Infrared detector and preparation method thereof

An infrared detector and structure layer technology, applied in the field of image sensors, can solve the problems of limited compensation capability, poor uniformity, and rising cost, and achieve the effects of improving device integration, improving detection sensitivity, and saving proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art are also covered within the protection scope of the present invention.

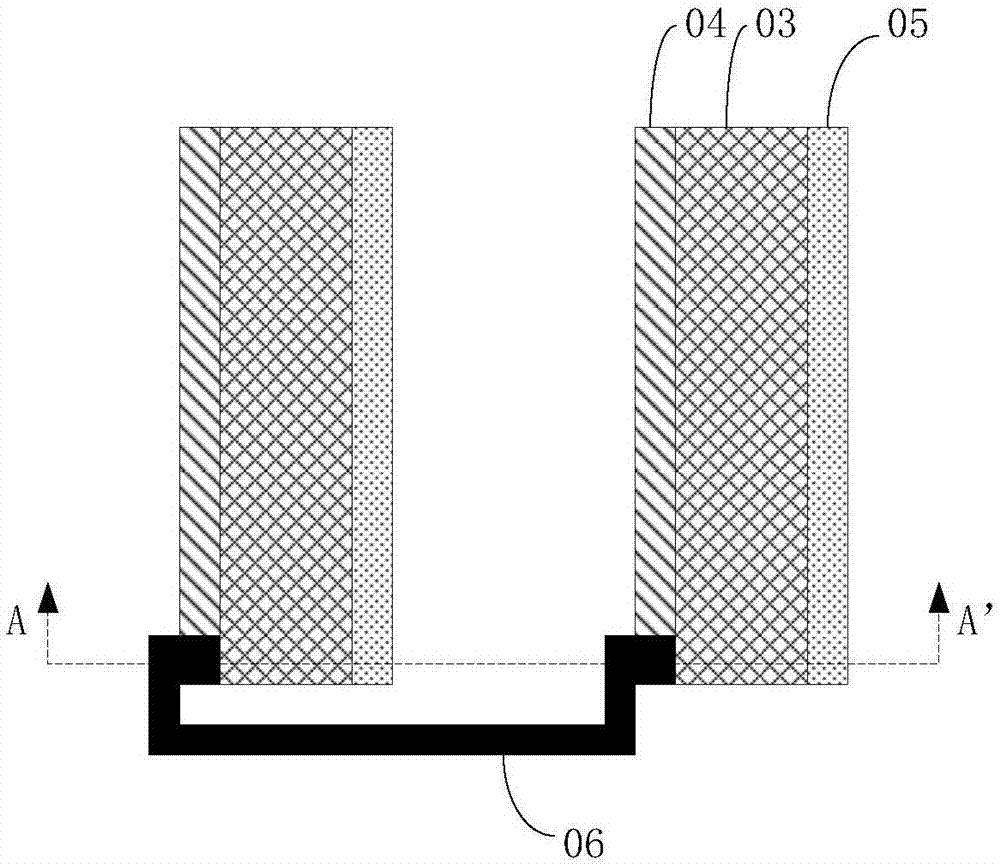

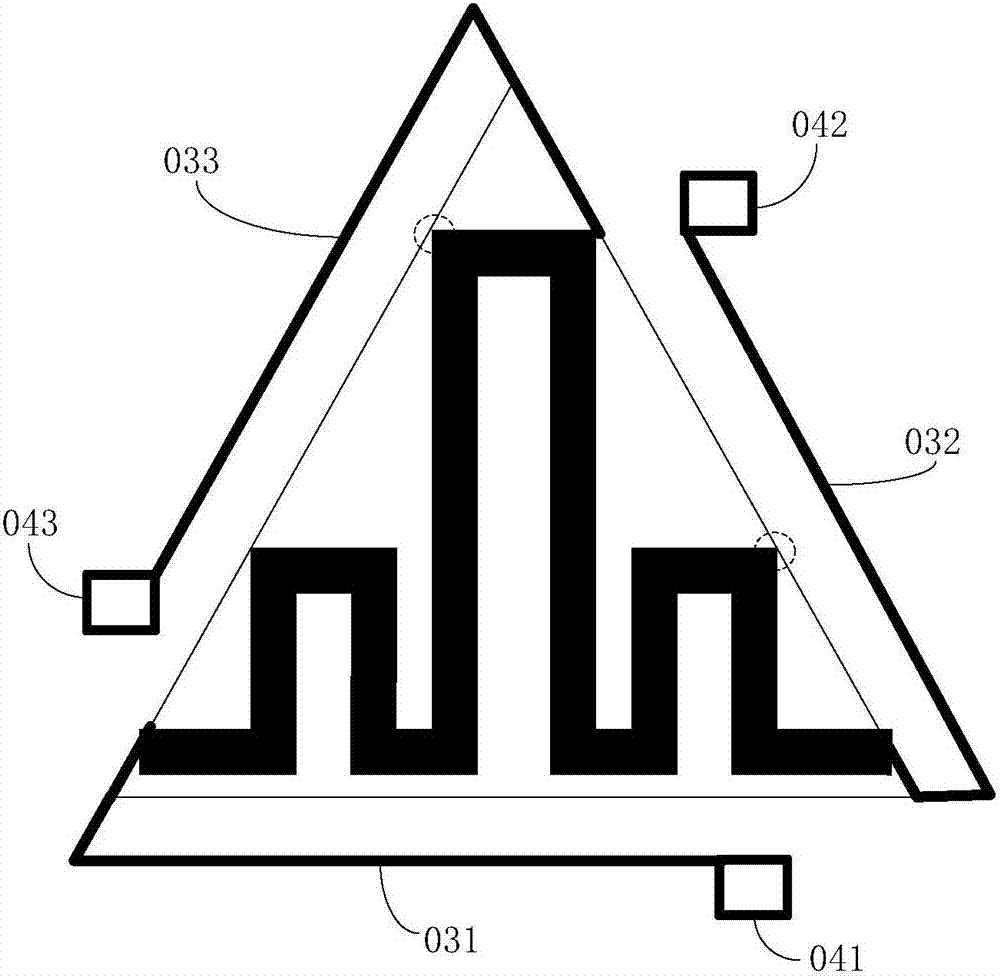

[0045]An infrared detector of the present invention has an effective pixel array, and each effective pixel in the effective pixel array includes a detection structure layer and a blind element structure layer; the detection structure layer and the blind element structure layer are respectively located in a non- doping the two sidewall surfaces of the fin structure.

[0046] In the structural design of the image sensor of the present invention, the design distribution of the existing effective pixel array and the blind pixel array is changed, and the blind pixel arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com