A kind of aerobic granular sludge with high denitrification ability at low temperature, cultivation method and cultivation device

An aerobic granular sludge and culture device technology, applied in chemical instruments and methods, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of short start-up time, effluent dissolved organic nitrogen, Ammonia nitrogen and total nitrogen are not up to standard, aerobic granular sludge is easy to disintegrate, etc., to solve the problems of easy disintegration and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

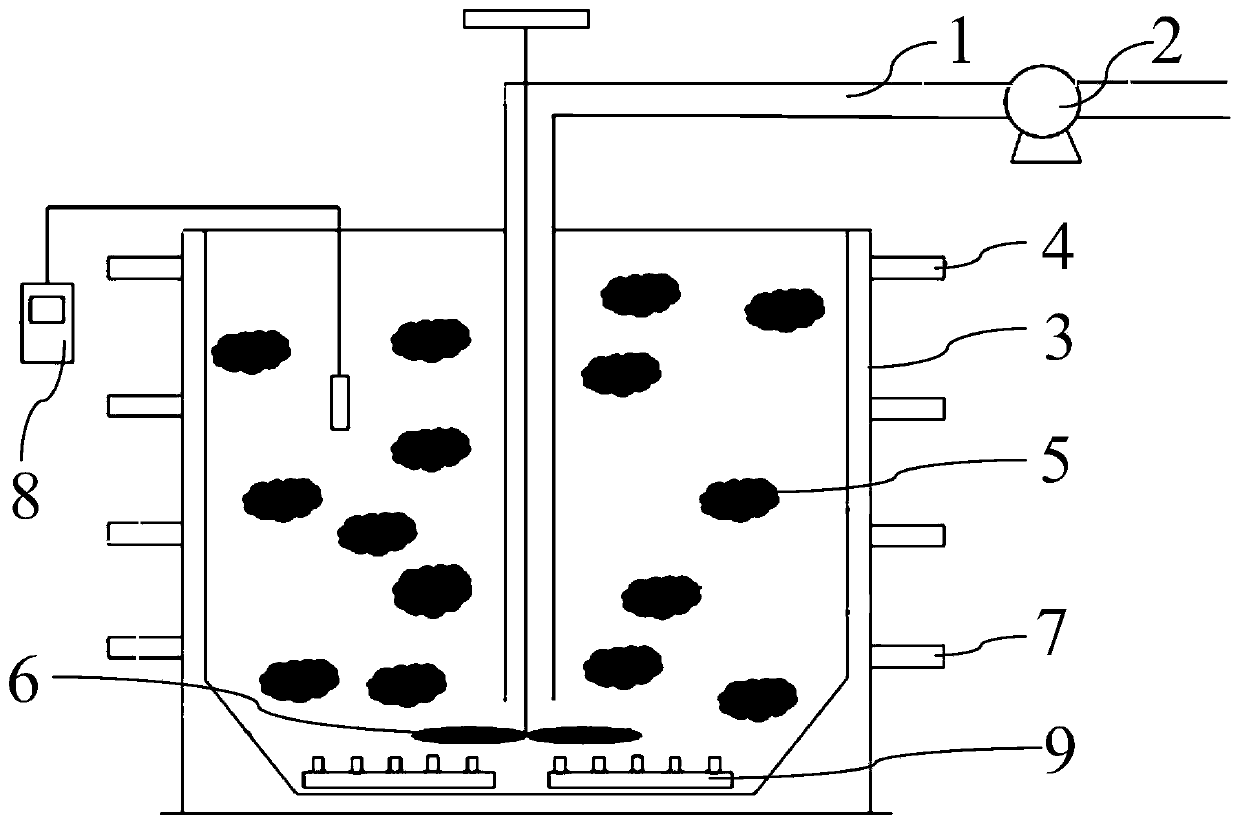

[0049] A method for culturing aerobic granular sludge with high denitrification capacity at low temperature of the present invention, the specific steps are as follows:

[0050] (a) Inoculated flocculent activated sludge was added to the aerobic granular sludge reactors R1, R2 and R3 at a low temperature of 5 °C, and the sludge concentration was 3000 mg / L. After stirring and aeration, the dissolved oxygen concentration It is 5-6mg / L, so that the inoculated flocculent activated sludge can reach a state of complete mixing;

[0051] (b) Add coconut shell biochar to the first reactor R1, rice husk biochar to the second reactor R2, bamboo biochar to the third reactor R3, coconut shell biochar , the concentration of rice husk biochar and bamboo biochar are both 500mg / L, after 24 hours of stirring and aeration, the reactors R1, R2 and R3 are left to stand;

[0052] The first reactor R1 discharges a small amount of coconut shell biochar suspended on the water surface, and adds an org...

Embodiment 2

[0060] In this example, only the inoculated flocculent activated sludge with a sludge concentration of 4000 mg / L was added to the reactor R4, and the inoculated flocculent activated sludge with a sludge concentration of 4000 mg / L was added to the reactor R5 and 1000mg / L rice husk biochar.

[0061](a) Under low temperature conditions of 15°C, inoculate flocculent activated sludge into reactors R4 and R5, the sludge concentration is 4000mg / L, stir and aerate, and the dissolved oxygen concentration is 5-6mg / L, so that The flocculent activated sludge reaches a state of complete mixing;

[0062] (b) Do not add any biochar to the fourth reactor R4, add 1000mg / L rice husk biochar to the fifth reactor R5, after stirring and aerating for 24 hours, let the reactor R4 stand still and R5;

[0063] Add an organic load of 1.6-2.0kg / (m to the fourth reactor R4 3 D) simulated domestic sewage, after stirring and aerating for 24 hours, let the reactor R4 stand still;

[0064] The fifth reac...

Embodiment 3

[0071] In this example, anaerobic granular activated sludge with a sludge concentration of 4000 mg / L was added to reactor R6, and aerobic activated sludge with a sludge concentration of 4000 mg / L and 700 mg / L were added to reactor R7. Rice husk biochar from L.

[0072] (a) At a low temperature of 10°C, add inoculated anaerobic granular activated sludge to the reactor R6, and add inoculated aerobic activated sludge to the reactor R7. The sludge concentration is 4000 mg / L. Stir and Aeration, the dissolved oxygen concentration is 5-6mg / L, so that the activated sludge can be completely mixed;

[0073] (b) No biochar was added to the sixth reactor R6, and only 700 mg / L rice husk biochar was added to the seventh reactor R7. After 24 hours of stirring and aeration, the reaction was left to stand Devices R6 and R7;

[0074] Add organic load 1.6-2.0kg / (m 3 d) simulated domestic sewage, after stirring and aerating for 24 hours, let the reactor R6 stand still;

[0075] The seventh re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com