Method for preparing cristobalite micropowder from melted quartz crucibles used during polycrystalline silicon ingot casting

A technology of fused silica and cristobalite, applied in the field of preparation of cristobalite micropowder, can solve the problems of long production time, high labor cost, inability to meet the requirements, and achieve the effects of improving efficiency, reducing labor cost and solving waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

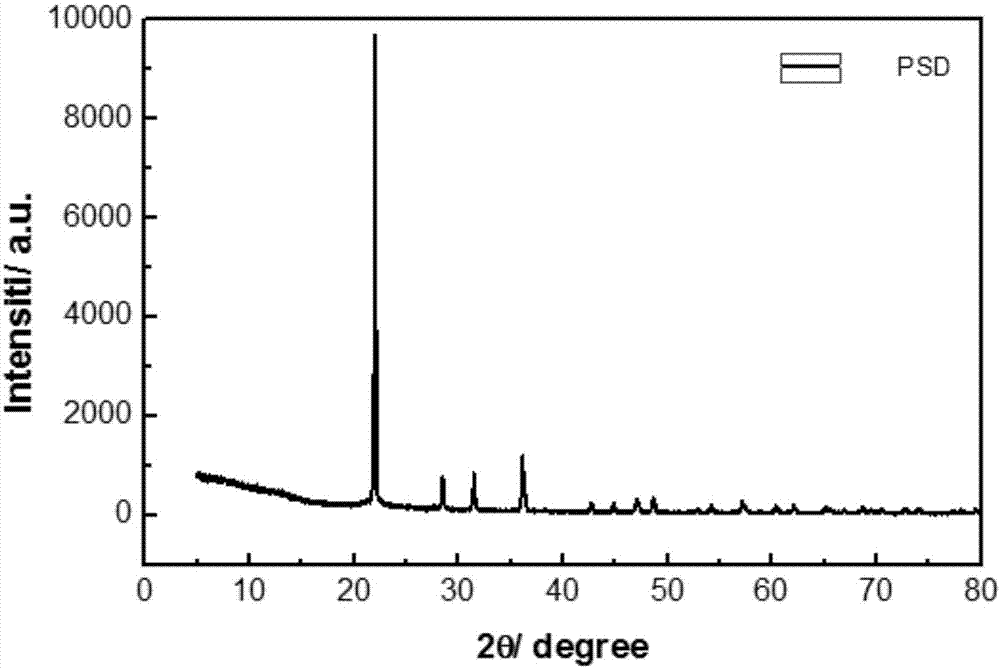

[0025] Cristobalite micropowder, the raw material is fused silica crucible, through physical treatment, the particle size distribution is 800 mesh, SiO 2 Ultrafine cristobalite powder with a content greater than 99.2%.

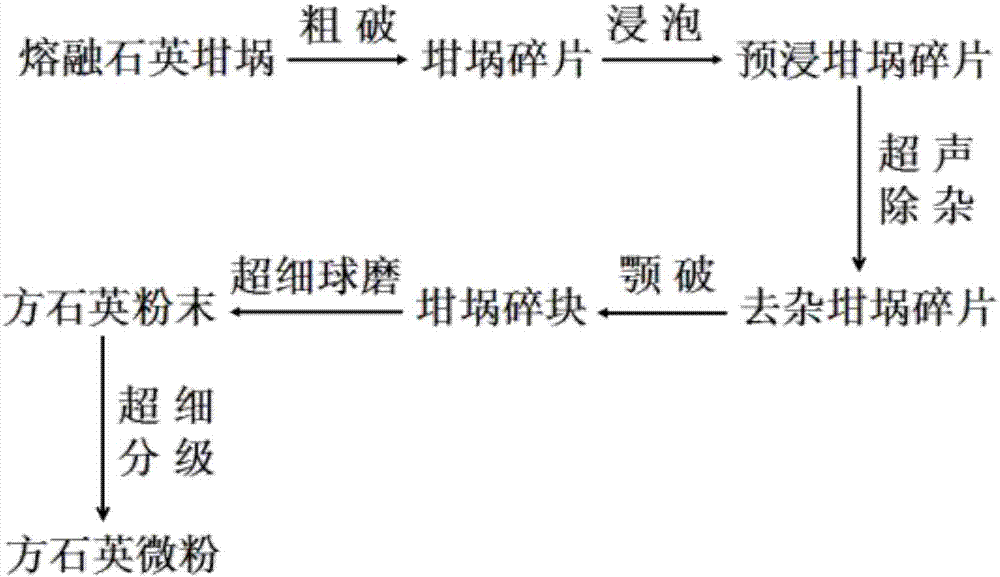

[0026] refer to figure 1 , a process for preparing ultrafine quartz powder using a fused silica crucible after polysilicon ingot casting in this embodiment includes the following steps:

[0027] 1. Use an industrial-grade impact drill to break a large piece of fused silica crucible into 15-30cm crucible fragments;

[0028] 2. Put the crucible fragments into the water pool and soak for 12 hours;

[0029] 3. Put the crucible fragments into the ultrasonic cleaner for 30 minutes;

[0030] 4. Put the crucible fragments into the compound pendulum jaw crusher for secondary fine crushing, and crush them into crucible fragments with a particle size of 2 to 5 cm;

[0031] 5. Using ultra-fine powder technology, the crucible fragments are ground into cristobalite powd...

Embodiment 2

[0034] Ultrafine cristobalite powder, the raw material is fused silica crucible, through physical treatment, the particle size distribution is 2000 mesh, SiO 2 Ultrafine cristobalite powder with a content greater than 99.5%.

[0035] 1. Use an industrial-grade industrial-grade impact drill pick to break a large piece of fused silica crucible into 15-30cm crucible fragments;

[0036] 2. Soak the crucible fragments in weak acid solution for 6 hours;

[0037] 3. Put the crucible fragments into the ultrasonic cleaner for 30 minutes;

[0038] 4. Put the crucible fragments into the compound pendulum jaw crusher for secondary fine crushing, and crush them into crucible fragments with a particle size of 2 to 5 cm;

[0039] 5. Using ultra-fine powder technology, the crucible fragments are ground into cristobalite powder with a particle size of less than 10 microns in a built-in reverse rotary ball mill;

[0040] 6. Use an ultra-fine powder classifier to classify the quartz powder, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com