Processing method for improving tilia bast fiber knitting property

A processing method and technology of linden, applied in the chemical post-processing of fibers, fiber processing, textiles and papermaking, etc., can solve the problems of reduced weaving performance and quality of use, reduced toughness and breaking strength, etc., to enhance the sun resistance performance. , enhance the binding capacity, inhibit the effect of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

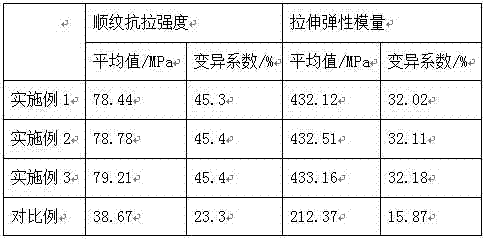

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a kind of processing method of improving the weaving performance of linden hemp, the specific method is as follows:

[0019] (1) Boiling, freezing, steaming and soaking in treatment liquid

[0020] Submerge linseed in water at a temperature of 52°C, boil on high heat, then simmer for 705 seconds, drain and remove, place in a freezer at -18°C for 880 seconds at a constant temperature, and heat up to -1.7°C / min at a heating rate Continue constant temperature freezing at 6°C for 735s, take it out, put it into a steamer at 277°C for constant temperature steam treatment for 795s, cool down to 237°C at a cooling rate of 4.6°C / min and continue constant temperature treatment for 925s, take it out, and immerse it in the treatment solution After 115 minutes, the drained liquid was taken out, and the pretreated linseed was obtained;

[0021] The treatment solution is made of the following raw materials in parts by weight: 21.2 parts of ...

Embodiment 2

[0029] In the embodiment of the present invention, a kind of processing method of improving the weaving performance of linden hemp, the specific method is as follows:

[0030] (1) Boiling, freezing, steaming and soaking in treatment liquid

[0031] Submerge linseed in water at a temperature of 52.5°C, boil on high heat, then simmer for 708 seconds, drain and remove, place in a freezer at -17.5°C for constant temperature freezing for 883 seconds, and raise the temperature to -1.75°C / min. Continue constant temperature freezing at 5.5°C for 738s, take it out, place it in a steamer at 278°C for constant temperature steam treatment for 798s, cool down to 238°C at a cooling rate of 4.7°C / min and continue constant temperature treatment for 928s, take it out, and immerse it in the treatment solution After 118 minutes, the drained liquid was taken out, and the pretreated linseed was obtained;

[0032] The treatment solution is made of the following raw materials in parts by weight: 21...

Embodiment 3

[0037] In the embodiment of the present invention, a kind of processing method of improving the weaving performance of linden hemp, the specific method is as follows:

[0038] (1) Boiling, freezing, steaming and soaking in treatment liquid

[0039] Submerge linseed in water at a temperature of 53°C, boil on high heat, then simmer for 710 seconds, drain and remove, place in a freezer at -17°C for 885 seconds, and heat up to -1.8°C / min at a rate of 1.8°C / min Continue constant temperature freezing at 5°C for 740s, take it out, place it in a steamer at 279°C for constant temperature steam treatment for 800s, cool down to 239°C at a cooling rate of 4.8°C / min and continue constant temperature treatment for 930s, take it out, and immerse it in the treatment solution After 120 minutes, the drained liquid was taken out, and the pretreated linseed was obtained;

[0040] The treatment liquid is made of the following raw materials in parts by weight: 21.6 parts of fresh senna leaves, 26....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com