Anisotropic heat-conducting nylon 6/graphene nanocomposite material and preparation method thereof

A nano-composite material and anisotropic technology, applied in the field of composite materials, can solve the problems of poor compatibility between graphene and silicone rubber, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

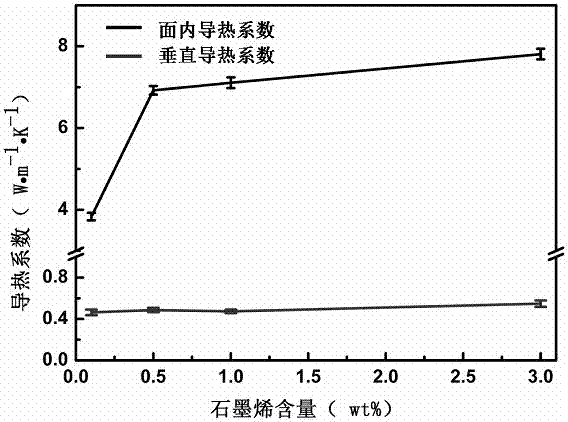

[0023] Embodiment 1: the preparation method of a kind of anisotropic thermally conductive nylon 6 / graphene nanocomposite material of the present embodiment, comprises the following steps:

[0024] 1. Preparation of nylon 6 / graphene masterbatch: Add graphene and nylon 6 into the torque rheometer according to the formula with graphene mass fraction of 10%, at a temperature of 210-230°C at a speed of 40-45rpm Melting and blending for 5-10 minutes; then extruding through a parallel twin-screw extrusion device, and shearing with a shearing machine to obtain a masterbatch of nylon 6 / graphene.

[0025] 2. Preparation of nylon 6 / graphene nanocomposite material: get 1 part of nylon 6 / graphene masterbatch prepared by step (1), mix it with 99 parts by weight of nylon 6 and add it to the torque rheometer, and at 210-230 Melting and blending at a temperature of 40-45 rpm for 5-10 min at a temperature of °C to prepare a nylon 6 / graphene composite material with a mass content of 0.1 wt%.

...

Embodiment 2

[0029] A kind of preparation method of the nylon 6 / graphene nano-composite material of anisotropic heat conduction of the present embodiment, comprises the following steps:

[0030] 1. To prepare nylon 6 / graphene masterbatch, add graphene and nylon 6 to the torque rheometer according to the formula with a graphene mass fraction of 10%, at a temperature of 210-230°C at a speed of 40-45rpm Melting and blending for 5-10 minutes; then extruding through a parallel twin-screw extrusion device, and shearing with a shearing machine to obtain a masterbatch of nylon 6 / graphene.

[0031] 2. Preparation of nylon 6 / graphene nanocomposite material: get 5 parts of nylon 6 / graphene masterbatches prepared by step (1), mix with nylon 6 of 95 parts by weight and add in the torque rheometer, at 210-230 Melting and blending at a temperature of 40-45 rpm for 5-10 minutes at a temperature of °C to prepare a nylon 6 / graphene composite material with a mass content of 0.5 wt%.

[0032] 3. Put the drie...

Embodiment 3

[0034] Embodiment three: the preparation method of a kind of anisotropic thermally conductive nylon 6 / graphene nanocomposite material of the present embodiment, comprises the following steps:

[0035] 1. Preparation of nylon 6 / graphene masterbatch: Add graphene and nylon 6 into the torque rheometer according to the formula with graphene mass fraction of 10%, at a temperature of 210-230°C at a speed of 40-45rpm Melting and blending for 5-10 minutes; then extruding through a parallel twin-screw extrusion device, and shearing with a shearing machine to obtain a masterbatch of nylon 6 / graphene.

[0036] 2. prepare nylon 6 / graphene nanocomposite material: get the nylon 6 / graphene masterbatch that 10 parts of steps (1) prepare, mix and add in the torque rheometer with the nylon 6 of 90 parts by weight fractions, at 210-230 Melting and blending at a temperature of 40-45 rpm for 5-10 min at a temperature of °C to prepare a nylon 6 / graphene composite material with a mass content of 1 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com