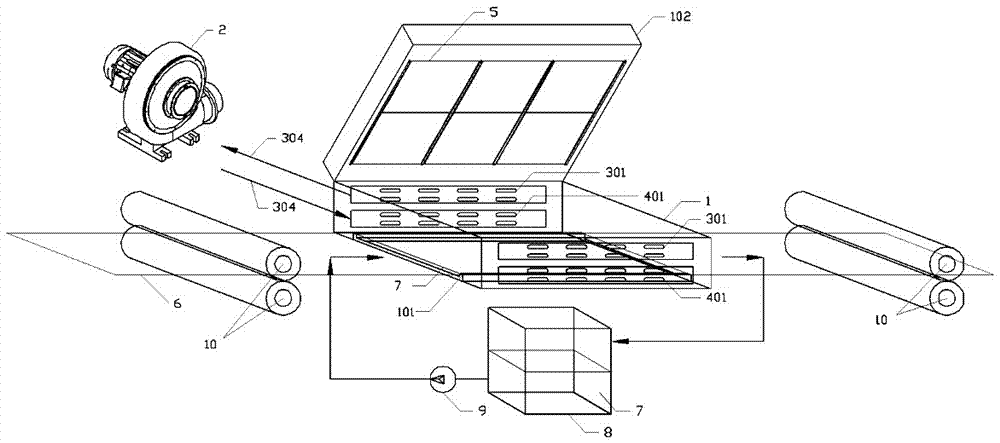

Device and method for recycling hot gas and reaction liquid in thin-film deposition by water-bath method

A technology of hot gas circulation and reaction liquid, applied in electrical components, liquid chemical plating, climate sustainability, etc., can solve the problems of limited development and application, easy loss of ammonia water, waste of raw materials, etc., to shorten time and reduce heterogeneity. The effect of reaction and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

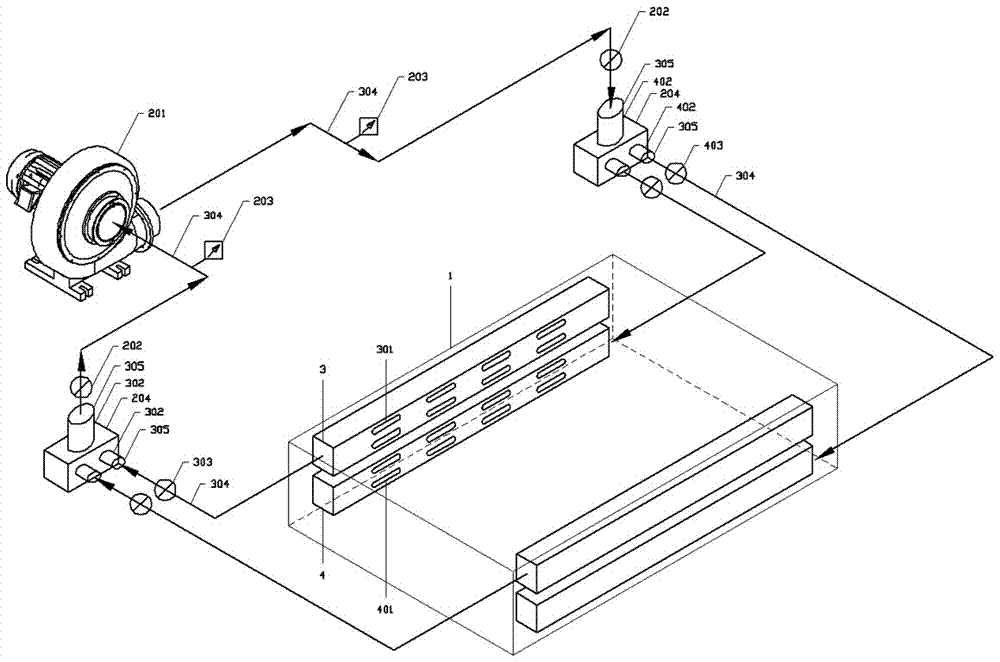

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of flexible substrate: A polyimide film (PI) with a thickness of 50 μm was selected as the substrate of the flexible thin film solar cell module, and a uniform 0.5 μm layer was plated on the substrate by the measurement and control sputtering method and the vacuum thermal evaporation method. A Mo layer and a 1.5 μm CIGS layer were used to fix the substrate on the transport device.

[0044] (2) Preparation of reaction solution: Mix zinc sulfate, ammonia water, thiourea, hydrazine, and ultrapure water in a certain proportion to make a reaction solution, and then add it to the mixing box. The concentration of Zn2+ in the reaction solution is 0.02M; the concentration of ammonia water is 1M, the concentration of thiourea is 0.01M, and the concentration of hydrazine is 0.15M.

[0045] (3) Hot gas recycling device: Turn off the hot gas recycling device, and the gas in the reaction tank is directly discharged without circulation.

[0046] (4) Deposition of ZnS:...

Embodiment 2

[0049] (1) Preparation of flexible substrate: the same as in Example 1.

[0050] (2) Preparation of reaction solution: Same as Example 1.

[0051] (3) Hot gas recycling device: Turn on the hot gas recycling device, set the hot air pressure to 3~5 KPa, and the gas in the reaction tank starts to recover and circulate.

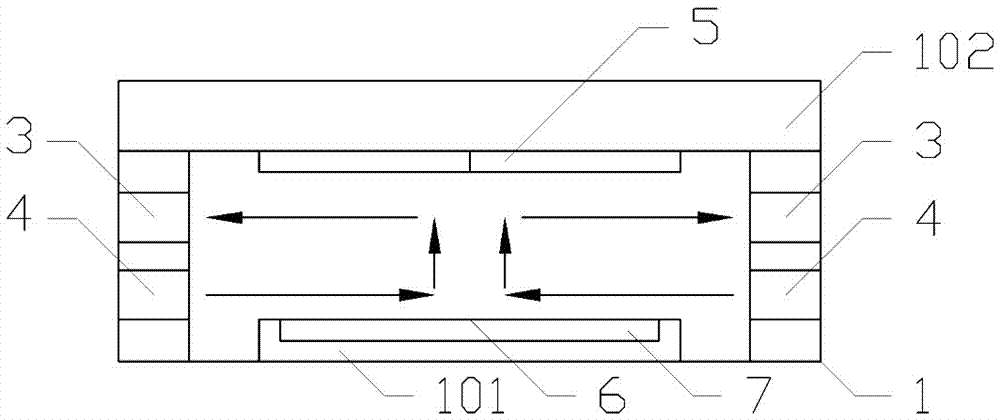

[0052] (4) Deposition of ZnS: pump the reaction liquid to the reaction tank through the reaction liquid pump, set the flow rate to 3~10 L / min, set the temperature of the heating plate to 350 °C, the width of the reaction tank is about 350 mm, and the length of the reaction tank is about 350 mm. 6 m, the flexible substrate conveying speed is 0.1-1.5 m / min, and a high-quality ZnS film with uniform thickness can be obtained at the back end of the reaction tank in 30 min.

[0053] If the hot gas recycling device is turned on, the hot gas will be recycled and not discharged directly. After about 30 minutes, the pH value of the reaction solution will be stable at abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com