Transient voltage suppressor (TVS) chip and manufacturing method

A technology of transient voltage suppression and manufacturing method, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as the inability to meet the production requirements of high-voltage chips above 400V, and improve anti-surge capability and reliability. , Improve the pressure resistance performance, increase the effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

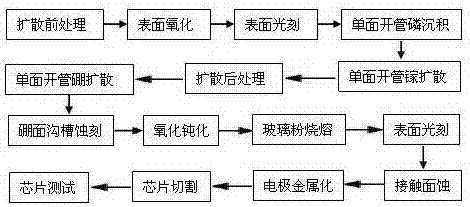

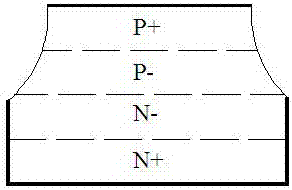

[0023] Embodiment 1: with reference to attached figure 1 and 2 A method for manufacturing a transient voltage suppressor (TVS) chip is further described in detail.

[0024] Pre-diffusion treatment: N-type single crystal silicon wafers are used as raw materials, and the surface of the silicon wafers is chemically treated through acid, alkali, deionized water ultrasonic cleaning and other processes.

[0025] Oxidation: grow a layer of oxide layer on the silicon wafer that has been pre-diffused in an oxidation furnace at 1100-1200 °C.

[0026] Photolithography: Apply gluing, exposure, development, and deoxidation to the oxidized silicon wafer, and engrave a diffusion pattern on the front side in one direction.

[0027] Phosphorus deposition in single-sided open tubes. The single-sided open-tube ammonium dihydrogen phosphate aqueous source deposition process is adopted. The high-purity ammonium dihydrogen phosphate powder is dissolved in deionized water to form an aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com