Preparation method for conductive, anti-corrosive, wear-resistant and high-hardness diamond-like coating layer

A wear-resistant, high-hardness technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problem of high resistance of carbon-based thin film, reduce the number of droplets, improve the quality and performance, The effect of easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Substrates are ultrasonically cleaned in a special solution for 20 minutes, and finally heated and dried with deionized water, alcohol, and a hair dryer;

[0024] Step 2: The substrate is installed on the vacuum equipment turntable, and the rotation speed is adjusted to 2.5r / min;

[0025] Step 3: Close the door of the vacuum equipment and vacuumize; when the pressure of the vacuum chamber reaches 5x10-2Pa, turn on the heater to heat;

[0026] Step 4: When the pressure of the vacuum chamber reaches 1X10-3Pa, the temperature is 50-100 degrees, argon gas is introduced, the ion source ionizes the inert gas, and the surface of the substrate is cleaned and activated with ions, and the current of the ion source is 10-20A;

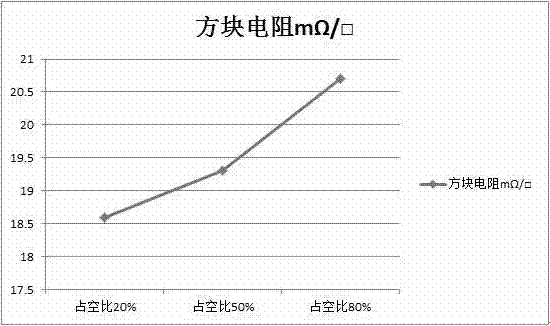

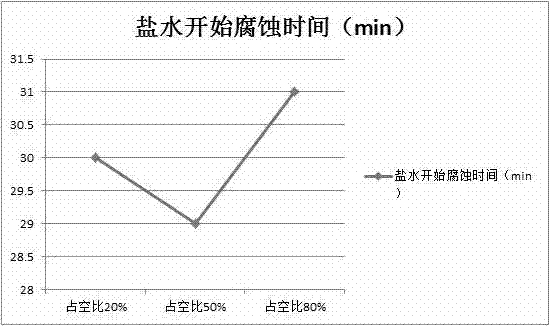

[0027] Step 5: Turn off the ion source, turn on the bias voltage 300V, the duty cycle is 20%, turn on the magnetron target, the magnetron target current is 2-80A, and the titanium transition layer thickness is 200-300nm;

[0028] Step 6: Turn on th...

Embodiment 2

[0033] Step 1: Substrates are ultrasonically cleaned in a special solution for 20 minutes, and finally heated and dried with deionized water, alcohol, and a hair dryer;

[0034] Step 2: The substrate is installed on the vacuum equipment turntable, and the rotation speed is adjusted to 2.5r / min;

[0035] Step 3: Close the door of the vacuum equipment, evacuate, wait for the pressure of the vacuum chamber to be 5x10-2Pa, and turn on the heater to heat;

[0036] Step 4: When the pressure of the vacuum chamber reaches 1X10-3Pa, the temperature is 50-100 degrees, argon gas is introduced, the ion source ionizes the inert gas, and the surface of the substrate is cleaned and activated, and the current is 10-20A;

[0037] Step 5: Turn off the ion source, turn on the bias voltage 300V, the duty cycle is 20%, turn on the magnetron target, the magnetron target current is 10A, and the thickness of the titanium transition layer is 200-300nm;

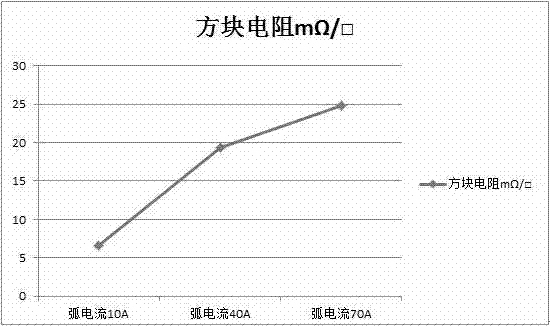

[0038] Step 6: Turn on the ion source, the cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com