Preparation method of low crystalline, mildew-proof and water-resistant urea resin

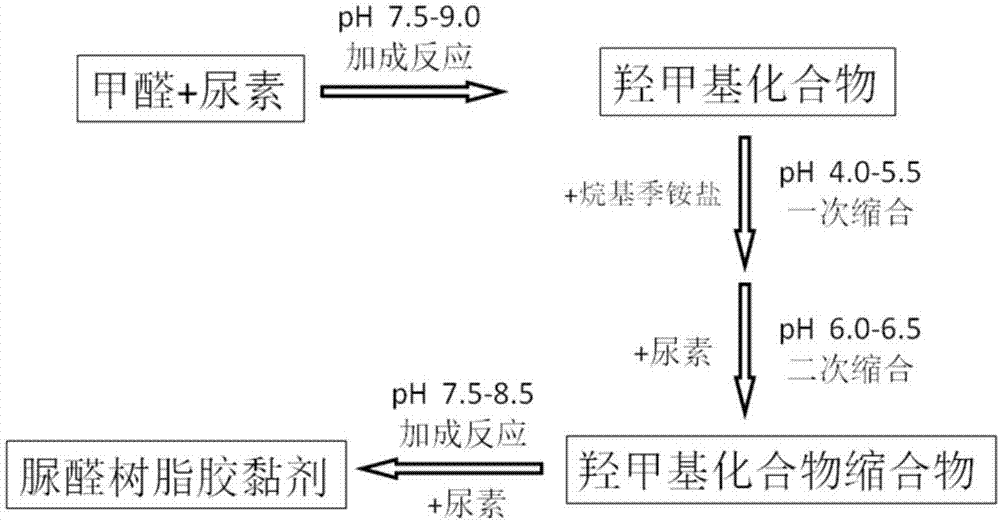

A urea-formaldehyde resin, low crystallization technology, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesive additives, etc., can solve crystallization, affect adhesive water resistance and bonding strength, affect adhesive The uniformity of adhesive bonding and other issues can be solved, and the preparation process is simple, the aggregation probability of urea-formaldehyde resin colloidal particles is reduced, and the effect of easy operation is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

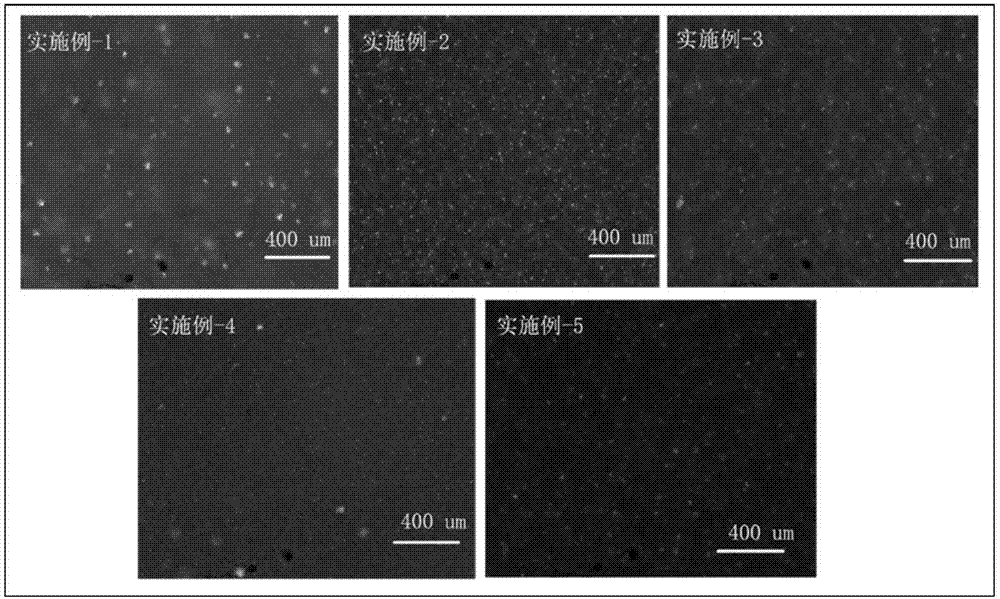

Embodiment 1

[0026] (1) Add 100 parts by weight of formaldehyde solution (concentration is 37%), urea of 30 parts by weight in 500mL flask; Regulate system with aqueous sodium hydroxide solution (concentration is 20%) or sodium carbonate solution (concentration is 20%) The pH value is 7.5, after incubating in a water bath at 65°C for 30 minutes, slowly raise the temperature of the water bath to 85°C, and incubate for 30 minutes;

[0027] (2) Add the cetyltrimethylammonium bromide of 0.5% formaldehyde aqueous solution weight part to reaction system, regulate the pH value of reaction system to 4.0 with formic acid aqueous solution (concentration is 20%) simultaneously, measure once every 10 minutes Cloud point, when the sample is dripped into room temperature water and is in the form of white clouds, adjust the pH value of the reaction system to 6.0 with aqueous sodium hydroxide solution (concentration is 20%) or aqueous sodium carbonate solution (concentration is 20%), and drop into 12 par...

Embodiment 2

[0030] (1) Add 100 parts by weight of formaldehyde aqueous solution (concentration is 37%), urea of 30 parts by weight in the 500mL flask; Regulate system pH value with aqueous sodium hydroxide solution or sodium carbonate aqueous solution to be 9.0, insulate in 75 ℃ of water baths 30 Minutes later, the temperature of the water bath was slowly raised to 92°C and kept for 60 minutes;

[0031] (2) Add the cetyltrimethylammonium bromide of 5.0% formaldehyde aqueous solution weight part to reaction system, regulate the pH value of reaction system to 5.5 with formic acid aqueous solution (concentration is 20%) simultaneously, measure once every 10 minutes Cloud point, when sampling is dripped into the water and is white cloud, adjust the pH value of reaction system with aqueous sodium hydroxide solution (concentration is 20%) or sodium carbonate aqueous solution (concentration is 20%) to be 6.5, drop into 18 parts by weight of urea; 45 minutes;

[0032] (3) Cool the reaction sys...

Embodiment 3

[0034] (1) Add 100 parts by weight of formaldehyde aqueous solution (concentration is 37%), 33 parts by weight of urea in a 500mL flask; adjust the pH value of the system to 8.5 with aqueous sodium hydroxide or sodium carbonate aqueous solution, and incubate in a water bath at 70°C for 30 Minutes later, the temperature of the water bath was slowly raised to 88°C and kept for 40 minutes;

[0035] (2) Add the cetyltrimethylammonium bromide of 2.5% formaldehyde aqueous solution weight part to reaction system, regulate the pH value of reaction system to 4.5 with formic acid aqueous solution (concentration is 20%) simultaneously, measure once every 10 minutes Cloud point, when sampling is dripped into water and is white cloud, adjust the pH value of the reaction system with aqueous sodium hydroxide solution (concentration is 20%) or sodium carbonate aqueous solution (concentration is 20%) to be 6.3, drop into 14 parts by weight of urea; 35 minutes;

[0036] (3) Cool the reaction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com