Method used for recycling sulfur and nitrogen resources from flue gas and producing hydroxylamine sulphate

A technology of hydroxylamine sulfate and sulfur recovery, applied in the field of environmental protection and chemical engineering, to achieve the effects of reducing production costs, solving the problem of nitrite wastewater, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

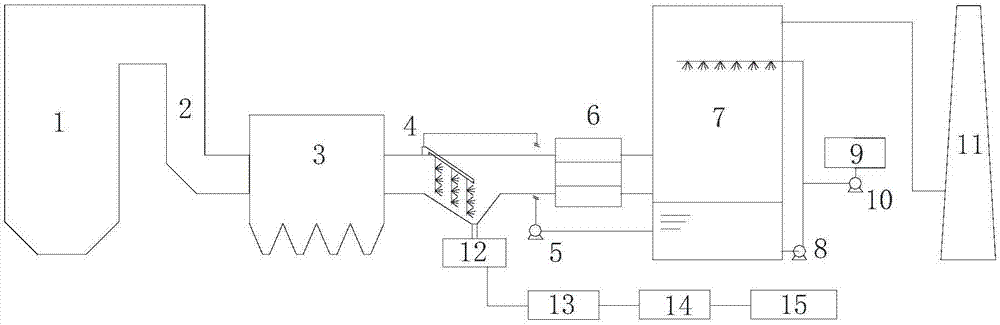

Image

Examples

Embodiment 1

[0051] Based on the method and system of the present invention, the process of flue gas desulfurization and denitrification and sulfur and nitrogen resource reuse is simulated on an experimental simulation device. The flue gas components are as follows: NO is 350ppm, SO 2 500ppm, O 2 It is 5%, the rest is nitrogen, the flue gas temperature is 120°C, and the pressure is 1 atmosphere. Follow H 2 O 2 : The ratio of NO=1:1 is sprayed into hydrogen peroxide. The parameters of the absorption tower are: the absorption tower is a packed tower, and the absorption liquid is 10% Na 2 SO 3 Solution, liquid-gas ratio is 8L / m 3 , PH is controlled at 6.5. SO in the synthesis process of sulfur and nitrogen compounds 2 : NO 2 - The molar ratio is 5:1, the liquid-gas ratio is 3L / m 3 , The pH of the spray liquid is 2.5. The removal efficiency of NO in flue gas after absorption can reach 90%, SO 2 The removal efficiency can reach 99%, and the yield of hydroxylamine sulfate in the absorption solut...

Embodiment 2

[0053] Based on the method and system of the present invention, the process of flue gas desulfurization and denitrification and sulfur and nitrogen resource reuse is simulated on an experimental simulation device. The flue gas components are as follows: NO is 350ppm, SO 2 500ppm, O 2 It is 5%, the rest is nitrogen, the flue gas temperature is 120°C, and the pressure is 1 atmosphere. Follow O 3 : The ratio of NO=1:1 is sprayed into ozone. The parameters of the absorption tower are: the absorption tower is a packed tower, and the absorption liquid is 10% Na 2 SO 3 Solution, liquid-gas ratio is 8L / m 3 , PH is controlled at 6.5. SO in the synthesis process of sulfur and nitrogen compounds 2 : NO 2 - The molar ratio is 5:1, the liquid-gas ratio is 3L / m 3 , The pH of the spray liquid is 2.5. The removal efficiency of NO in flue gas after absorption can reach 90%, SO 2 The removal efficiency can reach 99%, and the yield of hydroxylamine sulfate in the absorption solution can reach 17...

Embodiment 3

[0055] Based on the method and system of the present invention, the process of flue gas desulfurization and denitrification and sulfur and nitrogen resource reuse is simulated on an experimental simulation device. The flue gas components are as follows: NO is 350ppm, SO 2 500ppm, O 2 It is 5%, the rest is nitrogen, the flue gas temperature is 120°C, and the pressure is 1 atmosphere. Follow O 3 : NO = 1:1 ratio is sprayed into ozone. The parameters of the absorption tower are: the absorption tower is a packed tower, and the absorption liquid is 10% Na 2 SO 3 Solution, the liquid-gas ratio is 10L / m 3 , PH is controlled at 6.5. SO in the synthesis process of sulfur and nitrogen compounds 2 : NO 2 - The molar ratio is 5:1, the liquid-gas ratio is 3L / m 3 , The pH of the spray liquid is 2.5. The removal efficiency of NO in flue gas after absorption can reach 95%, SO 2 The removal efficiency can reach 99%, and the yield of hydroxylamine sulfate in the absorption solution can reach 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com