PVC/LDPE drug packaging material and preparation method thereof

A packaging material, PVC resin technology, applied in the field of packaging materials, can solve the problems of being easily affected by external conditions, limiting the application of polyvinyl chloride, and easy removal of HCl molecules, etc., to achieve easy industrial scale production, good elasticity, and compatibility excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

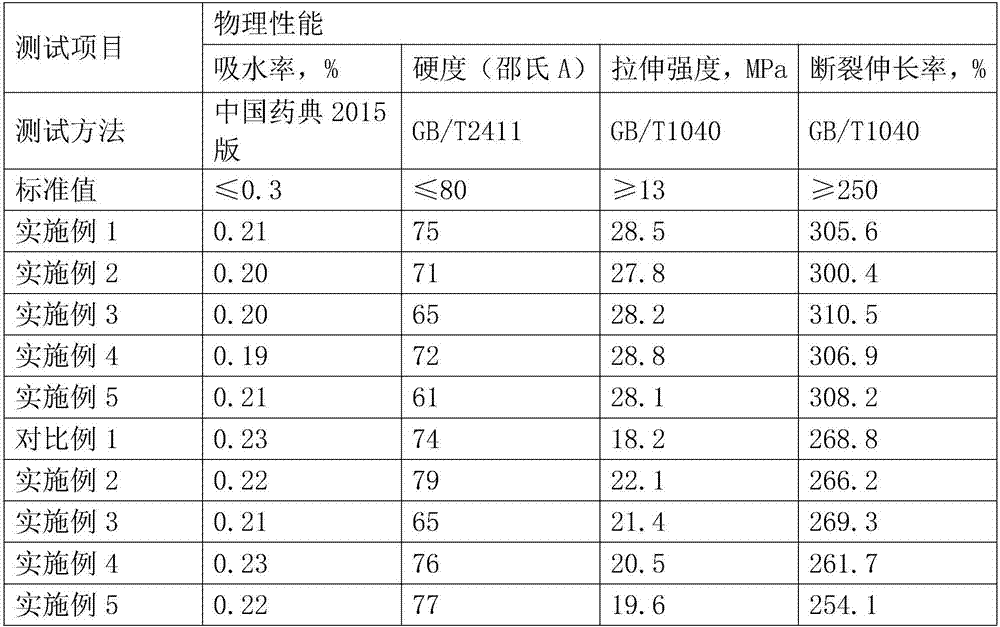

Examples

Embodiment 1

[0025] A PVC / LDPE pharmaceutical packaging material, the parts by weight of raw materials are:

[0026] 80 parts of PVC resin

[0027] LDPE resin 20 parts

[0028] Modified reinforcing material 10 parts

[0029] 20 parts plasticizer

[0030] Trinonylphenyl phosphite 1 part

[0031] Ethylene-vinyl acetate grafted maleic anhydride 3 parts

[0032] Calcium / zinc heat stabilizer 3 parts

[0033] Ethylene-octene copolymer 5 parts

[0034] 10 parts of processing aid

[0035] The PVC resin is a high-polymer PVC resin prepared by a suspension method, the degree of polymerization is 1200, and the residual vinyl chloride content of the resin is less than or equal to 0.5 μg / g.

[0036] The modified reinforcing material is composed of modified glass fiber and modified nano-silica with a mass ratio of 5:2, wherein the modified glass fiber is formed by mixing glass fiber with 20% by weight of surfactant KH560. The nano-silica is made by mixing nano-silica with 8% by weight of surfact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com