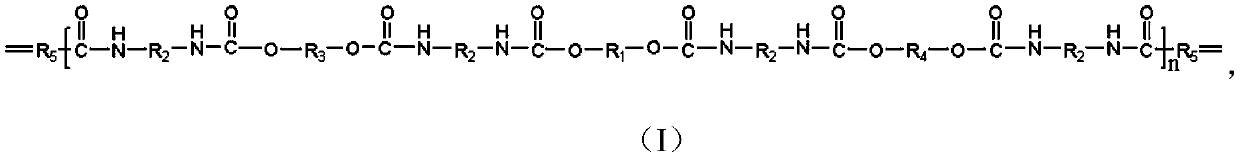

A modified polyurethane oligomer, its preparation method and its application in photocuring digital inkjet printing

A digital inkjet printing and oligomer technology, applied in application, ink, dyeing, etc., can solve the problems of products with irritating odor, numerous preparation steps, toxicity and risks, etc., achieve complete photocuring reaction and reduce pH sensitivity The effect of high stability, solid content and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

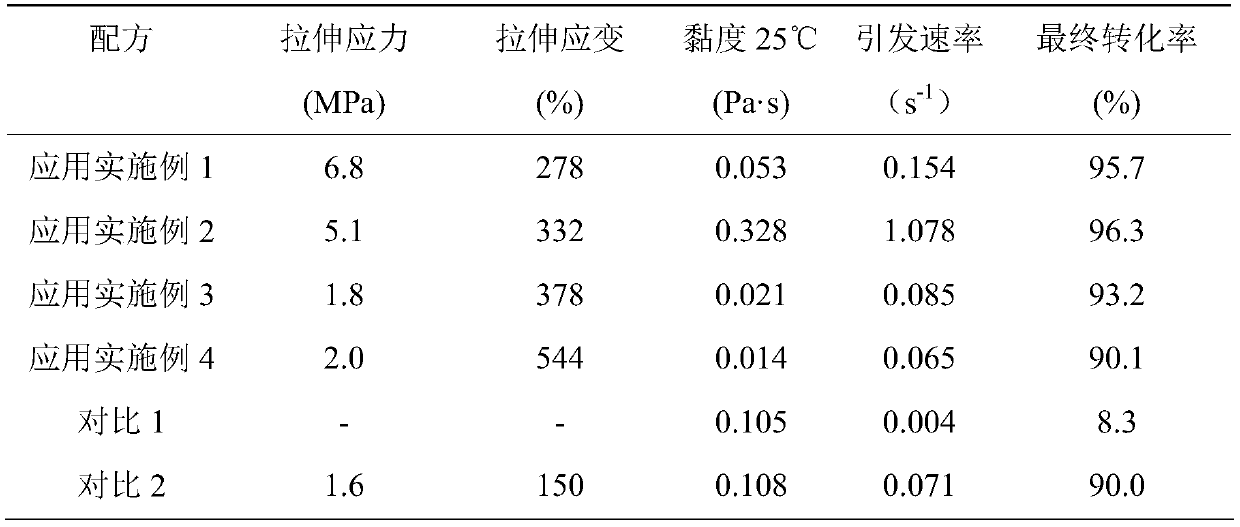

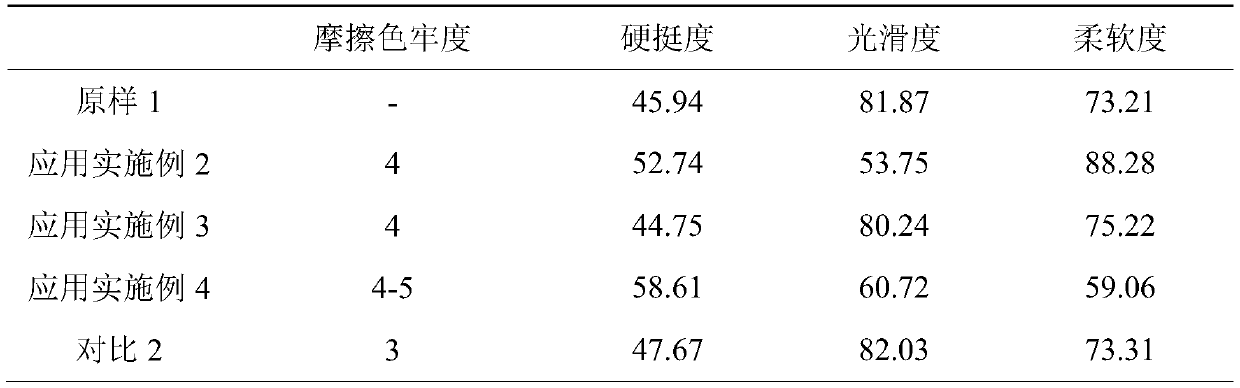

Embodiment 1

[0036] After all the raw materials were dehydrated and dried, 35.30 mmol of isophorone diisocyanate was added to a four-necked flask, and then 10 mmol of polypropylene glycol with a molecular weight of 800 was placed in a constant pressure dropping funnel at 0.3 drops / second (hereinafter referred to as Be dripped in the flask at the speed of d / s), control stirring speed at about 350r / min, N 2 The reaction was carried out at 80°C for 4h under the protection of the atmosphere. continue at N 2 The temperature was lowered to 70°C under atmosphere protection, and starvation feeding method was used to drop 10.50mmol of N-methylethylene glycol amine diluted with 3ml of acetone at a rate of 0.2d / s. After reacting for 0.5h, 7.55mmol of 1 was added dropwise. 4-butanediol reacted for 3 hours to extend the chain, pay attention to the change of system viscosity and rotational speed, until the NCO value dropped to the theoretical value of 2.90%. Subsequently, 14.63 mmol of hydroxyethyl me...

Embodiment 2

[0039] After all raw materials have been dehydrated and dried, 34.55 mmol of hexamethylene diisocyanate is added to a four-necked flask, and 10 mmol of polyethylene glycol with a molecular weight of 2000 is placed in a constant pressure dropping funnel, and the 0.3 d / s The speed is added dropwise in the flask, and the stirring speed is controlled at about 350r / min, N 2 The reaction was carried out at 80°C for 4h under the protection of the atmosphere. continue at N 2 The temperature was lowered to 65°C under the protection of the atmosphere, and starvation feeding method was adopted, and 10.50mmol of N-methylethylene glycol amine diluted with 3ml of acetone was added dropwise at a rate of 0.2d / s. After reacting for 0.5h, 11.60mmol of 1 was added dropwise. 4-butanediol reacted for 4 hours to extend the chain, pay attention to the change of system viscosity and rotational speed until the NCO value dropped to the theoretical value of 1.25%. Subsequently, 6.42 mmol of hydroxyeth...

Embodiment 3

[0042] After all raw materials have been dehydrated and dried, 31.56mmol of 4,4-diisocyanate dicyclohexylmethane was added to a four-necked flask, and 10mmol of polytetrahydrofuran with a molecular weight of 1200 was placed in a constant pressure dropping funnel, 0.3d / s speed into the flask, control the stirring speed at about 350r / min, N 2 The reaction was carried out at 80°C for 2h under the protection of the atmosphere. continue at N 2 The temperature was lowered to 65°C under atmosphere protection, and starvation feeding method was used to drop 10.50mmol of N-phenylethylene glycol amine diluted with 3ml of acetone at a rate of 0.2d / s. After reacting for 0.5h, 4.44mmol of 1 was added dropwise. 4-butanediol reacted for 2 hours to extend the chain, pay attention to the change of system viscosity and rotational speed until the NCO value dropped to the theoretical value of 4.30%. Subsequently, 20.05 mmol of hydroxyethyl methacrylate was added as an active end-capping agent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com