Water-based anionic polyurethane emulsion as well as preparation method and application

A technology of polyurethane emulsion and anion, which is applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive additives, etc., and can solve problems such as poor bonding strength, poor blending performance, and poor high temperature resistance , to achieve the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

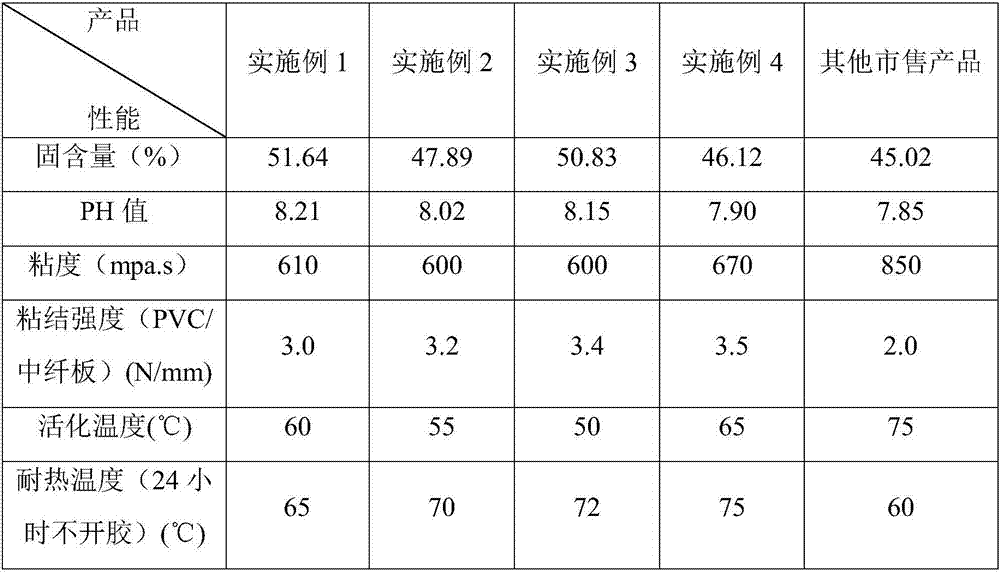

Examples

Embodiment 1

[0051] 1. Preparation of water-based anionic polyurethane emulsion

[0052] Raw material components: 10 parts of pentaerythritol (PE), 39.5 parts of dimethylolpropionic acid A (DMPA), 40 parts of N,N-dimethylformamide (DMF), 0.005 parts of p-toluenesulfonic acid, 200 parts of polyols , 35 parts of TDI, 0.03 parts of stannous octoate, 10 parts of dimethylolpropionic acid B, 5 parts of 1,4-butanediol, 50 parts of N-ethylpyrrolidone, 7.5 parts of triethylamine, 270 parts of deionized water;

[0053] Method: (1) Add 10 parts of pentaerythritol (PE) and 39.5 parts of dimethylolpropionic acid A (DMPA) into a four-neck flask equipped with mechanical stirring, thermometer and condenser, and use 40 parts of N,N-dimethylol Dimethyl formamide (DMF) was used as a solvent, adding 0.005 parts of p-toluenesulfonic acid, slowly raising the temperature to 130°C, and reacting at a constant temperature for 2.5h until the acid value was less than 20mg KOH / g, vacuuming for 1h, removing DMF, and ob...

Embodiment 2

[0063] 1. Preparation of water-based anionic polyurethane emulsion

[0064] Raw material components: 10 parts of pentaerythritol (PE), 49.5 parts of dimethylolpropionic acid A (DMPA), 60 parts of N,N-dimethylformamide (DMF), 0.006 parts of p-toluenesulfonic acid, 245 parts of polyols , TDI 54 parts, stannous octoate 0.04 parts, dimethylolpropionic acid B12.5 parts, 1,6-hexanediol 7 parts, N-ethylpyrrolidone 56 parts, dimethylethanolamine 8.3 parts, deionized water 450 copies;

[0065] Preparation method: (1) Add 10 parts of pentaerythritol (PE) and 49.5 parts of dimethylolpropionic acid A (DMPA) into a four-neck flask equipped with mechanical stirring, thermometer and condenser, and use 60 parts of N,N-di Add methylformamide (DMF) as solvent, add 0.006 parts of p-toluenesulfonic acid, slowly raise the temperature to 135°C, and react at constant temperature for 3 hours until the acid value is less than 20mg KOH / g, vacuumize for 1 hour, remove DMF, and obtain hyperbranched poly...

Embodiment 3

[0074] 1. Preparation of water-based anionic polyurethane emulsion

[0075] Raw material components: 10 parts of pentaerythritol (PE), 59 parts of dimethylolpropionic acid A (DMPA), 70 parts of N,N-dimethylformamide (DMF), 0.009 parts of p-toluenesulfonic acid, 300 parts of polyol , TDI 70 parts, stannous octoate 0.05 parts, dimethylolpropionic acid B16.5 parts, 1,6-hexanediol 10 parts, N-ethylpyrrolidone 60 parts, triethylamine 12.5 parts, deionized water 457 parts share;

[0076] The preparation method is as follows: (1) Add 10 parts of pentaerythritol (PE) and 59 parts of dimethylolpropionic acid A (DMPA) into a four-necked flask equipped with mechanical stirring, a thermometer and a condenser, and use 70 parts of N,N- Dimethylformamide (DMF) was used as a solvent, adding 0.006 parts of p-toluenesulfonic acid, slowly raising the temperature to 145°C, and reacting at a constant temperature for 3 hours until the acid value was less than 20mg KOH / g, vacuuming for 1 hour, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com