Film coating premix agent of probiotic preparation, as well as preparation method and application of film coating premix agent

A probiotic preparation and film coating technology, which is applied in the field of film coating premix for probiotic preparations and its preparation field, can solve the problems of reduced survival rate of probiotics, limited acid resistance, influence on microbial activity and the like, and achieve acid resistance. Strong, stable and easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

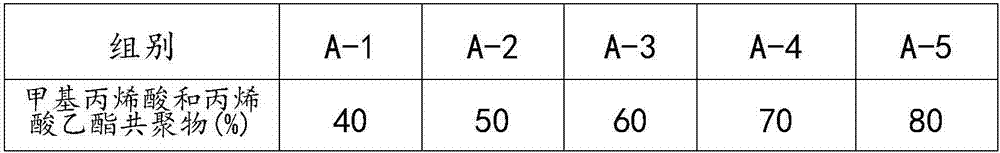

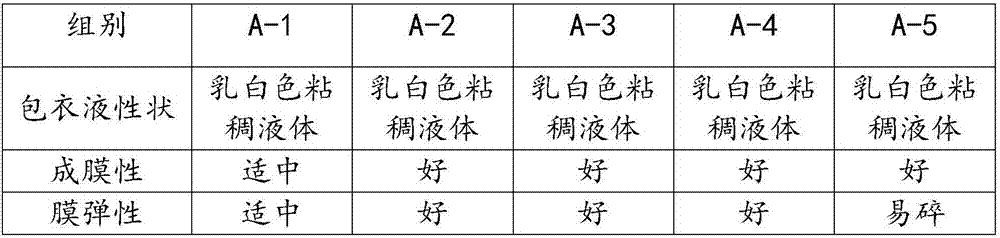

[0074] The film coating premix of probiotic preparations, by mass percentage, includes:

[0075] Methacrylic acid and ethyl acrylate copolymer 52%;

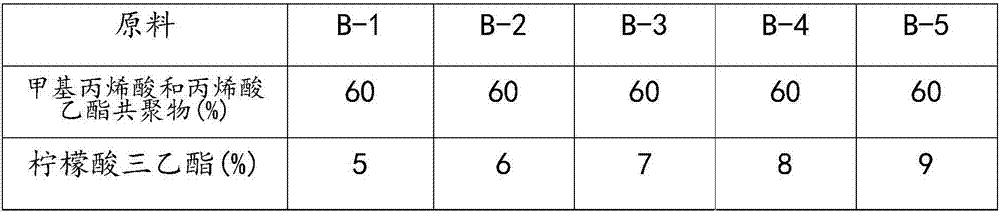

[0077] Plasticizer 6%;

[0078] Anti-sticking agent 11.95%;

[0079] Simethicone 0.05%.

[0080] In this embodiment, the ratio of methacrylic acid and ethyl acrylate copolymer is 1:1 in mass percent.

[0081] As described in this embodiment, the plasticizer is triethyl citrate.

[0082] As described in this embodiment, the anti-sticking agent is stearic acid.

[0083] Described in the present embodiment, a kind of manufacturing method of the film coating premix of probiotic preparation comprises the following steps:

[0084] Weigh methacrylic acid and ethyl acrylate copolymer, talcum powder and stearic acid according to the mass percentage and place them in a high-efficiency granulator, turn on the stirring equipment, and stir and mix for 10 to 15 minutes to make them uniform. Add triethyl citrate...

Embodiment 2

[0088] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

[0089] The film coating premix of probiotic preparations, by mass percentage, includes:

[0090] Methacrylic acid and ethyl acrylate copolymer 56%;

[0091] Talc 28%;

[0092] Plasticizer 7%;

[0093] Anti-sticking agent 8.9%;

[0094] Simethicone 0.1%.

[0095] In this embodiment, the ratio of methacrylic acid and ethyl acrylate copolymer is 1:1 in mass percent.

[0096] As described in this embodiment, the plasticizer is triethyl citrate.

[0097] As described in this embodiment, the anti-sticking agent is stearic acid.

[0098] Described in the present embodiment, a kind of manufacturing method of the film coating premix of probiotic preparation comprises the following steps:

[0099] Weigh methacrylic acid and ethyl acrylate copolymer, talcum powder and stearic acid according to th...

Embodiment 3

[0103] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

[0104] The film coating premix of probiotic preparations, by mass percentage, includes:

[0105] Methacrylic acid and ethyl acrylate copolymer 69.9%;

[0106] Talc powder 20%;

[0107] Plasticizer 8%;

[0108] Anti-sticking agent 2%;

[0109] Simethicone 0.1%.

[0110] In this embodiment, the ratio of methacrylic acid and ethyl acrylate copolymer is 1:1 in mass percent.

[0111] As described in this embodiment, the plasticizer is triethyl citrate.

[0112] As described in this embodiment, the anti-sticking agent is stearic acid.

[0113] Described in the present embodiment, a kind of manufacturing method of the film coating premix of probiotic preparation comprises the following steps:

[0114] Weigh methacrylic acid and ethyl acrylate copolymer, talcum powder and stearic acid accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com