A polyatomic co-doped porous carbon nanosheet electrode material and its preparation method and application

An electrode material and co-doping technology, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of low packing density, slow mass transfer process, and low heteroatom content of porous carbon electrode materials. Good rate performance and cycle stability, simple preparation method, high volume specific capacitance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

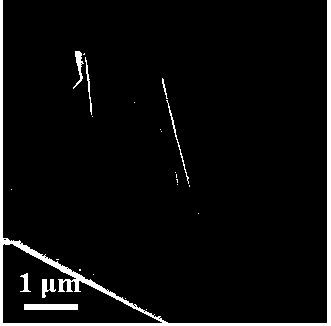

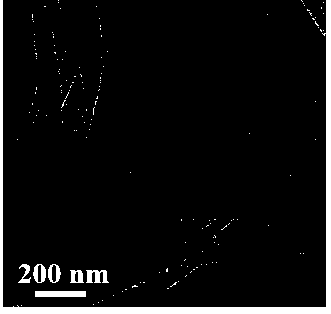

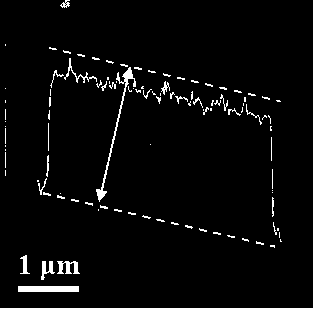

[0032] Put 2 g of fish scales into a polytetrafluoroethylene hydrothermal tank liner filled with 0.6 M KOH aqueous solution, put the shell on, put it in an oven at 80 °C for 24 h, take it out, and absorb the yellow color after cooling to room temperature. Put the transparent solution into a freeze dryer for three days and take it out. Put the freeze-dried solid into a corundum porcelain boat and put it in a high-temperature tube furnace. Under an inert atmosphere, heat at 2.5 °C min -1 Heated at a heating rate of 600 °C and held for 1 h; after the tube furnace dropped to room temperature, the product in the corundum porcelain boat was taken out, washed with deionized water until neutral, and then dried in an oven at 80 °C to obtain multi- Atomically co-doped porous carbon nanosheet electrode materials (such as figure 1 ). Its specific surface area is 962 m 2 g -1 , the pore volume is 0.41 cm 3g -1 , the oxygen content is 14.64%, the nitrogen content is 5.05%, the sulfur ...

Embodiment 2

[0036] The operating conditions are the same as in Example 1, except that the carbonization temperature is 700 °C. The obtained polyatomic co-doped porous carbon nanosheet electrode material. Its specific surface area is 1637 m 2 g -1 , the pore volume is 0.72 cm 3 g -1 , the oxygen content is 13.05%, the nitrogen content is 3.41%, the sulfur content is 0.68%, and the sheet thickness is about 5 nm.

[0037] The same method as in Example 1 was used for electrochemical testing, and the results showed that the mass specific capacitances calculated by the constant current charge and discharge test were: 554, 337, 323, 296, 277, 266, 255, 248, 241, 235 、224 F g -1 , the volume specific capacitances are: 456, 277, 266, 244, 228, 219, 210, 204, 198, 193, 184 F cm -3 . at current densities from 1 Ag -1 increased to 200 A g -1 , the capacity retention rate is 75.7%. at 5 A g -1 The specific capacitance still maintains 93.7% after 10000 cycles under the current density.

Embodiment 3

[0039] The operating conditions are the same as in Example 1, except that the carbonization heating rate is 10 °C / min. The obtained polyatomic co-doped porous carbon nanosheet electrode material. Its specific surface area is 1224 m 2 g -1 , the pore volume is 0.52 cm 3 g -1 , the oxygen content is 13.45%, the nitrogen content is 4.14%, the sulfur content is 0.81%, and the sheet thickness is about 4 nm.

[0040] The same method as in Example 1 was used for electrochemical testing, and the results showed that the mass specific capacitances obtained through constant current charge and discharge tests were: 511, 367, 295, 289, 272, 263, 255, 241, 236, 230 、224F g -1 ;Volume specific capacities are: 501, 360, 283, 275, 267, 258, 250, 236, 231, 225, 220 F cm -3 , at current densities from 1 A g -1 increased to 200 A g -1 , the capacity retention rate is 77.4%. at 5 A g -1 The specific capacitance still maintains 94.2% after 10000 cycles under the current density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com