Wet etching equipment

A technology of wet etching and equipment, which is applied in the field of flat-panel display manufacturing. It can solve the problems of uneven flow of liquid medicine, easy occupation of space, and different overlapping areas, so as to reduce the generation of mura, reduce cost and time, and reduce the number of machines. structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with the embodiments of the present invention and the accompanying drawings.

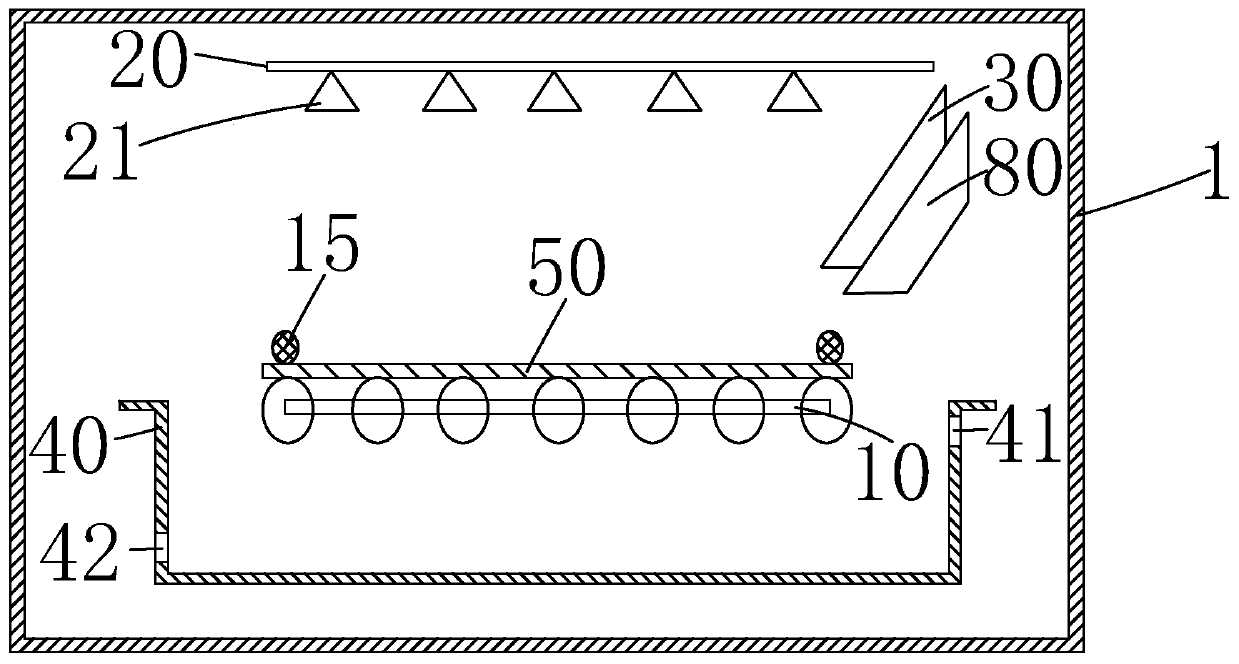

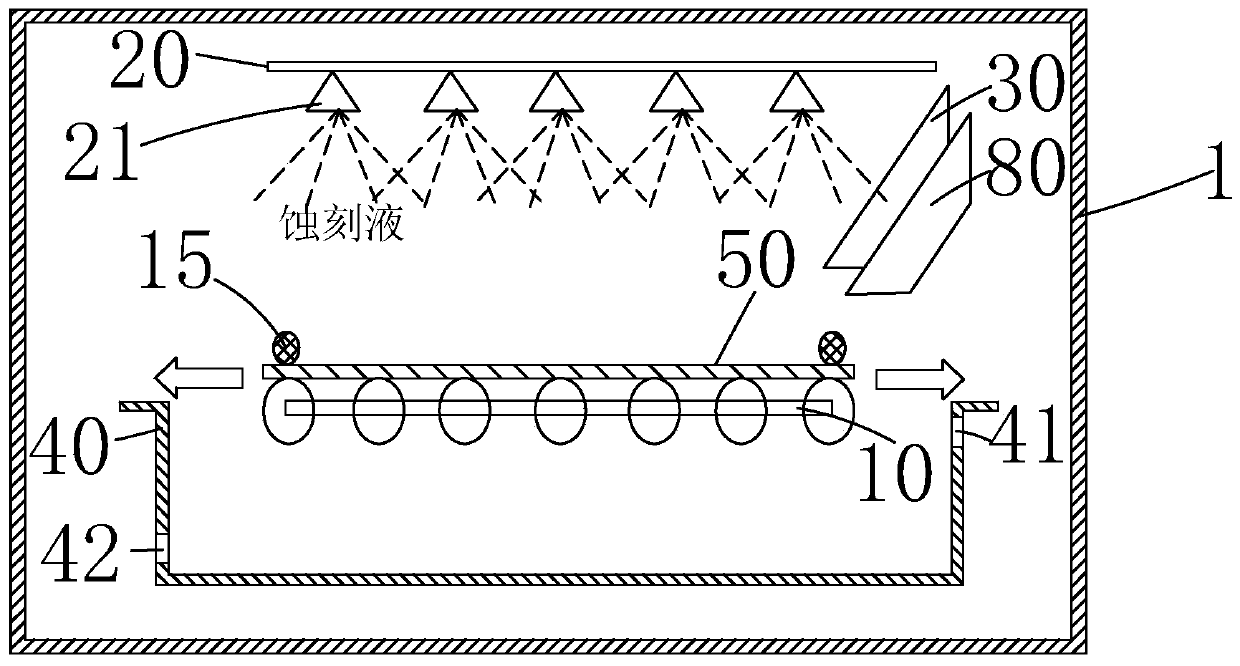

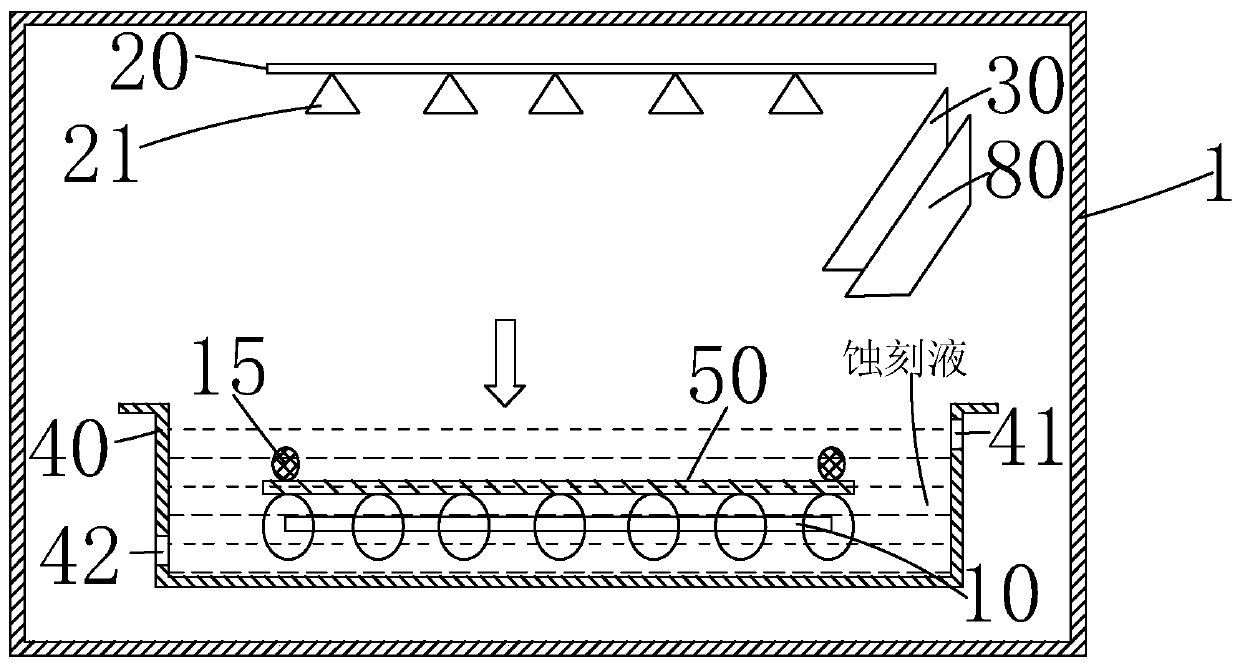

[0025] see figure 1 , the present invention provides a wet etching device, comprising an etching chamber 1, and a carrying platform 10 installed in the etching chamber 1, a spray pipe 20, a liquid knife 30, and an etching tank 40, wherein the carrying platform 10 is used On the carrier substrate 50, the spray pipe 20 is arranged above the carrier table 10 for spraying etching solution on the surface of the substrate 50, and the liquid knife 30 is arranged between the carrier table 10 and the spray pipe 20 for After coating the etching solution on the surface of the substrate 50 , the etching tank 40 is disposed under the carrier table 10 for containing the etching solution and the substrate 50 .

[0026] The wet etching equipment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com