Paper recycling device

A processing device and fiber layer technology, which is applied in the field of paper regeneration processing devices, can solve problems such as winding, achieve the effects of reducing mechanical load, improving writing feel, and improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

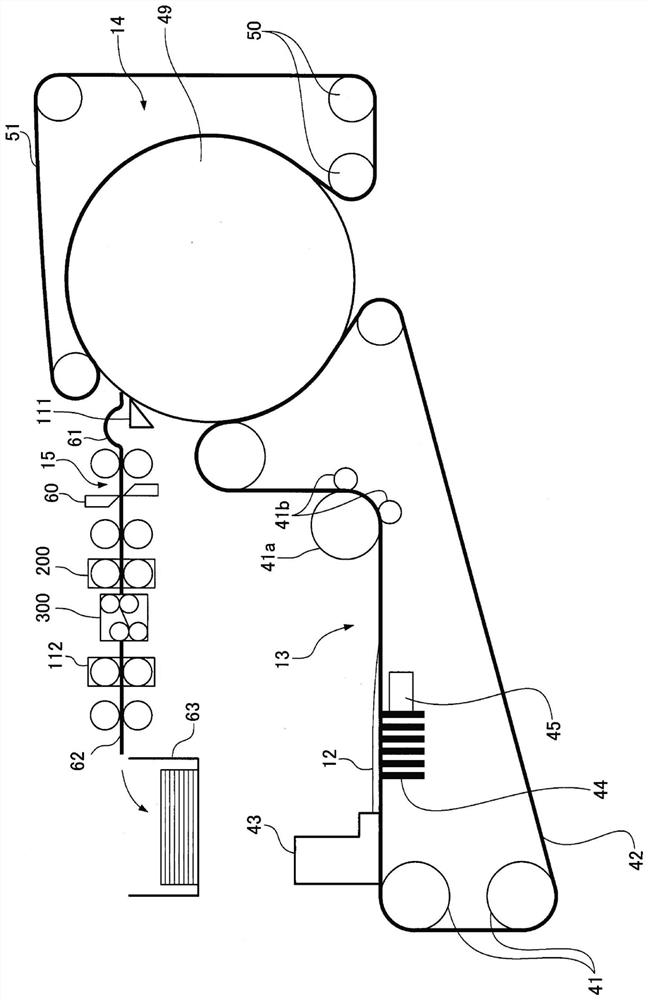

[0022] Embodiments of the present invention will be described below with reference to the drawings. Such as image 3 As shown, the papermaking part 13 constitutes a fiber layer forming part for forming a fiber layer of regenerated fibers. That is, the papermaking part 13 manufactures the wet paper 12 which is a fiber layer from the deinked pulp suspension which is a paper regeneration raw material.

[0023] The papermaking unit 13 has: a papermaking wire 42 made of a mesh belt, which is erected between a plurality of rollers 41 in a circular track shape; and a headbox 43, which pours the deinked pulp suspension onto the papermaking wire. 42 on.

[0024] The circular track of the papermaking wire 42 includes: a going portion from the headbox 43 to a drying roll 49 described later; a transfer portion covering a part of the drying roll 49; and a return portion returning to the headbox 43 from the drying roll 49 .

[0025] In the outbound portion of the papermaking wire 42 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com