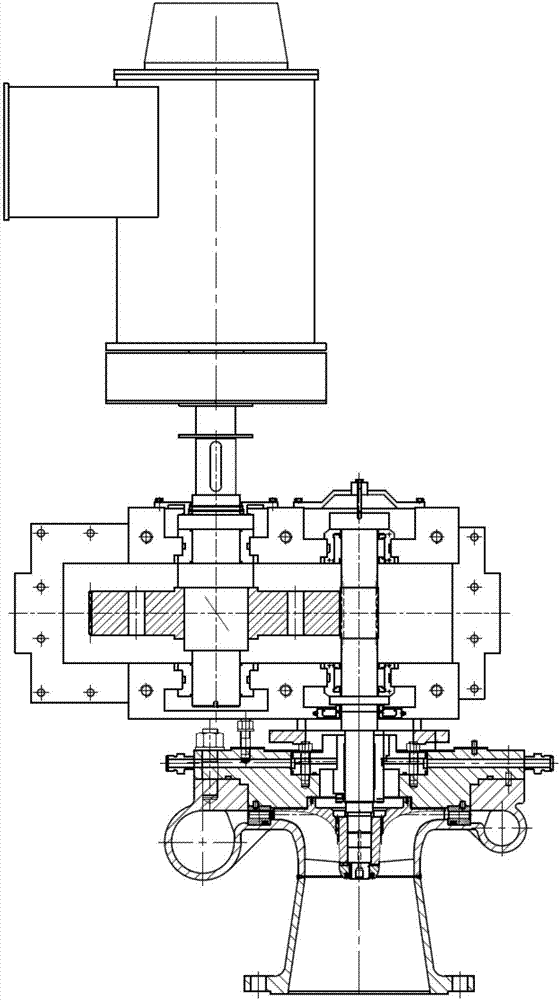

Organic Rankine cycle kilowatt power generation device

A Rankine cycle and power generation device technology, which is applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as large size and complex structure, avoid excitation frequency, avoid external leakage, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

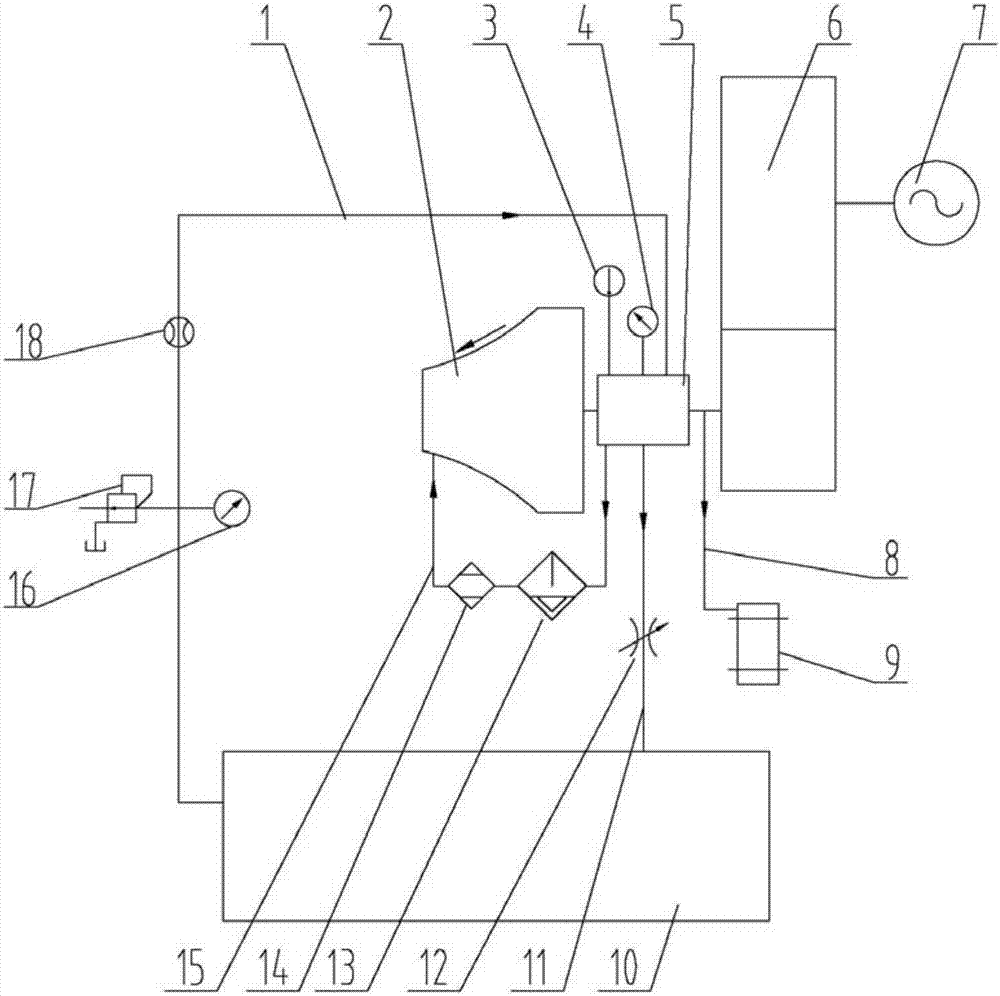

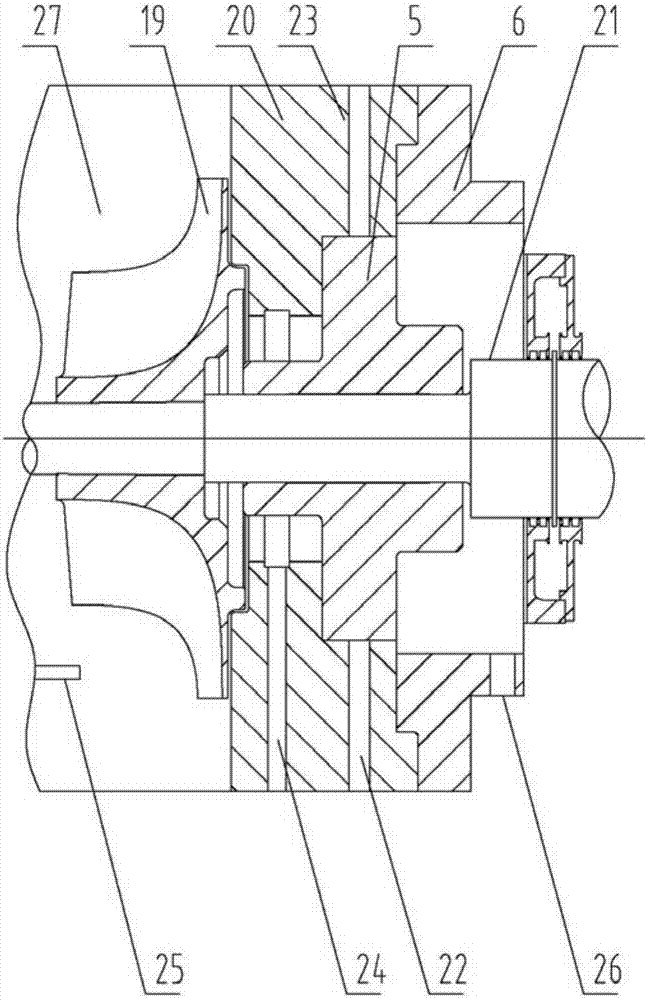

Method used

Image

Examples

Embodiment

[0081] Implementation example: use low-pressure saturated steam at about 130°C in industrial production as heat source, flow rate is 5.4t / h, R245fa is used as working fluid, rated speed is 10676rpm, working fluid inlet temperature is 110°C, and inlet pressure is 1.4Mpa. The designed wheel efficiency of the turbine is 88%, and the efficiency of the output shaft is 80%. After testing under different load conditions, the efficiency of turbine power generation can reach 82%. In the test, the electric power output was successfully realized from no-load to 320kw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com