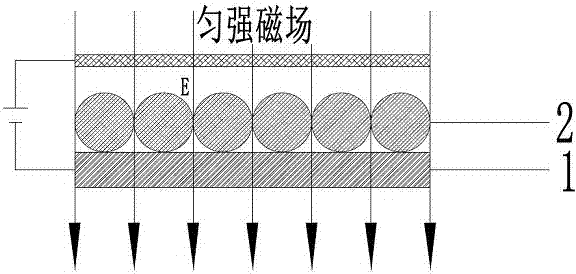

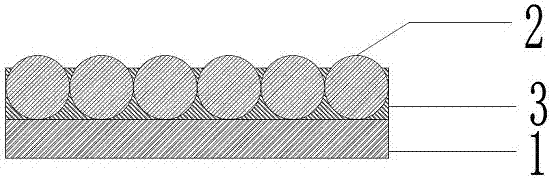

[0018] In this embodiment, a single layer of magnetic colloid particles is used as a mask, and an electrodeposition process is used to manufacture a microlens master mold. The embodiment will be described below with reference to the accompanying drawings.

[0019] (1) A magnetic field is used to induce self-assembled magnetic colloidal particle 2 monolayer film on the substrate 1 . A material with a smooth surface is selected as the substrate 1, and the substrate 1 is cleaned and dried alternately with organic solvents (such as acetone, ethanol) and distilled water. A certain amount of suspension of magnetic colloidal particles 2 is drop-coated on the substrate 1, and the substrate 1 is placed in a magnetic field and dispersed by ultrasonic vibration. The magnetic colloidal particles 2 are polarized into magnetic dipoles under the action of the magnetic field, and the magnetic dipoles are arranged in an orderly manner on the substrate 1 through the interaction of the static ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com