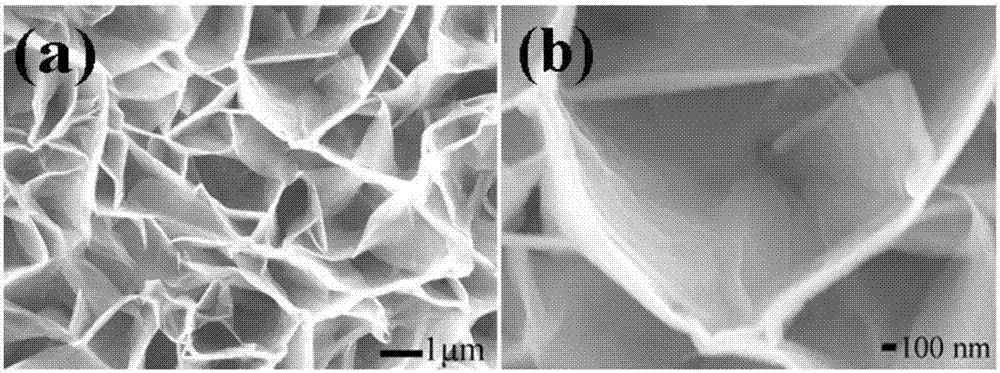

Preparation method of honeycomb-shaped zinc oxide nanowall array

A zinc oxide nano- and honeycomb-shaped technology, applied in the field of photocatalysis, can solve problems such as limiting the practical application of zinc oxide nano-array structures, high cost, and complicated operation, and achieve good photocatalytic performance, low cost, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Cut the aluminum foil into a suitable shape, and then use acetone, alcohol, and deionized water for ultrasonic cleaning;

[0023] (2) Use oxygen with a flow rate of 5SCCM and argon with a flow rate of 40SCCM as the reaction gas, at a pressure of 5*10 -1 Pa, under the condition of 40W power, prepare zinc oxide seed layer on aluminum foil substrate, and the coating time is 10min;

[0024] (3) Put the seed layer-plated substrate obtained in step (2) in a mixed solution of zinc nitrate and hexamethylenetetramine (molar ratio 1:1) for hydrothermal reaction at a temperature of 95°C and water The thermal growth time is 3h, and the honeycomb zinc oxide nanowall array is obtained;

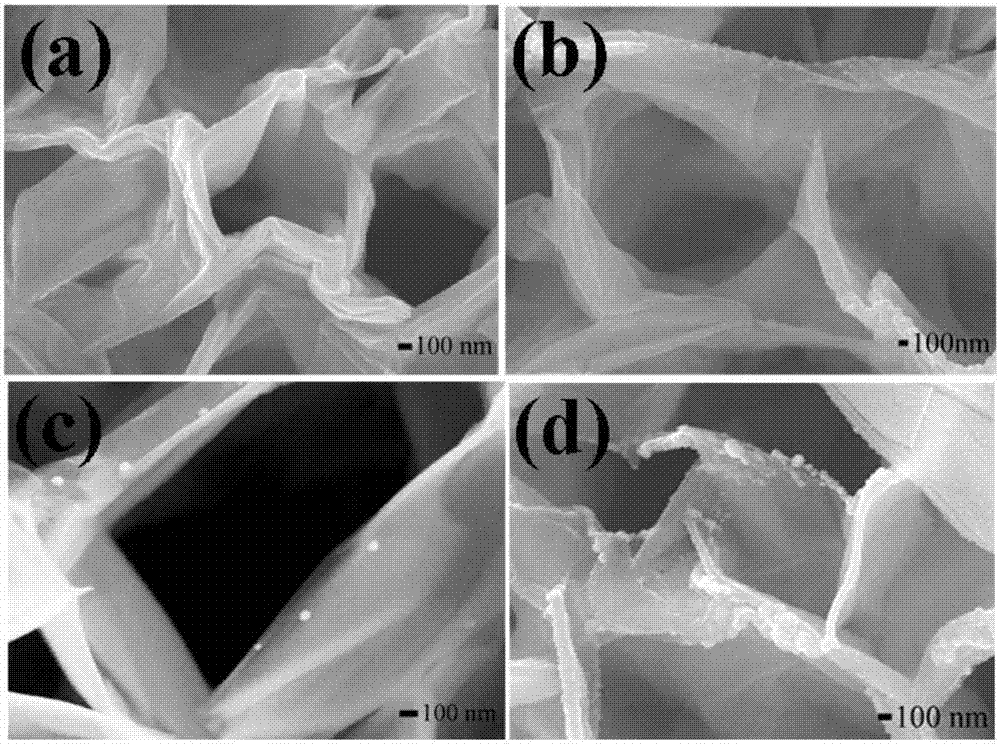

[0025] (4) Perform DC sputtering silver plating on the resultant of step (3), under the condition that the flow rate is 40SCCM argon gas, the power is 40W, and the sputtering is 45s, so that a layer of Ag nanoparticles is deposited on the surface of the resultant;

[0026] (5) Subjecting the resultant in...

Embodiment 2

[0030] (1) Cut the aluminum foil into a suitable shape, and then use acetone, alcohol, and deionized water for ultrasonic cleaning;

[0031] (2) Using oxygen with a flow rate of 10 SCCM and argon with a flow rate of 50 SCCM as the reaction gas, under the conditions of a pressure of 1.0 Pa and a power of 70 W, a zinc oxide seed layer was prepared on the aluminum foil substrate, and the coating time was 10 minutes;

[0032] (3) Put the seed layer-plated substrate obtained in step (2) in a mixed solution of zinc nitrate and hexamethylenetetramine (molar ratio 1:1) for hydrothermal reaction at a temperature of 95°C and water The thermal growth time is 4h, and the honeycomb-shaped zinc oxide nanowall array is obtained;

[0033] (4) Perform DC sputtering silver plating on the resultant of step (3), under the condition that the flow rate is 10SCCM argon gas, the power is 20W, and the sputtering is 45s to deposit a layer of Ag nanoparticles on the surface;

[0034] (5) Subjecting the resultan...

Embodiment 3

[0038] (1) Cut the aluminum foil into a suitable shape, and then use acetone, alcohol, and deionized water for ultrasonic cleaning;

[0039] (2) Using oxygen with a flow rate of 10 SCCM and argon with a flow rate of 50 SCCM as the reaction gas, under the conditions of a pressure of 1.0 Pa and a power of 70 W, a zinc oxide seed layer was prepared on the aluminum foil substrate, and the coating time was 10 minutes;

[0040] (3) Put the substrate coated with the seed layer in (2) in a mixed solution of zinc nitrate and hexamethylenetetramine (molar ratio 1:1), the temperature of the hydrothermal method is 95℃, and the time of hydrothermal growth is 4h to obtain a honeycomb-shaped zinc oxide nanowall array;

[0041] (4) The conditions for the sample in (3) to be silver-plated by DC sputtering are as follows: flow 10SCCM argon gas, power 20W, sputtering 30s, and deposit a layer of Ag nanoparticles on the surface;

[0042] (5) Annealing treatment at an annealing temperature of 200°C and a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesoporous | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com