Underground pipe gallery wireless monitoring system

A comprehensive pipe gallery and wireless monitoring technology, applied in wireless communication, signal transmission system, closed-circuit television system, etc., can solve the problems of large maintenance, large equipment demand, and high construction cost, so as to improve management level and ensure personal safety , Guarantee the effect of operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be described in further detail below in conjunction with examples:

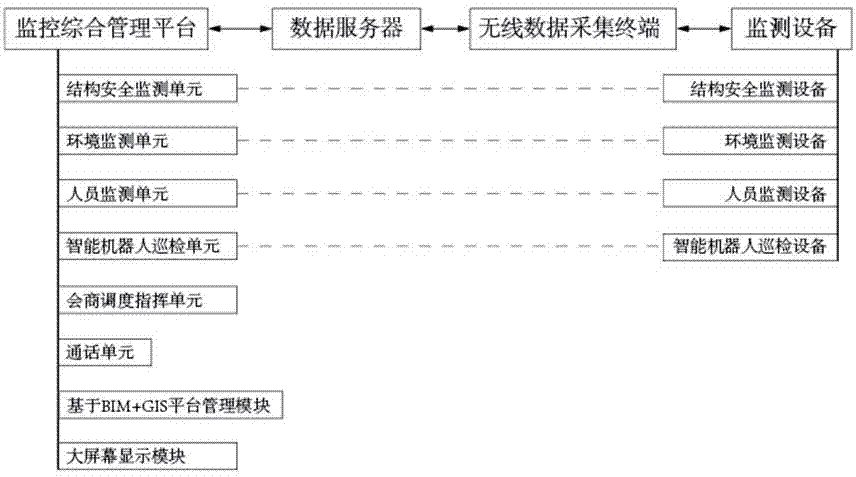

[0022] Such as figure 1 As shown, an integrated pipe gallery wireless monitoring system includes a remote management platform that can sequentially transmit bidirectional data, a data server, a wireless data collection terminal, and monitoring equipment; the remote management platform includes a structural safety monitoring unit, an environmental monitoring unit, and personnel monitoring Unit, intelligent robot inspection unit, consultation dispatch command unit, call unit, management module based on BIM+GIS platform and large-screen display module; the data server mainly collects and stores real-time data and processing results of various units, and performs all business data Allocate storage.

[0023] Wireless data collection terminal: According to the requirements of fire protection regulations, the integrated pipe gallery is divided into an inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com