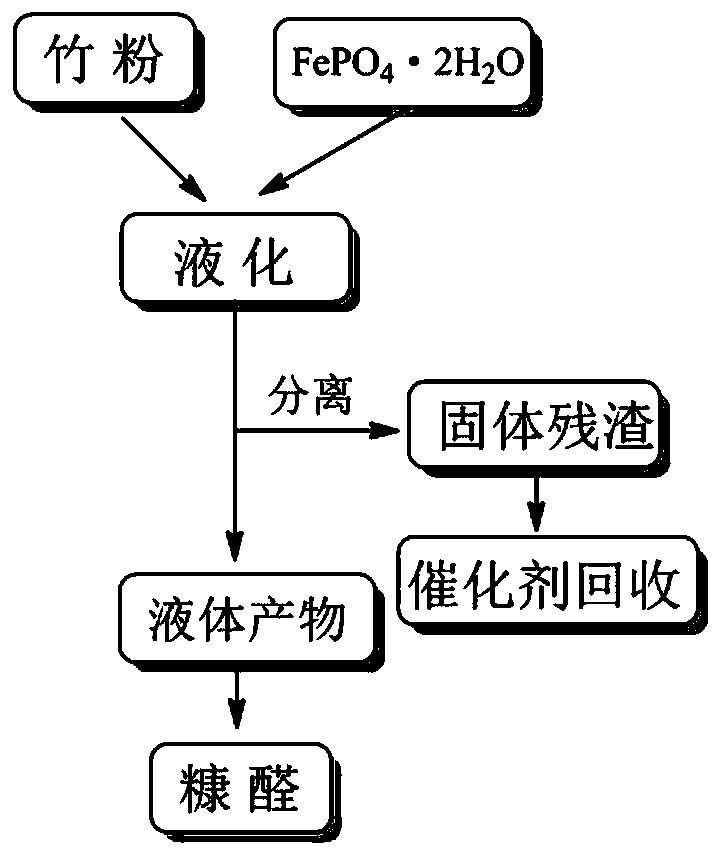

A kind of method that ferric phosphate catalyzes the liquefaction of bamboo powder to prepare furfural

A technology of iron phosphate catalyzing bamboo and furfural, applied in the direction of organic chemistry, etc., can solve the problems of easy corrosion of equipment, low catalytic activity, difficulty in recovering inorganic acids and Lewis acids, etc., and achieves continuous, separation and recovery, equipment technology Flexible and economical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Bamboo powder is obtained by crushing bamboo chips to 10-200 mesh. In a 100mL autoclave, weigh 1g of bamboo powder, 0.5g of FePO 4 2H 2 O, 3.5g NaCl, 10mL deionized water and 30mL tetrahydrofuran were measured with a graduated cylinder. Cover the still lid tightly, and replace the air in the reaction kettle with nitrogen for 4 times. Then, turn on the condensing device and power supply of the reactor, set the reaction temperature to 160° C., and the stirring speed to 700 rpm. After heating up to 160°C, keep the temperature constant for 1 hour. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The remaining solid product and liquid product after the reaction were taken out, and the solid product and liquid product were separated using a Buchner funnel.

Embodiment 2

[0020] Bamboo powder is obtained by crushing bamboo chips to 10-200 mesh. In a 100mL autoclave, weigh 1g of bamboo powder, 0.5g of FePO 4 2H 2 O, 3.5g NaCl, 10mL deionized water and 30mL tetrahydrofuran were measured with a graduated cylinder. Cover the still lid tightly, and replace the air in the reaction kettle with nitrogen for 4 times. Then, turn on the condensing device and power supply of the reactor, set the reaction temperature to 170° C., and the stirring speed to 700 rpm. After heating up to 170°C, keep the temperature constant for 1 hour. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The remaining solid product and liquid product after the reaction were taken out, and the solid product and liquid product were separated using a Buchner funnel.

Embodiment 3

[0022] Bamboo powder is obtained by crushing bamboo chips to 10-200 mesh. In a 100mL autoclave, weigh 1g of bamboo powder, 0.75g of FePO 4 2H 2 O, 3.5g NaCl, 10mL deionized water and 30mL tetrahydrofuran were measured with a graduated cylinder. Cover the still lid tightly, and replace the air in the reaction kettle with nitrogen for 4 times. Then, turn on the condensing device and power supply of the reactor, set the reaction temperature to 170° C., and the stirring speed to 700 rpm. After heating up to 170°C, keep the temperature constant for 1 hour. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The remaining solid product and liquid product after the reaction were taken out, and the solid product and liquid product were separated using a Buchner funnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com