Combined suction system for improving periodicity of planar cascade and quality of outlet flow field

A suction system and periodic technology, applied in the field of impeller machinery, can solve problems such as adjustment of suction capacity, inability to guarantee symmetrical suction, and inability to predict suction flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

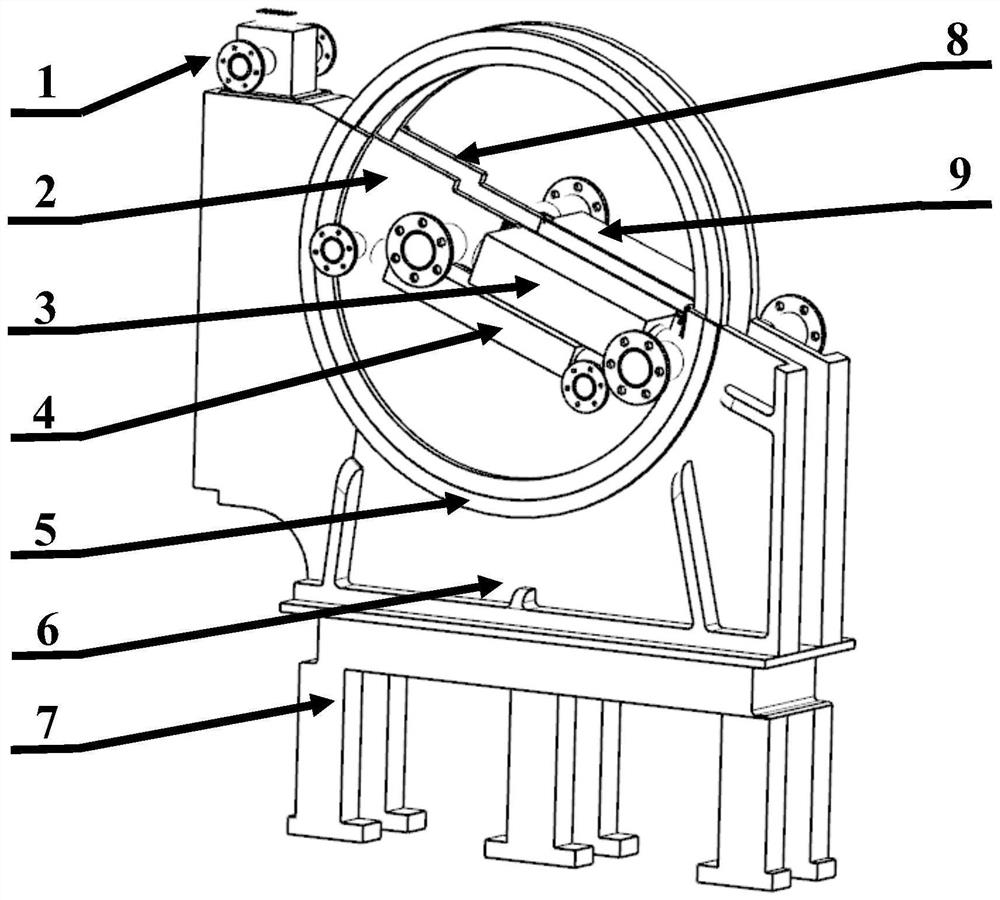

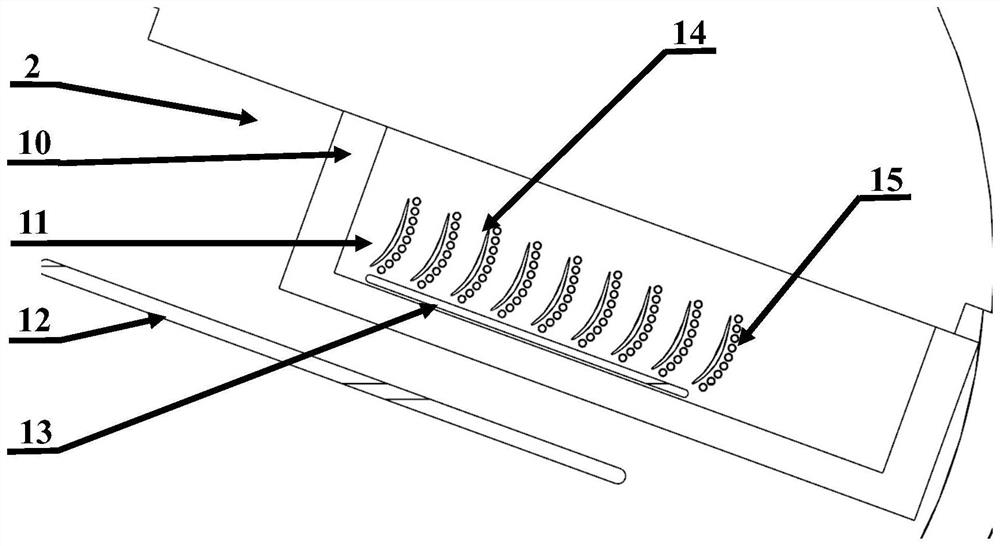

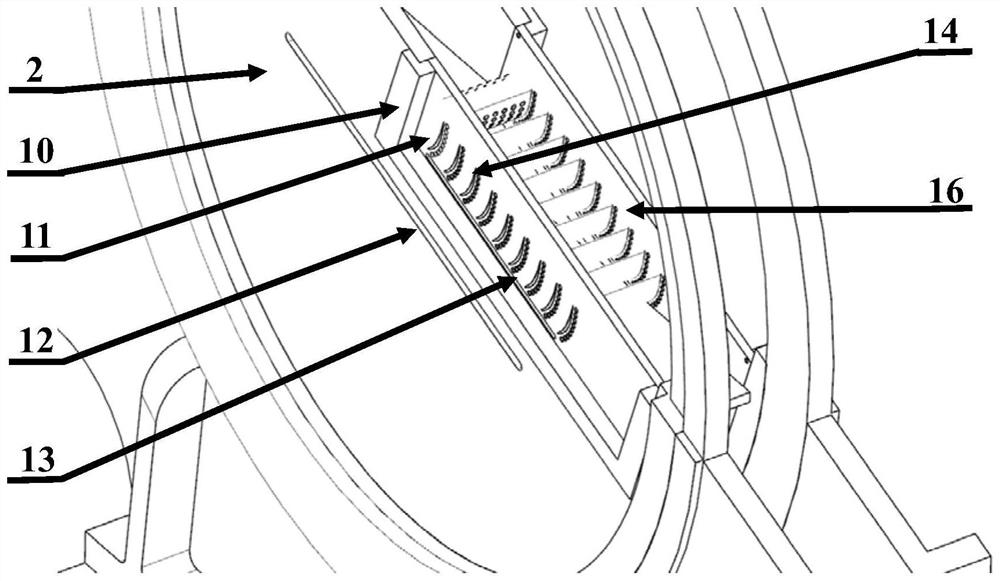

[0074] Such as Figure 1-10 As shown, a combined suction system for improving the periodicity of the plane cascade and the quality of the outlet flow field, including the upper end wall suction chamber 1, the left turntable 2, the left grid suction chamber 3, the left incoming flow Boundary layer suction chamber 4, left turntable slideway 5, cascade wind tunnel test bench 6, cascade wind tunnel test bench fixing seat 7, right turntable 8 and right grid plate suction chamber 9. The structure of the left turntable 2 and the right turntable 8 is the same, it is a semicircular plate structure, symmetrically arranged, and is connected with the left turntable slideway 5 and the right turntable slideway respectively, and the left turntable 2 and the right turntable 8 can be Driven by a motor or manually to rotate in the left turntable slideway 5 and the right turntable slideway; the structure of the left turntable slideway 5 and the right turntable slideway is the same, which is a ri...

Embodiment 2

[0087] According to the specific needs of the experimental situation, different structures and numbers of suction slots 13 at the front edge of the left grid plate and suction slots 13 at the front edge of the right grid plate can be set. The suction slot 13 at the front edge of the side grid and the suction slot at the front edge of the right grid.

[0088] In this embodiment, according to the computational fluid dynamics CFD calculation structure, if the periodicity of the blades in the middle of the cascade is good, the designed length range of the suction slot 13 at the front edge of the left grid plate and the suction slot 13 at the front edge of the right grid plate may not include the middle leaves, such as Figure 11 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com